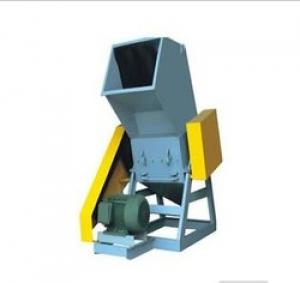

Plastic Retreading Equipment

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 50 Sets Per Month set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Detail: | sea worhty packing |

| Delivery Detail: | 15 days |

Specifications

output oil and carbon

1.Safety with full safety device,auto alarming

2.Low investement bring you high profit

Detailed Product Description:

GM series waste tyre retreading machine,carbon black refining machine, distillationn machine for diesel.

1.Automatically soldering technique, 100% quality guaranteed.

2.safety valves and emergency safety valves , 100% safe.

3.waste gas combusion systom, atteched dedusting systom, the discharge smoke is mainly vapour, no pollution at all.

4.CE certificate & ISO certificate

5.raw materails can be waste tyre, plastic, waste oil,make good use of waste materials.

- Q: Waste plastics recycling machinery market prospects, consult the people to answer

- Waste plastics recycling machinery? If the technology is more advanced, it is recommended to apply for a patent, and then apply for high-tech enterprises, and then apply for renewable resources recycling tax rebate eligibility......Can go to the relevant departments to consult.

- Q: and recycling of resources is the livelihood of the people, and sustainable development can not be separated from the contribution it has made. Heavy source machine 10The same is true of the historical mission, hoping to get the support and trust of the vast number of environmental protection friends, and work together to refuel it, will you? Our main products are stripping machine (stripping machine), crushing machine (crusher), PET cleaning equipment (dryer), sink, baler, knife grinder and so on.

- Advertising is reluctant to do, manufacturers are no strength of the manufacturers, the quality is difficult to guarantee

- Q: How do you make a tower out of old plastic bottles?

- Compared with the European Union and the United States, China has always had a tradition of waste utilization because of its large population and shortage of natural resources. So, this surplus investment, using international advanced technology of waste plastic recycling and processing enterprises, and those small workshops with simple equipment to produce simple cleaning and crushing processing of raw materials competition. The "crush" simple equipment, low labor costs, low processing cost, and do not need to pay taxes and sewage treatment, will raise the price of the raw material market, but the result is only a personal profit, to the society is easy to cause two pollution and environmental harm. According to Yao Yaxiong introduction, recycled polyester chip manufacturing cost itmake the same as with foreign countries, and more than 3 times the price of raw materials recycling is abroad. If you can't get a more favorable price than the raw material manufacturer, it will be difficult to take advantage in the fierce market competition. To obtain enough high-quality raw materials, itmake then set up professional recycling system of their own, in Beijing to have yaojiayuan and Han Chuan 2 professional recycling sorting center, recycling, processing, packaging and other work. At the same time itmake will also step in the community, supermarkets and other public places set up a "paid recycling beverage cans bottles machine". By then, as long as the used waste bottles are put into the recycling machine, the amount can be added to the people's bus cards.

- Q: Are there any differences between waste plastics recycling machine and plastic granulator?

- It is suitable for the most common waste plastics, such as PP, PE, PS, regeneration of ABS, PA, PVC, PC, POM, EVA, LCP, PET, PMMA and other plastic and color mixing granulation of waste plastics recycling industry, is the most common mechanical equipment used.

- Q: How to operate a beverage bottle recycling machine?

- Which kind of bottle do you recycle, glass or plastic?

- Q: How to use the beverage bottle recycling machine?

- Plastic bottles are made of polyethylene or polypropylene and added a variety of organic solvents. Plastic bottles are widely used polyester (PET), polyethylene (PE) and polypropylene (PP) as raw materials, after adding the corresponding organic solvents,

- Q: material recycling material can do? Thank you

- We have plastic formulations and techniques that can be recommended.

- Q: What are the common types of plastic bottles and what processes are included in the PET recycling equipment?

- PET bottle recycling is divided into four parts, to obtain a clean bottle sheet, the process is: off label - crushing - Cleaning - dehydration

- Q: Isn't it because someone breaks the recycling machine or does it rarely use the recycle machine?I mean in Beijing

- Many cities are not equipped with this stuff yet

- Q: How can the old plastic bottles be recycled?

- The recovery system baffled the regular army"After solving the issue of market access, cost recovery system has made itmake such "regular army" headache.Compared with the European Union and the United States, China has always had a tradition of waste utilization because of its large population and shortage of natural resources. So, this surplus investment, using international advanced technology of waste plastic recycling and processing enterprises, and those small workshops with simple equipment to produce simple cleaning and crushing processing of raw materials competition. The "crush" simple equipment, low labor costs, low processing cost, and do not need to pay taxes and sewage treatment, will raise the price of the raw material market, but the result is only a personal profit, to the society is easy to cause two pollution and environmental harm.According to Yao Yaxiong introduction, recycled polyester chip manufacturing cost itmake the same as with foreign countries, and more than 3 times the price of raw materials recycling is abroad. If you can't get a more favorable price than the raw material manufacturer, it will be difficult to take advantage in the fierce market competition. To obtain enough high-quality raw materials, itmake then set up professional recycling system of their own, in Beijing to have yaojiayuan and Han Chuan 2 professional recycling sorting center, recycling, processing, packaging and other work. At the same time itmake will also step in the community, supermarkets and other public places set up a "paid recycling beverage cans bottles machine". By then, as long as the used waste bottles are put into the recycling machine, the amount can be added to the people's bus cards.

1. Manufacturer Overview

| Location | Jiangsu,China (Mainland) |

| Year Established | 2002 |

| Annual Output Value | |

| Main Markets | North America1.33 South America 3.32 Eastern Europe6.64 Southeast Asia 18.59 Africa 6.64 Eastern Asia 3.72 Domestic Market 59.76 |

| Company Certifications | CE;ISO9001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | |

| Export Percentage | 61% - 70% |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b) Factory Information | |

| Factory Size: | 5,000-10,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | |

Send your message to us

Plastic Retreading Equipment

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 50 Sets Per Month set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords