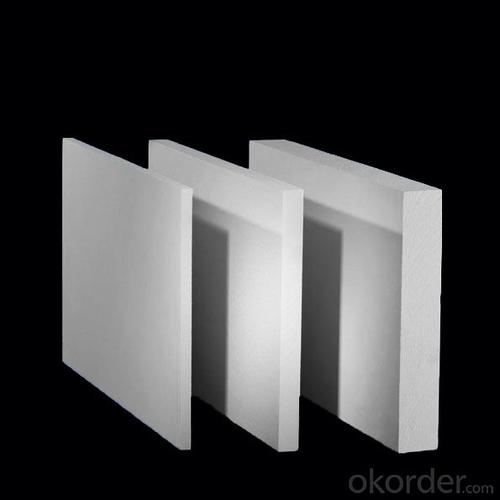

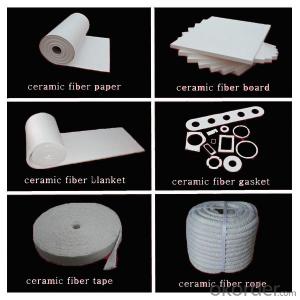

Ceramic Fiber Board with SGS Approved

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 0.5

- Supply Capability:

- 80 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information

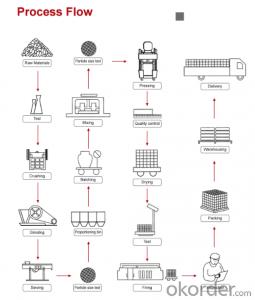

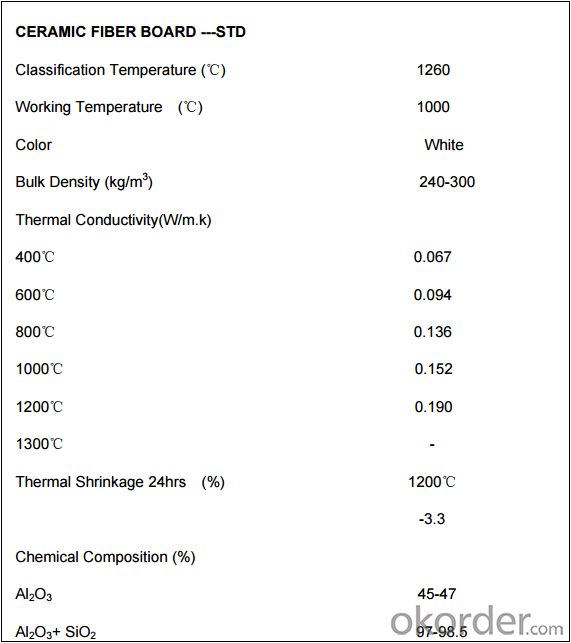

CMAX ceramic fiber board are manufactured in a wet vacuum forming process by blending the chopped ceramic fiber with inorganic or organic binders for excellent abrasive resistance at high temperature.

The products are classified as STD, HP, HA, and HZ respectively corresponding to different maximum service temperature 1000 centigrade,1100 centigrade ,1200 centigrade and 1350 centigrade.

Feature

Low thermal conductivity

Excellent thermal shock resistance

Excellent chemical stability

Even density and thickness

Non standard sizes are available upon request

Application

Hot air duct ling

Shuttle kiln with high gas velocity

Laboratory furnace

Kiln car insulation

Die-cut high temperature seal

Note: Technical Data are typical results from test pieces. This information, subject to change,is offered solely for your consideration. Users of our products should make their own tests todetermine the suitability of each product for their particular purposes.

- Q: Is the material inside the fire door gypsum board?

- No, it is fire board (perlite).

- Q: The fire resistance of building materials includes the nature of building materials

- Recommended answers are good

- Q: In addition to rock wool sandwich panels which plate

- The The

- Q: Polyurethane fireproof material really effective?

- This ad, I also served

- Q: Phenolic insulation board is B1 grade fireproof material

- A2 We specialize in the production of phenolic insulation board modified phenolic insulation board

- Q: Rubber insulation material fire it?

- Fire (he is only flame retardant and not non-flammable) B1 and B2 level Ji Ji rush to kill the ghosts only Han Li is not the flame retardant coefficient of low smoke density of a standard is not a standard in a density (density related to the effect of insulation ) Sure that you have fire against you

- Q: What is the meaning of the plastic raw material fire rating HB?

- Plastic flame retardant grade from HB, V-2, V-1 to V-0 step by step increase: HB Hu Gong Hong Kong folder fan locust song Wei attack: UL94 and CSAC22.2No0.17 standard in the bottom of the flame retardant grade. It is required that for samples of 3 to 13 mm thick, the burning rate is less than 40 mm per minute; samples less than 3 mm thick, the burning rate is less than 70 mm per minute; or extinguished before the 100 mm mark. V-2: After two 10-second burn tests on the sample, the flame is extinguished in 60 seconds. There can be a burning thing falling. V-1: After two 10-second burn tests on the sample, the flame is extinguished in 60 seconds. Can not have a burning thing falling. V-0: After two 10-second burn tests on the sample, the flame is extinguished in 30 seconds. Can not have a burning thing falling. Clearly please adopt!

- Q: Ul94v-0 refers to the fire level or a material

- Is a flame retardant material, flame retardant grade requirements are V-0.

- Q: Plastic products in the classification of fire levels is how the standard ah?

- Flammability rating, that is, the material has or the material has been treated with a postponement of the nature of the flame spread, and the division of the system. 1, the plastic flame retardant grade from HB, V-2, V-1 to V-0 step by step increase: HB: UL94 and CSAC22.2No0.17 standard in the bottom of the flame retardant grade, requiring for 3 to 13 mm thick Sample, burning speed less than 40 mm per minute; less than 3 mm thick sample, burning speed less than 70 mm per minute; or 100 mm mark before extinguishing. V-2: After two 10-second burn tests on the sample, the flame is extinguished in 60 seconds. There can be a burning thing falling. V-1: After two 10-second burn tests on the sample, the flame is extinguished in 60 seconds. Can not have a burning thing falling. V-0: After two 10-second burn tests on the sample, the flame is extinguished in 30 seconds. Can not have a burning thing falling. 2, UL classification of plastic material burning grade? UL is the plastic material standard test piece after the flame burning after the spontaneous combustion time, spontaneous combustion speed, falling particles to determine the state of the burning of plastic materials, according to the level of good and bad, followed by HB, V2, V1, V0, 5V, There are very thin material grades VTM-0, VTM-1, VTM-2, and foam material grades HBF, HF-1, HF-2.

- Q: Is the soundproof cotton a fireproof material?

- Can be said to be ,,, but not that he will not burn, I tried to burn with fire, when we still fire when he was still burning, the fire that went to immediately off, that he is flame retardant of,,,

Send your message to us

Ceramic Fiber Board with SGS Approved

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 0.5

- Supply Capability:

- 80 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches