High-Pressure Laminates Wholesale Price from China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Description of HPL:

HPL are high quality decoration material , which are widely applied to furniture,kitchen cabinet,cupboard, countertop, window, door skin, wall lining, partition, ship lining ,ceiling, lift lining, shop fitting,shelving, etc .

Fireproof board / refractory plate is base paper after melamine resin and phenolic resin processing, main physical properties is unfolded by the characteristics of the resins. After the melamine resin thermosetting moulding have luster good, good transparency, high surface hardness, wear-resisting, withstand high temperatures, impact resistance, surface pores small is not easy to be contaminated, chemical resistance, water resistance, resistance to solvent, flame resistance and other excellent performance, mechanical strength, electrical insulation, resistance to arc good and is not easy to aging. Phenolic resin thermoset molding after heat and hard performance. Two kinds of resin combination, fireproof board / refractory plate contains both the performance.

2.Feature of HPL:

1) Finishied via impregnating the decorative paper and kraft paper in melamine,drying and high temperature and presure

2) Outstanding resistance to abrasion,high tempreature,dirty,shocking,cigarette ignition and open flame

3) Exceptional mould proof performance ,has very wide application and very big market potential

4) Decorative surface material for both indoor and outdoor use

5) Widely used in surface decoration of rooms, offices, compartments, partitions, kitchens, sideboards, furniture and laboratory table tops

6) wear-resistant, fire-resistant, anti-static, chemical resistant

7) Acid resistance and alkali resistance

8) Abrasive resistance

9) Amazing colors and rich in colors. High glossy and matte is available.

10) Easy to clean

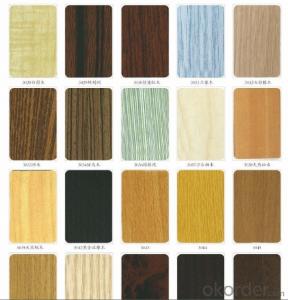

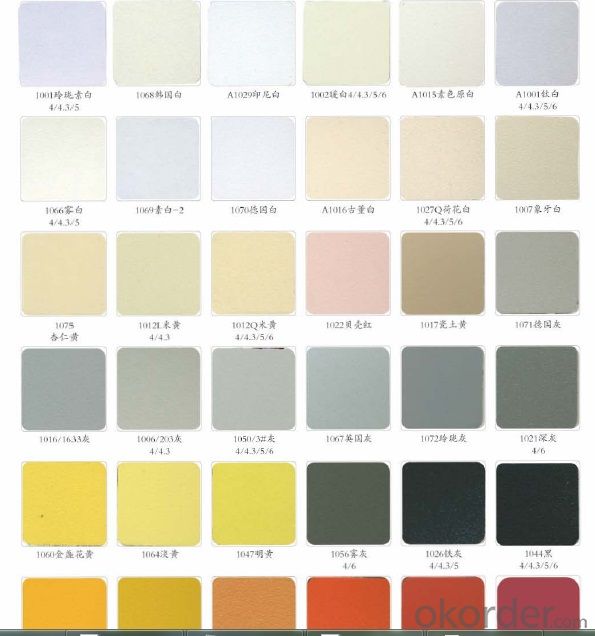

3.Images of HPL:

4.Specifications of HPL:

1. size

1220mmx2440mm 1220mmx3050mm 1310mmx2440mm 1310mm x3050mm

2. thickness

Standard HPL: 0.5mm~1.0mm.

Post-forming HPL: 0.5mm~0.6mm.

Metallic HPL: 0.7mm~1.0mm

Compact: 1.0mm~12mm.

3. color

Solid/plain color, fantastic color, wood grain color, metal, wooden veneer or customized color

4. surface finishing Glossy, Matt, Texture and some other special surfaces.

5. payment 1) T/T 30% in advance, 70% before shipment 2) L/C at sight

6. delivery time It depends on the specific order quantity

7.minimum order quantity 2000 PCS

5.FAQ

1. What kind of certificate do you have?

ISO9001, CE, UL,CARB, CNAS

2. What color can you produce?

Solid color wood grain color or according to customs' requirements.

3. How about the samples?

For the samples, it will be prepared ASAP.

4. Do you charge for the Samples?

According to our company policy, we will charge you the express fee in the first time but the sample will be free. While we start our business, we will reimburse the money for you

5. Can you produce according to customer's design?

Sure, we are professional manufacturer, OEM are welcome. While the beginning you need to pay the moulded open fees and Orders meet the minimum ordering quantity of special products

- Q: Are you using fireproof materials for decoration?

- Home furnishings generally use wooden keel to fight the frame, with a special expansion bolts fixed, and then decorated with five decorative board, face seal gypsum board. The use of wood is not equipped with fire performance, but the need to brush on the surface of these materials, a layer of fire retardant coating has reached the effect of fire. Fire factory in OKorder high-cut board for cunning in the tooling requirements than home improvement rigorous.

- Q: In addition to rock wool sandwich panels which plate

- Foam glass plate Glass wool board Expanded perlite plate

- Q: Is it necessary to provide a fireproofing material for decoration works? Such as the use of the hanging plate.

- This is a fire-proof panel production plant inspection report can be recommended to use the quality of the grand Huayuan fire-retardant board the country's first full-bodied Hong Kong Kuang Fan Songs with the Ministry of products that the national test A1 qualified

- Q: Building ceiling material fire rating

- Divided into four grades, non-flammable, flammable, flammable, flammable...

- Q: Decoration materials fire rating

- Class A: incombustible Building materials: almost no burning material. A1 level: non-combustible, can not afford to fire A2 level: non-combustible, to measure smoke, to qualified. B1 level: flame retardant building materials: flame retardant materials have a better flame retardant effect. It is in the air in case of fire or in the role of high temperature difficult to fire, it is not easy to spread, and when the fire destroyed after the fire immediately stop. B2 grade: flammable building materials: combustible materials have a certain role in flame retardant. In the air in case of fire or under high temperature will immediately fire burning, easy to lead to the spread of fire, such as wooden pillars, wooden truss, wooden beams, wooden stairs and so on. B3 level: flammable Building materials: no any flame retardant effect, easy to burn, fire risk is great.

- Q: What are the fireproof materials?

- Water and wet cotton quilts

- Q: Indoor to do with the gypsum board or good or good use of fire board board, fire board is made of what material ah how environmental

- The key depends on the appearance of the cut off the preparation of how to deal with. If the appearance of the surface to be directly brushing latex paint, then directly with the wooden keel frame, and then seal the gypsum board can be, and if you hang the TV, when the framework, in the appropriate location fixed a large core board, Gypsum board is to withstand the TV) If the appearance of the facade to think about the paint, then use the wooden keel to do the framework, and then Daixinban substrate, do the decorative panels, and finally do paint. Advantages and disadvantages of fire board: 1, fire board, that is, we usually heard in the life of the fire board, usually the use of kraft paper or titanium powder in the phenolic resin and melamine impregnated under high temperature after the pressure made of a Plate type, belonging to a refractory building materials. Its insulation, heat insulation is six times the glass, clay three times, ordinary concrete ten times. 2, ALC board is a silicate material, there is no aging problem, it is not easy weathering, is a durable building materials, the normal life and all kinds of permanent buildings can match the life span. 3, ALC board is not radioactive, there is no harmful substances spill. Aerated concrete fire board superiority: in the production process, there is no pollution and hazardous waste generated. When used, there is no radioactive material and harmful gases, even at high temperatures and in the fire. Each of the independent micro-bubbles, so that aerated concrete products have a certain impermeability, to prevent water and gas penetration, green.

- Q: What kind of good insulation materials for cold storage?

- Polyurethane spray ah urethane large board rock wool board glass wool board

- Q: If not expensive to buy one of the best, but OKorder did not find. Because I have some important documents, documents, money, worry about living somewhere a day of fire. In case, I would like to put these important objects inside the bag can be fire. Not much of a thing, a folder size of the bag is enough. What materials can be used to make one way? Can also wrap the line, but can often open, not like the tape that ridge set up the plateau dry chop suck raft by the sample sealed. Thank you. More

- You can use concrete pouring a box ridge set hoarding plateau dry chop suck raft by the child, in addition to a concrete door can be, but relatively heavy, but can guarantee that will not be burned bad! Concrete is best at 20cm or more.

- Q: Fire-resistant coatings are generally water-based or oily

- Common fire-resistant coatings on the market are also water-soluble (oily). Fire retardant coating from the dispersion medium can be divided into: water and solvent-based two. Water-based fire retardant coating: water as a dispersion medium, the emulsion for the film-forming material, in a variety of flame retardants, filler composition of water-based fire retardant coating. Solvent (oil) fire retardant coating: organic solvent for the thinner, resin for the film-forming material, in a variety of flame retardants, fill the composition of solvent-based fire retardant coating. The difference between the two: water-based fire retardant paint green, environmentally friendly fire-resistant coating, is the national and industry recommended species. Solvent-based fire retardant coating because of the organic film in the process of drying, benzene, xylene and other needs to be volatile, so people and the environment have a certain impact, but in a certain environment, solvent-based fire retardant coating fire resistance, water resistance Chemical resistance is water-based fire retardant coating can not reach. With the continuous progress of technology, the future may be completely eliminated solvent-based fire retardant coating.

Send your message to us

High-Pressure Laminates Wholesale Price from China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords