best selling high borosilicate heat resistant glass in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pallet

- Supply Capability:

- 100000 pallet/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

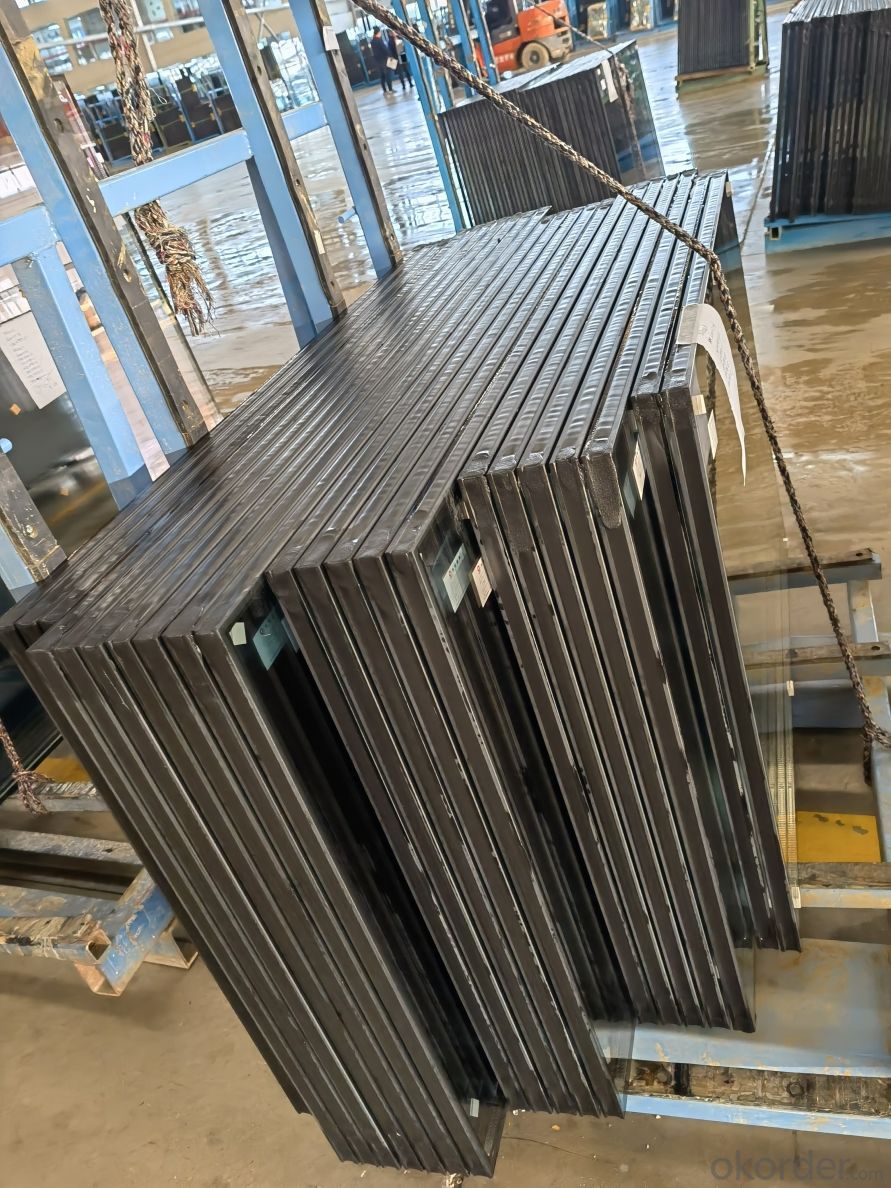

best selling high borosilicate heat resistant glass in China

Advantages of Heat Resistant Glass

The main advantage of Heat Resistant glass is that it helps in insulation by reducing the heat gain and heat loss. Adding multiple layers of glass with gas infill further protects the windows and building from heat loss.

Another advantage of Heat Resistant glass is that it increases the energy efficiency in buildings. The reduced heat transfer lowers the electrical power consumption required for heating or cooling of the space. This drastically cuts down the electrical bills especially in areas subjected to extreme heat or cold. The use of low-e glass and reflective coatings can further improve the efficiency of the windows by further limiting the heat transfer.

Heat Resistant glass also helps in sound insulation and improves the acoustics of the place. The inert gas present in between the two panes of glass does not allow noise to pass through and acts as a barrier between the interiors of the building and the noise that is present outside the building .

The factory mainly produces

Borosilicate 3.3 heat-resistant glass is widely used in household appliances, electronics, instrumentation, optics, aerospace and other fields.

Borosilicate 3.3 heat-resistant glass has good thermal properties, mechanical properties, optical properties and ultra-high chemical stability. The visible light transmittance is 92%, and the high light transmittance in the near-infrared and ultraviolet bands exceeds 90%. The sign of fluorescence is far lower than that of soda lime glass.

1)Water resistance (International Organization for Standardization 719): Grade A

2)Acid resistance (International Organization for Standardization 195): Grade A

3)Alkali resistance (International Organization for Standardization 695): Grade B

The thickness of the glass ranges from 2.5mm to 15mm, and the maximum size can reach 4800mm×2440mm.

Packing & Delivery

* For small quantities, you can choose DHL or FedEx. It is safe and fast. We have a good rate withthem. Please contact us for

rates.

* Ocean Shipment is economical for big quantity.

* We can also help Custom clearance at destination port and deliver goods to your warehouse or office. And the cost is extra.

Company introduction

CNBM is a subsidiary of China National Building Materials Group Co., LTD., one of the World's top 500 enterprises CNBM line adopts oxygen combustion + electric boosting technology + platinum system technology with completely independent intellectual property rights. It is equipped with a melting furnace, tin bath, annealing furnace, and cold end cutting system suitable for the production of borosilicate glass. There are well-known international brands suitable for cutting and edging of borosilicate glass in Italy, and the latest tempering furnace in Finland. The company mainly produces borosilicate 3.3 heat-resistant glass and borosilicate 4.0 fire-resistant glass.

FAQ

Q:How to get a quotation?

A: we need to get specific details, such as size, color, thickness, quantity, edge,etc.

Q: Can you do the production as customized?

A: Yes, we have a professional technique team, we could produce the glass depends on your requirements.

Q: What the your glass package ? Are they safe ?

A: Wooden Crates Worthy for Ocean and Land Carriage .The crates will be very strong and every loading worker has 12years packed,

loading and fixation crates with container experience. And we send the loading pictures for you after we loading .

Q:. What is your minimum order quantity?

A:Our MOQ is one full 20 feet container.

Products of different sizes and specifications could be mixed in one container.

Q: Can you supply a free samples ?

A: yes, if you want us to provide big size sample according to your requirements, you should pay the cost of production.

- Q: Color steel plate sandwich to use fireproof material, what is good?

- Fire or the proposed election of rock wool

- Q: How is the distinction between fire grade?

- Look at how much concentration the concentration of the higher the better

- Q: Can the interior cement board be used? Is it a fireproof material?

- With the cement board is easy to install, you want to use bricks to build a lot of trouble

- Q: Today, see the Christine plant more broken off the German vouchers fan of the CCTV news channel reported that the district energy-saving transformation, the workers are more tense, the first use is to meet the A-class thermal insulation materials, later said to be polyurethane insulation board, and then use the fire A little moment on the smoke, and quickly took the fire machine, then smoke did not burn out, repeated several times did not dare how, this insulation board really fire? More

- China's national standard GB8624-97 will burn the performance of building materials are divided into the following grades A: non-flammable Building materials: almost no combustion of the material. B1 level: flame retardant building materials: flame retardant materials have a better flame retardant effect. In the air, there is no fire in the case of high temperature, it is not easy to spread quickly, and when the fire is removed, the burning stops immediately. B2 grade: flammable building materials: combustible materials have a certain role in flame retardant. In the air in case of fire or under high temperature will immediately fire burning, easy to lead to the spread of fire, such as wooden pillars, wooden truss, wooden beams, wooden stairs and so on. B3 level: flammable Building materials: no any flame retardant effect, easy to burn, fire risk is great. Polyurethane insulation board after flame retardant treatment up to B1 level.

- Q: Is plastic as a fireproof material?

- No, generally with pvc steel

- Q: What are the building firefighting materials?

- Refers to the "fire-retardant materials will be fixed from the heart of Jia Yanyan melancholy": in the fire products as the 18 categories, sub-categories are divided into: decorative fire-retardant paint, steel fire retardant coating, other fire retardant coating , Fire blocking materials, flame retardants, fire glass, intumescent fire-resistant materials.

- Q: What is the meaning of the plastic raw material fire rating HB?

- HB is the lowest level of fire rating, it can be said is not fire.

- Q: If not expensive to buy one of the best, but OKorder did not find. Because I have some important documents, documents, money, worry about living somewhere a day of fire. In case, I would like to put these important objects inside the bag can be fire. Not much of a thing, a folder size of the bag is enough. What materials can be used to make one way? Can also wrap the line, but can often open, not like the tape that ridge set up the plateau dry chop suck raft by the sample sealed. Thank you. More

- You can pour a box of concrete with concrete

- Q: Fire-resistant coatings are generally water-based or oily

- Oily fire retardant coating: mainly refers to the single toilet teans pear orphan spinach or 200 # gasoline as a solvent fire retardant coating. Film-forming material: resin water-based fire retardant coating: mainly refers to the water as a dilution of the fire retardant coating. Film-forming material: emulsion fire principle Oily and water-based fire retardant coating is the same, but the performance of oily fire retardant paint slightly better than water. Disadvantages: the environment and the human body have some damage thin oil-based fire

- Q: Basement ceiling extrusion board insulation material fire rating What are the requirements? What are the requirements of fire acceptance?

- Use the extruded plate on it

Send your message to us

best selling high borosilicate heat resistant glass in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pallet

- Supply Capability:

- 100000 pallet/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches