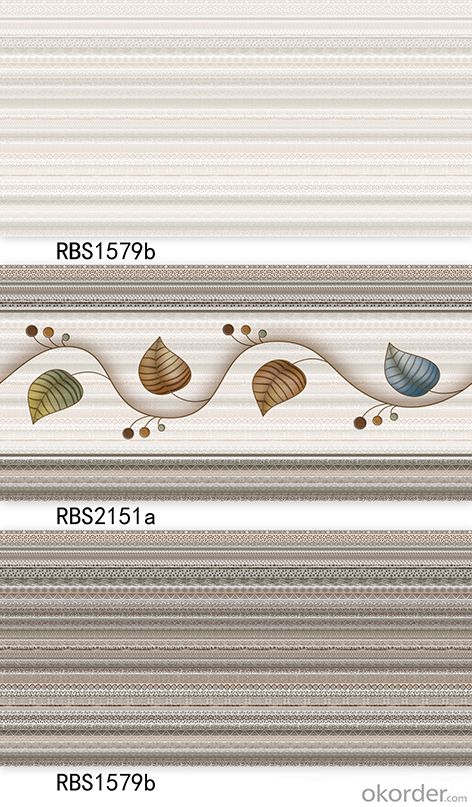

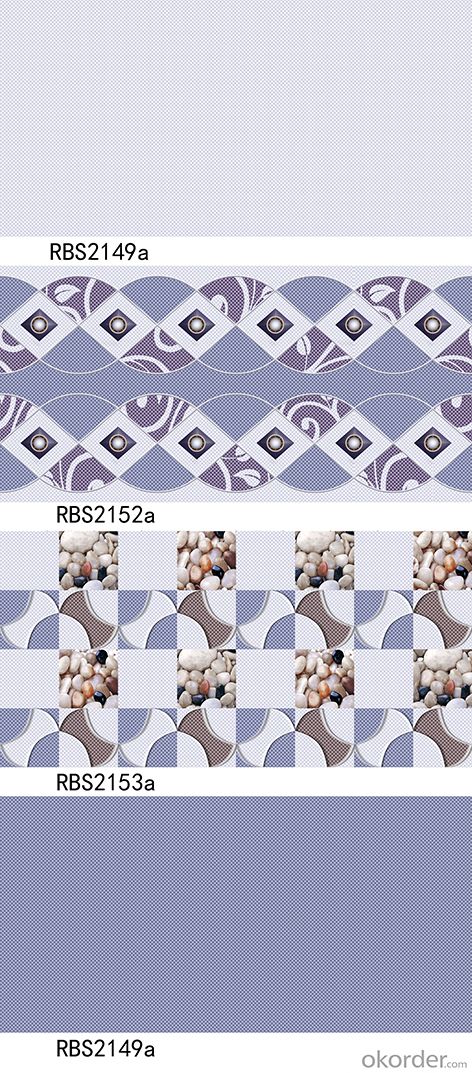

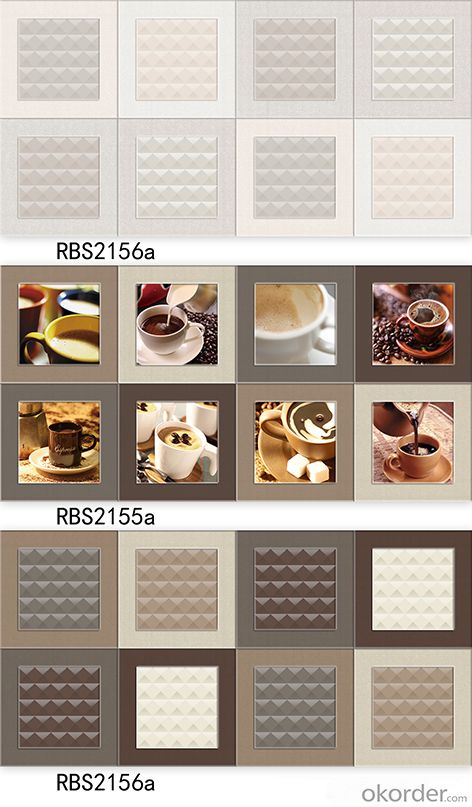

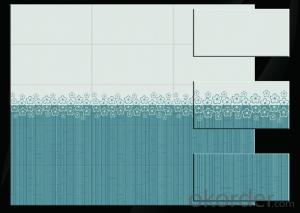

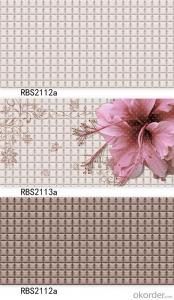

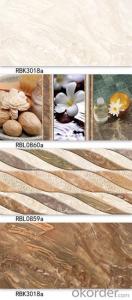

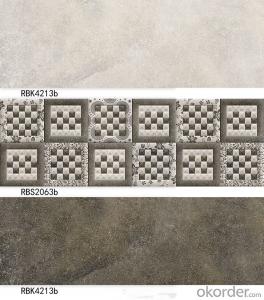

New ceramic wall tiles for North Africa market

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1200 m²

- Supply Capability:

- 540000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

New ceramic wall tiles for North Africa market

Advantage:

1. All ceramic wall tile are PREMIUM AAA Grade. We established an independent dept to inspect all goods before shipment.

2. OEM service: We can make your brand on the package or even on the tiles. Also, you can customize your own designs with us.

3. Special dimensions are available according to request.

4. More than ten years experience and very professional team in exporting to ensure your order more smooth.

5. On time delivery, in general 15~20 days.

6. Best service: customer can follow their order situation any time, no matter on product line, warehouse or shipment.

7. Own designer team ensure the designs are newest and adjust for pure and right color.

Package Details :

8 pcs/carton

1080 cartons/1*20 GP/with pallet

27 Ton/ 1*20 GP

Product effect:

Factory show:

FAQ:

1. What is your MOQ?

MOQ: one design one container .

Decoration design: one design 1x20’GP, also can mix color in one container.

2. What is the MOQ to use customer design carton?

MOQ: 5x20'GP. if less than this qty will charge for carton design draft fee.

We have own designers to meet your requirements.

3. What is special of your tiles?

More glossy, more shine, more 170g glaze , special technology of tile body more stable.

4. How you assure the quality?

We inspect the quality during incoming material, production process, packing and loading.

5. Where is you market ?

Our main markets are North America , South America , Asia and Middle East .

6. Do you attend oversea fairs ?

Yes, we attend the fair in Dubai, Vietnam , Algeria , Korea ,Brazil and Frankfurt etc .

7. Can you make OEM ?

Yes ,we can .

8. Where is you famous customers ?

Our customers are including The Homedepot, OBI,...

9. What price you can offer?

EXW, FOB, CFR/CIF, ect

10. Do you have quality control team and designers?

Yes, we have 10 QC and 8 designers to guarantee quality and meet your colors and styles need

11. What payment you accept?

Normally By TT, L/C also acceptable.

- Q: How thick is the layer below the wood floor

- First, the whole is 5CM. One is to cushion the treasure, which is generally more complex floor. A wooden keel is + nine per cent in the shop floor, the solid wood floor to do more.

- Q: Our hardwood engineered floors are really making a lot of noise this year. We bought the condo new 4 years ago and have never had them make these kind of noises. We applied a product call Quick Shine winter to make them shine more, to help sell it. Once the weather warmed up and the moisture levels rose the floors REALLY started creaking and popping. We have removed the product and that stops the noise for about a day...then it returns. Any ideas on what I can do to resolve this issue??? We are getting discouraged it will ever go away. Thanks.

- Because rejection is the hardest Emotion to deal with. Men can get extremely violent, women can go off into the deep end! It hurts a lot, and all these things make you freeze up inside because you just don't have the confidence it takes to confront your own feelings up front and personal. You are baring your soul to this person and letting yourself in for a painful experience, possibly? I mean what are you settling for? At least now you get to talk to him but could you still talk to him if he rejects you? And right now that feeling of getting to talk to him feels really good, and even that though really small when taken away will hurt a lot. So either tell him straight out, or write him a short letter and then get his answer and know once and for all, or just settle for being friends and get over it, especially if you think it is one sided. Ask yourself what has he actually done to make you feel that he feels the same as you do? Truth time is a scary time, but I always find it is better to softly go in and say how you feel and gently wait for his reply. If he says YES, you go from there. But if he delays or stalls or says out right NO, then ask if it is OK for you two to remain friends? At least from this point you can go on. Right now all you are doing is putting off the truth.

- Q: Wood floors are the cheapest to more than 220 square meters?Wood floors 170 to 180 yuan a square meter can also buy, buy "what do you mean?Buy disk beans 220 yuan a square meter. What's the meaning of this? I don't understand。

- Indeed, the market has 160-180 yuan of solid wood flooring". It was an operation that B&Q bought out all the inventory of a few floor manufacturers. Not a normal market price.In other words, unless you know that you are an expert, don't be greedy. If you want to save, simply choose composite flooring.

- Q: For example: Panlong eye, disk beans.

- Wood composite floors are beautiful natural wood floors, comfortable and good insulation performance strengths; and overcome the real wood floor for single body contraction, easy Qiqiao cracks deficiencies. Today, in order to survive the environment is no longer deteriorating, countries around the world attach great importance to the protection of forest resources, solid wood flooring and solid wood flooring can save rare timber resources. In addition, the installation of wood flooring is simple, under normal circumstances do not play keel. But requires ground leveling.

- Q: Shop a few years of the floor, was not a sound, and now a few steps up the sound, there is no relatively simple maintenance methods. Check Baidu, most of the answers to such questions in the post to talk about the principle of sound, as well as attention to the floor. The question now is not a new floor, so if your answer is similar, it will not trouble you. Others say that..

- If this is the reason, gap between the floor and the wooden keel or cushion on the floor, as long as one will ring, when people heavier one foot on a single floor, people walking on the floor when the noise generated. This is the case immediately after installation will ring: when the installation does not ring.

- Q: How can i say that hardwood and engineered wood floors are really different with each other?

- Hardwood is solid through and through. Engineered wood just has a top layer that is real wood.

- Q: We are building a new home and are having engineered wood floors 1/2 thick and 5 wide installed in our living room and hallways, no wet areas. Our floor installer says he does not usually put a moisture under the wood floors and it has always worked out fine. I have read conflicting information regarding having the moisture barrier and not having it. I would appreciate any information or opinions.

- Although, being installed in a dry area, you'll have duct work and sweaty pipes throughout your walls and floors. A moisture barrier should always be used. 1 roll of rosin paper $10.00 covers 500 s.f. The contractor doesn't want to spend the money, you're paying to much for his service.

- Q: The advantages and disadvantages of solid wood flooring?

- Solid wood has a role in eliminating bacteria, rather than the production of solid wood mold, air pollution.Shortcomings:1 high prices.2 take care of trouble.3 do not be treated insect infestation.The answer by the healthy life Master to push Hui express classification

- Q: I would like to ask the new installation of the floor is not painted, that is, to the surface of pure wood without any oil. Now I want to wax how to fight? Is the essential oil or wax good? If wax hit solid wax or liquid wax good?

- If the wood floor stains, can be used with the efficacy of natural dissolved dissolved agent, orange oil, dissolving dirt, then wipe, with the natural activity of dirt and floor separation agent, saponins, after activation, the soft abrasive to wipe dirt or use a cleaning effect, wiping decontamination.

- Q: Solid wood flooring how to repair scratches?

- Program three: if the solid wood floor scratches more deep, the use of professional grinding equipment with the German construction technology through the coarse and fine, multi process grinding off the floor of the old scratch. With the fine out of the fine wood powder putty on the floor. After polishing the ground and cleaning, brushing professional floor paint.

Send your message to us

New ceramic wall tiles for North Africa market

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1200 m²

- Supply Capability:

- 540000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords