XPS Foamed Board Production Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 45 Sets Per Year set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications ofXPS Foamed Board Production Machine

1.width:600-1200mm

2.length:1200,1250,2450,2500mm

3.certification:CE&ISO900

Application ofXPS Foamed Board Production Machine:

Transportation: Such as steamship, aero plane, carriage, train compartment, roof Shed, case core layer, inner upholster, etc.

Architecture: Such as building wall board, decoration board, housing, office, public building interlayer, commercial decoration shelf, non-dust board, ceiling plate, etc.

Advertisement: Such as screen printing, computer lettering, ad board, etc.

Industry: Such as chemical industry antisepticising project, thermoforming, for refrigerator, for temperature keeping, for environment protection, etc.

Other applications: Such as mould plate, sports equipment, breeding equipment, seashore wet-proof facility, water-fast material, art material, various interlayer, etc.

Packaging & Delivery of XPS Foamed Board Production Machine

|

Packing Detail:1.wooden case 2.by requirements | |

| Delivery Time:70 days |

- Q: How much investment does a plastic recycling plant require for the equipment?

- Single screw extruder 6-8. Plastic crusher 1-2. Plastic sorting and cleaning. About 100 thousand of the total value.Equipment is not the most important thing to do in this industry. The following should be paid attention to:1 sources of feed back2, material sorting, identification knowledge3 plastic cleaning4 back granulation, sales direction5 environmental requirements

- Q: what equipment and how much money do you need?I Liaoning Panjin people, the existing covers an area of about 300 square meters, and now want to open a small plastic recycling materials processing plant, I do not know what equipment, how much money, what the future!!!!

- If you want to do plastic processing plants can not use such a large area, the beginning of doing not to invest too much, there is sufficient supply of goods, there are fixed customers, in expanding the scale,

- Q: How do you make a tower out of old plastic bottles?

- Compared with the European Union and the United States, China has always had a tradition of waste utilization because of its large population and shortage of natural resources. So, this surplus investment, using international advanced technology of waste plastic recycling and processing enterprises, and those small workshops with simple equipment to produce simple cleaning and crushing processing of raw materials competition. The "crush" simple equipment, low labor costs, low processing cost, and do not need to pay taxes and sewage treatment, will raise the price of the raw material market, but the result is only a personal profit, to the society is easy to cause two pollution and environmental harm. According to Yao Yaxiong introduction, recycled polyester chip manufacturing cost itmake the same as with foreign countries, and more than 3 times the price of raw materials recycling is abroad. If you can't get a more favorable price than the raw material manufacturer, it will be difficult to take advantage in the fierce market competition. To obtain enough high-quality raw materials, itmake then set up professional recycling system of their own, in Beijing to have yaojiayuan and Han Chuan 2 professional recycling sorting center, recycling, processing, packaging and other work. At the same time itmake will also step in the community, supermarkets and other public places set up a "paid recycling beverage cans bottles machine". By then, as long as the used waste bottles are put into the recycling machine, the amount can be added to the people's bus cards.

- Q: What equipment should be used for the recovery of organic waste gas in plastic flexible packaging plants?

- The organic waste gas in plastic factory can be treated by UV environmental treatment equipment, which can meet the national emission standard. The recycling process is complex, high recycling costs, but also cause two pollution. Usually solved by treatment and then by emission.

- Q: Dumpling stuffing machine plastic box under a triangular recycling 8 code and write SPS is what mean

- Plastic circular mark only 1-7 each symbol for each kind of plastic No 8 7 on behalf of the other 1 Pet cola bottles of mineral water bottles is 2 HDPE detergent cleaning agent bottle 3 is PVC pipe materials and other 4 LDPE plastic bag 5 is PP 6 PS bucket boxes and other plastic toys, disposable lunch boxes etc.

- Q: It's a package of cookies, crisps, and the like

- Food wastePlastic can not be recycled; paper can be recycled

- Q: If you buy a machine, you can start with waste foam or plastic. Ask about the production process and salesNow on the market for recycling machine particles or any foam plastic products can be processed as complete ah, made a granular product generally does not distinguish, where necessary, Shenyang has such a plant? Please tell me more about it. Thank you!

- Foam plastic granulation, what is the source of your waste materials, social waste, or the lower corner of the factory material, the transport costs of this thing is very high.

- Q: Waste plastic bottle machine was acquired after breaking it

- Look what is the bottle, the general coke bottle is PET, will be more expensive, other mineral water bottles will be cheaper, probably the acquisition of the former, the price of 3500, and the latter 2500 or so

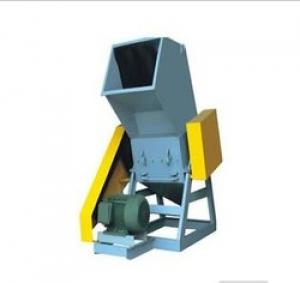

- Q: How about shredding machines for crushing recycled plastic? I'd like to make plastic particles after crushing

- Hello, shredder is an ideal equipment for comminution of refractory materials. It is perfectly possible to smash waste plastics with a shredder. We have also done a similar case of plastic crushing in paper mills.

- Q: What's the profit for a ton of plastic particles?

- Open the recycling of waste plastics processing plant investment funds generally need to be considered are: plant rent, utilities, wages, working capital, the recovery of raw materials, transportation costs is the key consideration of processing machinery and equipment (plastic recycling machine and plastic crusher), put these funds is a good investment is that you need to add up of course, the cost of capital, I need you according to the local situation, I know there is a plastic granulator price is above 30 thousand, the specific you called the * offer plastic machinery research. The profit of a ton of plastic pellets is about 3000-5000.

1. Manufacturer Overview

| Location | Shandong,China (Mainland) |

| Year Established | 2005 |

| Annual Output Value | |

| Main Markets | North America South America Eastern Europe Southeast Asia Africa Oceania Mid East Eastern Asia Western Europe |

| Company Certifications | ISO9001:2000 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b) Factory Information | |

| Factory Size: | 10,000-30,000 square meters |

| No. of Production Lines | |

| Contract Manufacturing | OEM Service Offered Design Service Offered Buyer Label Offered |

| Product Price Range | |

Send your message to us

XPS Foamed Board Production Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 45 Sets Per Year set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords