Plastic Zipper Injection Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Set m.t.

- Supply Capability:

- 20 Sets Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery Of Plastic Zipper Injection Machine

Packaging Detail: | standard export wooden cases |

Delivery Detail: | 15 Days |

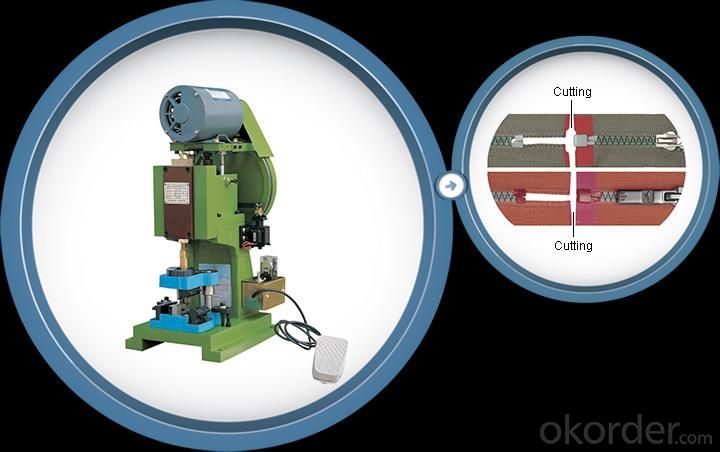

Specifications Of Plastic Zipper Injection Machine

1. Adpotscrew installation

2. Barrel lifted automatically

3. Plastic zipper injection machine

4. Adjustable conveying speed

Product Feature Of Plastic Zipper Injection MachineAdopt screw installation make the pigment melting & injecting quality evenly;

Once injection, top stop & bottom stop are made at the same time;

Auto-belt conveyor demands for less labor focre;

Hydraulic cylinders to pull strip liner in, barrel lifted automatically, humanized design and easily clean up;

User-friendly control system in English with full-scale functions;

Reliable proportional pressure valves ensures working safety;

Adjustable conveying speeds meets different requirement.

- Q: Automation has to be done at the present time when labor costs are going up sharply,

- Secondly, the performance and ease of use of the robot are evaluated. The performance of the manipulator is usually represented by its velocity and precision, speed and high speed reflected in the rapid response, the need of the implementation of components was studied, especially the cylinder and solenoid valve selection determines the performance. The repeatability is mainly reflected by the machining and assembly accuracy of the mechanical components of the manipulator.

- Q: What kinds of lubricants are used in the injection molding machine?

- Imported generally have thimble grease, the machine comes with lubricating oil bag

- Q: Production calculation... 60 / 60 seconds * / / 25 x 32 / sec / mold die =1 * 12 hours per hour yield = 12 small classInjection molding machine... Production calculation... 60 / 60 seconds * / / 25 / 32 / sec * die die =1 output * 12 hours = 12 hour shifts production 55075But I don't get enough output every day... Can only do 49501 pieces, ask 49501 pieces to take several hours to be able to do... How much extra time do I have to add to the production?... Urgent urgent... Can not take a day except what count how much time yield......

- 2. can not take a day except what count how much time yield......49501 / 1 hour yield = production hoursPS: personal experience, or to offer internal injection tube reported capacity of up to 23 hours of production capacity, 24h two classes, each class for half an hour maintenance and machine maintenance time is a must (of course sometimes less capacity of the interface). I used to be in accordance with 22h reported capacity, otherwise delivery can not come out, you hang up, give yourself more room.

- Q: What is the function of the temperature control box of the injection molding machine? Thank you

- Controlling the temperature of two heating tubes.Chasing the answerThe temperature is too high and too low, the thermostat plays the role of switch heating tube power supply.The heating tube is used to warm the mold

- Q: Just boot time, storage time 19 seconds, after running an hour, 35 seconds are stored discontent, machine storage when the storage will stop for a while, what is the reason?When the material storage machine at the start of the normal storage is full, can, after a period of time running storage storage to storage half sit motionless, then stop for a while can move, the normal storage for 19 seconds, not normal discharge time can reach two minutes, sometimes can stop to rest

- Conditions (material temperature / storage pressure, speed / storage start, stop bit, etc.) remain unchanged, respectively, measured when the boot and the hour after the storage stock rotation, to see if it slows down. If so, see if the movements are slow, or, if you check the power source. If not, the storage motor part is not normal (according to the specific type of your material storage device, for example: oil motor, motor drive)If not, the material in the cylinder is abnormal or the chemical composition of the plastic changes.If you have any questions, please feel free to ask them and hope to help you!---------------------------------------------------------------------------------------According to your supplement, the material inlet position is likely to be greater due to the possibility of thermal bridging. Look into the material in the hopper and stir the bar if necessary to see if the feed is normal. If normal, check that the barrel is cooled properly.

- Q: when the temperature rising in the exit but this is what the normal temperature increase of more than 20 degrees

- PVC for the temperature requirements are very strict, the back pressure is small, hard PVC temperature can not too low at about 170-190, too low, but not good, there is a delay melt, namely the screw does not move after injection, on the verge of opening a few seconds before time began to melt, melt after 10 seconds to stop the opening of concrete how much time delay according to the time you began to melt cooling and temperature control, there is a nozzle to just not cured so far, should not be too high. This basically can control the temperature, can be controlled within 8 degrees.

- Q: How much is the power consumption of the 80 ton injection molding machine in an hour?Plastic accessories 2 grams, the first mock exam 8, one minute can beer several times?What size of injection machine is needed for such a small fitting? 80 tons is OK?Master answer, advertising do not trouble!

- This is an estimate.Specific circumstances have changed. It might be a little lower than this. But not too much.Because the total power of the 80 ton machines is about 15 kilowatts, even if the actual use is only half, there are also 8 kilowatts.

- Q: Want to know how to play a complete product, how to calculate the pressure, speed, etc.. Example, GREE electrical appliances series 4002B chassis, how can I transfer the full product?.

- (2) debugging of die closing device;1) wipe the mold clean, then carefully and securely installed between the fixed die, and then adjust the length of the slider according to the size of the plastic block, limiting the opening of the moving template.2) adjust the ejector mechanism so that it can push the molding out of the die cavity to the preset distance.3) the clamping force should be adjusted according to the requirements of the processing technology. The die clamping force should be adjusted to the lower limit of the required clamping force.4) adjust all stroke switches to their respective positions, and adjust the closing of the die.5) adjust the speed and pressure of the mold opening and closing die, generally adjust the speed to the pre selection value, then adjust the pressure to the specified value.6) the clamping device can only work on both sides of the injection machine when the safety door is closed, and check whether the machine will stop working when the safety door is open.

- Q: What is I/O on an injection molding machine?

- I/O is the I / O address. Each device will have a dedicated I/O address, used to process the input and output information of their own if there is a conflict between the two I/O address of the device, the hardware of the system is not working properly, is computer CPU and external communication equipment for injection molding machine control.

- Q: What is low voltage protection (injection molding machine)?

- Protect the mold. Never press dies during production

Send your message to us

Plastic Zipper Injection Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Set m.t.

- Supply Capability:

- 20 Sets Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords