Injection molding machine LOG-650S8 QS Certification

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100000 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

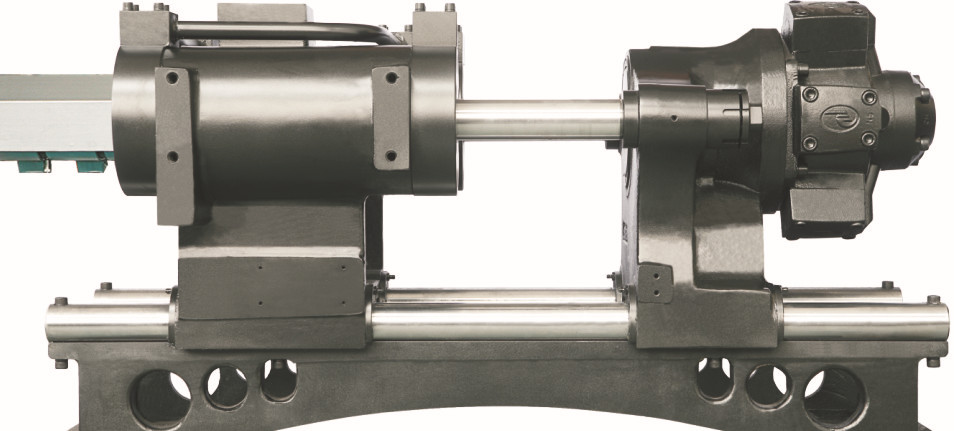

| Condition: | New | Type: | Tube Head Injection | Style: | Horizontal |

| Brand Name: | LOG | Model Number: | LOG 650S8 | Place of Origin: | Zhejiang, China (Mainland) |

| Plastic Type: | Thermoplastic | Automatic: | Yes | Injection Weight: | 2488 |

| Clamping Force: | 6500kn | Opening Stroke: | 920mm | Power(W): | 29+29kw |

| Certification: | CE | After-sales Service Provided: | Engineers available to service machinery overseas |

Packaging & Delivery

| Packaging Details: | 20GP,40GP,40HQ |

| Delivery Detail: | 30 Days |

Product performance and advantages:

1. Servo energy-saving system

Using the servo motor oil electricity composite structure

2. Servo motor high response feature

It costs only 0.05s for servo energy saving injection molding machines to achieve the maximum output, in comparison with conventional hydraulic injection molding machines. The response speed has been obviously increased, improving the production efficiency.

3. Unique function

Large colored screen with TFT interface

Full automatic close-loop control

Module design of hardware

Auto-tune PID temperature control

Pc interface USB, PIC, and FLASH…

Curve monitoring and analysis function

K-can data transmission (500Kbit/s)

On-line central monitoring function

LOG-650S8 Technical parameters

Description | Unit | LOG-650S8 | ||

international recognized models | 4640/650 | |||

injection | A | B | C | |

Tjeoretical injection volume | cm³ | 2160 | 2734 | 3376 |

Shot volume | g | 1966 | 2488 | 3072 |

Oz | 68.8 | 87.1 | 107.5 | |

Screw diameter | mm | 80 | 90 | 100 |

Injection diameter | mpa | 215 | 170 | 138 |

Screw L:D ratio | 23.6:1 | 21:1 | 19:1 | |

Scerw steoke | mm | 430 | ||

Screw rotate speed | r/min | 0-125 | ||

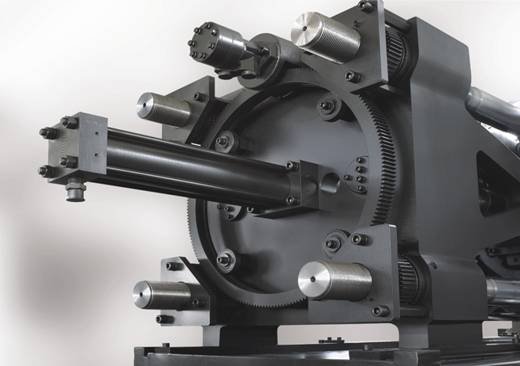

CLAMPING UNIT | ||||

Clamping force | kN | 6500 | ||

Opening stroke | mm | 920 | ||

Platen size | mm*mm | 1320*1290 | ||

Space between tie bars | mm*mm | 930*900 | ||

Maldthickness | mm | 350-910 | ||

Platen Mix stroke | mm | 1830 | ||

Ejection stroke | mm | 265 | ||

Ejcetion force | kN | 182 | ||

Power/Elcetric Heating | ||||

Hydralic system pressure | Mpa | 17.5 | ||

Pump motor | kw | 29+29 | ||

Heating power | kw | 51.6 | ||

Number of temp.conteol | 6+nozzle | |||

Other | ||||

Cycle time | sec | 6.0 | ||

Tank volume | L | 1500 | ||

Machine dimesions | m*m*m | 9.6*1.9*2.3 | ||

Weight of machine | kg | 36000 | ||

The person designing the mold chooses whether the mold uses a cold runner system or a hot runner system to carry the plastic from the injection unit to the cavities. A cold runner is a simple channel carved into the mold. The plastic that fills the cold runner cools as the part cools and is then ejected with the part as a sprue. A hot runner system is more complicated, often using cartridge heaters to keep the plastic in the runners hot as the part cools. After the part is ejected, the plastic remaining in a hot runner is injected into the next part.

- Q: What does injection pressure mean?

- Injection back pressure shall be. Refers to the injection molding machine in the plastic, the screw back a certain resistance, the end of the screw melting material to establish a certain pressure. Back pressure depends on the size of the screw structure, plastic parts quality requirements, plastic types and their characteristics. The application of back pressure should be corrected according to the characteristics of the raw material and the problems arising in the production process.

- Q: Injection molding machine clamping force appropriate, can speak a little detail, thank you

- The clamping force can be calculated, usually you buy the device, if it is not very high requirements of ordinary products would roughly calculate the clamping force, then give you the choice of models, in the production process of locking force as small as possible, the clamping force is smaller for the same exhaust, the clamping force is small mechanical wear is small, generally in the product requires locking force plus five percent can be, too no, but there is a problem can not be ignored, is the parallelism of the template, the template parallelism is good, the better to die protection, for example, he said our domestic equipment, the new machine if good process debugging, but the machine for a few years, with the clamping force of products is certainly not original, because of the great deformation of crankshaft machine is not what optimization in the template, if you in here Lock mode requirements higher, you can try some companies do box type template, the so-called box type template is a big box, hollowed out inside, the template than ordinary to thick, and the production of less deformation.

- Q: General injection molding machine agents need what conditions?

- DKM injection molding machine agent basic requirements: with injection molding machine sales experience, and has a certain after-sales maintenance capabilities

- Q: What should be noticed before the machine is stopped when the injection machine is finished?

- Dongguan City Zhen Ying Machinery equipment limited company to remind you: to prolong the life of the injection molding machine, usually must take good care of!

- Q: Process knowledge of plastic injection machine head

- The utility model has the advantages of: two face wear less, good plasticization. Disadvantages: outer wear quickly, and the barrel bore tolerances or when the debris falling into the barrel in the easy to cause the whole screw does not turn over the other is like. The apron will accelerate the cylinder bore wear. A rubber ring outer wear slower without fork and because it is not how to rotate in the pre plastic, but both ends of the surface wear, if you want to do PVC or PC and other plastic material, with the rubber ring is better, because it can avoid the dead corner so as to avoid the buildup the dark spots. Transparent injection molding products of plastic head ring: three meson screw head small overall smooth surface, in addition to the assembly part outside any one can see the front of the place can not have right angle corner, all parts should be based on the angle of smooth transition. Because the right angle corner, easy crack is not that also easy to make accumulation of materials. The material flow is not clear. For a long time to have three small yellow spots, usually is the most prone to yellowing of the site, do a lot of transparent PC.PMMA products are for three sets of design is not good, resulting in yellow.

- Q: What are the equipments around the injection molding machine?

- Commonly used are: mold temperature machine (water diversion, oil type), frozen water machine, dryer (drying equipment has centralized drying group), cold water machine, suction machine, crusher, mixer and so on

- Q: Can you tell me if there are 350 grams of three injection molding machines? How much? Thank you

- 168 tons, theoretical injection weight: A--335 grams, B--378 grams

- Q: Excuse me: what are the differences between injection molding and extrusion?

- Injection molding machine is by injecting plastic particles into the closed cavity, filled with the cavity after the suspension of work, by cooling the plastic into a certain shape, after opening the mold again. Such as plastic cups, plastic basins, plastic shells of various complicated situations and so on. He has a limited amount of injection per cycle.Extruder is through the plastic particles after the warm, through the mold continuous extrusion, such as plastic pipes, plastic plates, plastic bars and so on. It can be extruded into very long products without the limitation of cycle time.

- Q: What does "120T 140T" mean in an injection machine?

- A, an abbreviation for ounce, is a unit used by the Hongkong industry to distinguish between injection molding machines. In this way, in the domestic commonly known as "T" (ton), "12" equivalent to "160T", the screw diameter of about 32 mm. In general, the injection molding machine of various specifications, there are several specifications of the screw, buyers can choose different screw size according to their uses, the screw diameter may be selected smaller, and the groove depth is also different with a shallow depth.

- Q: Advantages and disadvantages of horizontal injection molding machines and vertical injection molding machines?

- 1. horizontal machine has the advantages of high operation, convenience, high safety performance, large bearing size and so on. The disadvantage is that the floor space is large and the price is relatively high. Suitable for medium and large moulds.2. vertical machine has the advantages of small footprint, relatively low prices, shortcomings, such as high gravity, inconvenient to take parts, etc., suitable for small molds.

Send your message to us

Injection molding machine LOG-650S8 QS Certification

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100000 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords