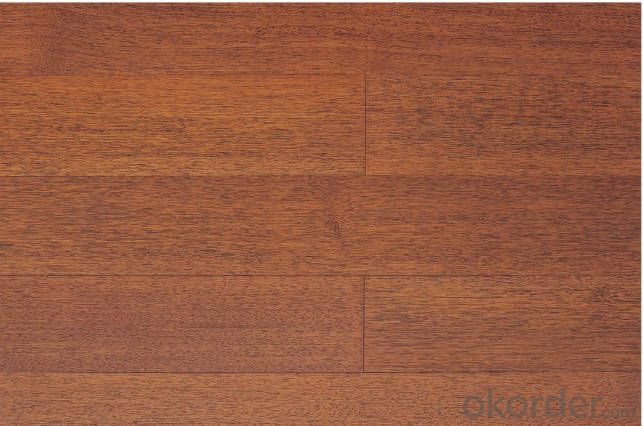

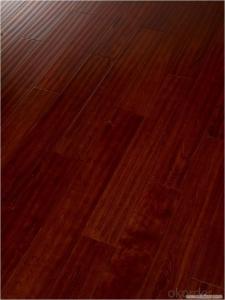

Yongsen Super Grade Red Merbau Wood Floor

- Loading Port:

- Nanjing

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m²

- Supply Capability:

- 2000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1、Material properties

Heartwood, sapwood yellowish white to gray; heartwood red brown to pale brown, with dark stripes. Growth wheel slightly obvious. The hole of the wood is of medium size, the size of the hole, the hole of the single hole and the short diameter column, and the content of the material. Axial parenchyma significantly, a ring tubular, wing, a wing and the wheel circle shape, thin wood ray, in great abundance; size of speckle is not obvious, the chord surface ripple No. Wood has luster, day special smell and taste; texture staggered, the structure is slightly thick, durable, strong. Hard material weight, high strength. The characteristics of the wood were very obvious in the yellow deposits in the tube, and the iron and water were easily to change.

Air dry density: 0.80-0.94g/cm3. Some rough and heavy structure and hard wood, beautiful and stable, with excellent wear resistance, anti position.

2、Product Characteristic

1, good material

Merbau as relatively high-end solid wood flooring in rare species, is north of pavement is a common species, shiny wood, no special smell and taste, structure slightly thick, strong oil, moisture resistance, anti termite properties, corrosion resistance, durability strong, hard material weight and high strength.

2, performance stability

Indian wood flooring material is stable, very difficult to deformation, cracking, can be called the stability of the solid wood floor, in theory, can be used for geothermal.

3, color is good

Printed on the wood floor pattern of the wood, the tree pattern is clear and beautiful, very distinctive, bright colors, fine workmanship, in appearance is very good

3、Parameter

Material: Merbau Wood

Origin: Zhejiang

Style: Modern

Standard: ISO90001

Applicable scope: bedroom

Pattern: Wood

Special purpose: wear resistant

Plate finish: good

Surface shape: paint

Residual depression: no

Formaldehyde release rate: E1

Resistance: good

Wear layer thickness: 3mm

Fading (stage): 1

Floor thickness: 18mm

Color: Red

Specifications: 910*125*18

4、Reference pictures

- Q: In my living room I have a brick fire place. When I install the wood floor I wood like it to appear as if the floor was installed first and then the brick fireplace on top of it. How do I cut the brick to slide the wood planks into the brick to achieve the look I want? What tool would be needed?

- Here are some tips: When cutting, saw into the prefinished side first to avoid chipping the finish. Always use a carbide-tipped blade. Use blue painters tape along the area to be cut to help prevent chipping the prefinished surface. Use a tapping block to move the hardwood into position. Do not hit the hardwood flooring directly. Keep the installation area as clean as possible. Do all the cutting in another area. Place tools on a piece of cardboard on top of your hardwood to avoid scratching or damaging your new floor. Always work from your subfloor, not your new hardwood floor. All of these tips came from the quick installation guide that I posted.

- Q: What is the difference between composite wood flooring and laminate flooring?

- Laminate flooring in the market a lot of names, according to national standards, its official name should be impregnated paper veneer laminate flooring1, excellent physical and mechanical propertiesThe first is the composite laminate flooring has high wear resistance, surface abrasion resistance is 10-30 times of ordinary paint wooden floor. The second is the product of the internal bond strength, surface bonding strength and impact toughness and other mechanical properties are better. According to the test, the surface resistance of composite reinforced wood floor is less than 1011, with good antistatic the performance, can be used as a room floor. In addition, composite wood floors have good resistance to corrosion, anti ultraviolet light pollution, cigarette burning resistance and other properties.2, there is a larger size and good dimensional stabilityTrends for large size floors and wood floors, with the size of the increase, the possibility of deformation is also increased. The composite wood floors with a high standard of material and reasonable processing method, has good dimensional stability, the floor size changes little indoor temperature and humidity caused. Low temperature radiant floor heating system architecture start with the composite wood floor is one of the most suitable floor materials.

- Q: hi,we bought this very nice red oak wood flooring. I think its some kind of engineered flooring. Anyway my question is do I need a moister barrier in my 2nd story rooms? The house was built in 2004 ( in case that matters) I know I have to put a foam down to reduce the noise but I don't think that the 2nd story has any moister.Oh by the way we are in south California so it is warm and dry most of the year.Thanks for all you help

- Moisture Barrier For Hardwood Floors

- Q: We're getting ready to remodel our kitchen and get conflicting advice on wood floors for a kitchen. I'd like to hear other people's experience with them.

- It relies upon on the dimensions of the room and the look you prefer to choose for, how plenty mild there is, and so on. My first theory grow to be linen (an off-white which may be as darkish as you like it to be, extra gray than yellow-cream). in case you like extra coloration than that, the white fixtures supplies you assorted flexibility. The cherry wood will in fact circulate with any coloration you prefer to paint, with some exceptions (i might circumvent crimson and orange, yet I probable does not paint partitions crimson or orange in any case, and with green you will must be careful to not look too Christmasy). The brighter and darker of a coloration you p.c.., the extra your fixtures will pop and happen interior the room, so it relies upon in case you like your fixtures to mixture into the partitions (probable starting to be the phantasm of a much bigger room), or in case you like it to stand out (additionally an rather great look). incredible hues would be extra pleased, the place darker hues would be extra person and subdued. What recommendations-set are you attempting to place for the period of for this room? maximum severely, what I continually tell human beings is, p.c.. a coloration that makes you satisfied, and then detect a version of it that works for the room.

- Q: most durable, Engineered, hardwood, bamboo, laminate floors?

- well hard wood is better. very expensive and if damaged hard to replace, but it lasts centuries and looks elegant. bamboo is much cheaper and easier to replace. i would get one that has a high durable gloss. that is your best protection from damage. rememeber to save some of what ever you buy so if ever needed you can replace it with the same kind of wood, and it will age and color the same.

- Q: How do I remove a glued down engineered wood floor on a slab foundation?

- hammer drill or jack hammer with a flat end. grind the glue off with a Diamond bit floor sander

- Q: How to solve the deformation of solid wood flooring?

- Plate moisture treatment methods: backplane mouth paint, wax coated, aluminum platinum, plastic coated with nano technology, etc.

- Q: I just removed carpet and found bad spots on sub-floor. We are cutting the bad spots out and replacing the wood, then the sub-floor will be nailed in good for stability. There are paint stains and other stains on the sub-floor, so we are going to lay plywood over it. Is this enough preparation for installing a glue down engineered wood floor? Any suggestions?

- rfg rg5 45tg5 4bgt vr

- Q: How to remove and dry out water stains from engineered ( not laminate , not true hardwood) wood floors?

- ok, so I'm trying to figure out your question....if it's a water stain then it's dry already and doesn't need dried out. If you have a stain of any kind then the wood might need to be sanded and revarnished. You should never use water on wood. If the floor is varnished then you'd only use a mop that's dampened with cold water or just a dust mop on it. And there is a Johnson & Johnson wax (gold something?) as I recall that is great on walls that are made of wood planks. If you're trying to dry out wood then having the heat on in the room for a while should do it. I lightly wash my rug every six weeks and it's dry in a couple of hours.

- Q: If I am not wrong Solid hardwood is one piece hardwood, engineering is multiple peice sheets glued on top of each other and Laminated is just plastic. Please correct me.Here is my situation.

- Hardwood flooring would give you the best resale for the money, but is expensive. Hardwood could run anywhere from 3 to 10 dollars per square foot. If it is scratched, it can be sanded and redone later on. Engineered is a hardwood floor, but cannot be refinished in case something happens. Also costs around 2.5 to 4 dollars square foot. Laminate looks a little cheaper, but will hold up better than hardwood or Engineered in the long run. I would suggest the Pergo 30 year warranty. Hardwood has to be nailed down to the floor, Engineered has to be tacked or glued down and laminate is free floating. In the case of the hardwood and engineered, you would have to pull up the ceramic tile. With laminate, you MAY not have to do that. Laminate in stock should cost around 2 to 4 dollars a square foot. A lot of laminate floors now look like the real thing. I suggest you do some window shopping to find out for yourself.

Send your message to us

Yongsen Super Grade Red Merbau Wood Floor

- Loading Port:

- Nanjing

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m²

- Supply Capability:

- 2000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords