High Quality Injection Molding Machine LOG-90A8

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 720 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

OIL MOTOR : INTERMOT

DIRECTION VALVE: VICKERS

COMPUTER: MIRLE 9118

AC CONTACTOR : SCHNEIDER

ELECTRONIC RULER: NOVO

LUBICATION PUMP: HERG

| Model | UNIT | LOG-90A8 | |||

| International recognized model | 275/90 | ||||

| INJECTION | A | B | C | ||

| Shot volume | cm3 | 113 | 154 | 181 | |

| Injection | Shot weight | g | 106 | 144 | 170 |

| volume | |||||

| ps | Oz | 3.7 | 5.1 | 5.9 | |

| Screw diameter | mm | 30 | 35 | 38 | |

| Injection pressure | mpa | 243 | 179 | 152 | |

| Screw L:D ratio | 20:01 | 20:01 | 18:01 | ||

| Screw stroke | mm | 160 | |||

| Screw rotate speed | r/min | 0-180 | |||

| Clamping force | kn | 900 | |||

| Opening stroke | mm | 320 | |||

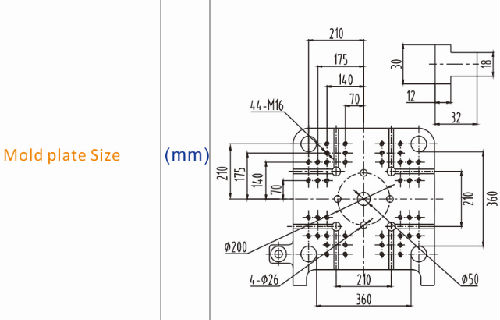

| Platen size | mm*mm | 540*540 | |||

| Space between tie bars | mm*mm | 360*360 | |||

| Mold thickness | mm | 150-360 | |||

| Platen Max stroke | mm | 680 | |||

| Ejection stroke | mm | 100 | |||

| Ejection force | kn | 31 | |||

| Hydraulic system pressure | mpa | 16 | |||

| Pump motor | kw | 9 | |||

| Heating power | kw | 6.5 | |||

| Number of temp.control | 3+射嘴(nozzle) | ||||

| Cycle time | sec | 1.1 | |||

| Oil tank capacity | L | 160 | |||

| Machine dimensions | m*m*m | 4.2*1.1*1.7 | |||

Products performance and advantages

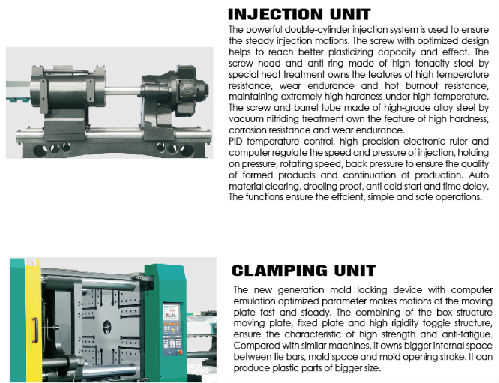

1,Clamping parts

The new generation mold locking device and computer emulation optimized parameter makes motions of the moving plate,fixed plate and high rigidity toggle structure,the characteristic of high strength and anti-fatigue is secured.As compared with similar machines,it owns bigger internal spur between tie bars,mold space and mold opening stroke and may process plastic products of bigger size.

2,Computer controller

Professional injection moulding machine controller with software and hardware of industrial standard is convenient to expansion and revision of performance.

Adopting double CPU control makes high speed.

Mainly adopting PID control,the control accuracy reaches±1°.

Has the function of network management,improving efficency.

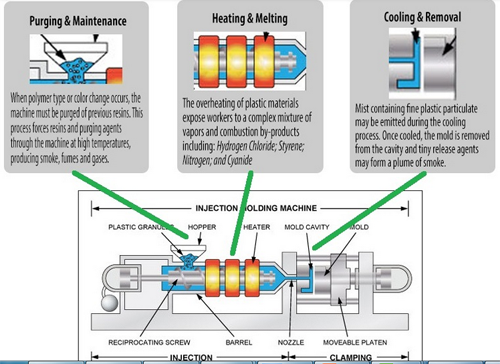

3,The injection unit

Short and forceful double-cylinder injection system is used to ensure the steady injection motion.The strain free fixed mold plate and screw assembly with optimized design help to reach better plasticing capacity and effect.PID temperature control regulate the speed and pressure of injection,pressure keeping,smelting,back pressure and other motions to ensure the quality of formed products and continuation of production.Auto material preparation,drooling proof,and anti cold start lapse functions ensure the high efficent,simple and safe operations.

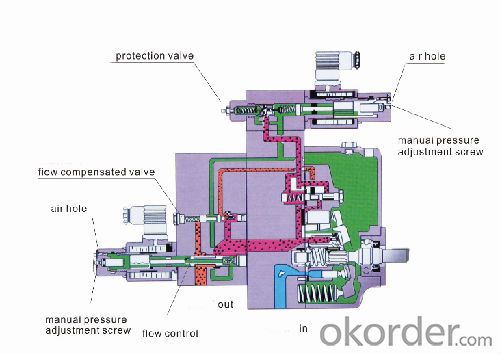

4,The hydraulic unit

High efficiency,energy-saving and high precise proportional pressure and flow variable displacement pump system make the out of the hydraulic system matching the required power for entire machine operation without loss of high pressure throttle and overflow energy.As comparedwith constant displacement pump,it saves power by 30%~60%.A motor with same power may be fitted with an oil pump of bigger displacement and thus accelerates the speed of machine.Besides,the low oil temperature will prolong the service life of sealing elements.

Buffer device is used in every mold opening and clamping oil way to ensure steady mold opening and clamping operation without any impact.Besides,differential mold clamping operation is fitted to ensure high production efficiency.

5,The mould adjusting unit

The automatic mold adjusting device driven by hydraulic motor adopts gear coupling drive,features steadiness,speedinees,high-efficiency and saving mold loading time.

Common thermoplastic resins include:

Polyethylene PE

Polyvinyl Chloride PVC

Polypropylene PP

Polystyrene PS

Polyethlene Terephthalate PET

Acrylonitrile-butadiene-styrene ABS

Styrene-Acrylonitrile SA

Acrylic PMMA

Polyamide PA (Nylon)

Styrene-Acrylonitrile SAN

Polycarbonate PC

Products performance and advantages

1,Clamping parts

The new generation mold locking device and computer emulation optimized parameter makes motions of the moving plate,fixed plate and high rigidity toggle structure,the characteristic of high strength and anti-fatigue is secured.As compared with similar machines,it owns bigger internal spur between tie bars,mold space and mold opening stroke and may process plastic products of bigger size.

2,Computer controller

Professional injection moulding machine controller with software and hardware of industrial standard is convenient to expansion and revision of performance.

Adopting double CPU control makes high speed.

Mainly adopting PID control,the control accuracy reaches±1°.

Has the function of network management,improving efficency.

3,The injection unit

Short and forceful double-cylinder injection system is used to ensure the steady injection motion.The strain free fixed mold plate and screw assembly with optimized design help to reach better plasticing capacity and effect.PID temperature control regulate the speed and pressure of injection,pressure keeping,smelting,back pressure and other motions to ensure the quality of formed products and continuation of production.Auto material preparation,drooling proof,and anti cold start lapse functions ensure the high efficent,simple and safe operations.

4,The hydraulic unit

High efficiency,energy-saving and high precise proportional pressure and flow variable displacement pump system make the out of the hydraulic system matching the required power for entire machine operation without loss of high pressure throttle and overflow energy.As comparedwith constant displacement pump,it saves power by 30%~60%.A motor with same power may be fitted with an oil pump of bigger displacement and thus accelerates the speed of machine.Besides,the low oil temperature will prolong the service life of sealing elements.

Buffer device is used in every mold opening and clamping oil way to ensure steady mold opening and clamping operation without any impact.Besides,differential mold clamping operation is fitted to ensure high production efficiency.

5,The mould adjusting unit

The automatic mold adjusting device driven by hydraulic motor adopts gear coupling drive,features steadiness,speedinees,high-efficiency and saving mold loading time.

Clamping system: Faster response, stable and high rigidity

Injection system: Accurate and flexible, lower rejection rate

Control system: Computer and simple operation,molding data memory system

Power system: Energy saving, high efficient and precise

Metal parts: The thickness of our frame, metal plate and wallboard are thicker than other company.

Other Information

Ceramic heating loop: Uniform heating, better thermal insulation properties so good for production

Visiable lubrication system: on time clean, avoid cast steel parts abrasion and broken.

Oil treasure: Filter of hydraulic oil,good for pump and valves

Long working life: Imported spare parts and updated version

Aftersales service: Professional & timely

Injection molding machines can fasten the molds in either a horizontal or vertical position. The majority of machines are horizontally oriented, but vertical machines are used in some niche applications such as insert molding, allowing the machine to take advantage of gravity. Some vertical machines also don't require the mold to be fastened. There are many ways to fasten the tools to the platens, the most common being manual clamps (both halves are bolted to the platens); however hydraulic clamps (chocks are used to hold the tool in place) and magnetic clamps are also used. The magnetic and hydraulic clamps are used where fast tool changes are required.

The person designing the mold chooses whether the mold uses a cold runner system or a hot runner system to carry the plastic from the injection unit to the cavities. A cold runner is a simple channel carved into the mold. The plastic that fills the cold runner cools as the part cools and is then ejected with the part as a sprue. A hot runner system is more complicated, often using cartridge heaters to keep the plastic in the runners hot as the part cools. After the part is ejected, the plastic remaining in a hot runner is injected into the next part.

- Q: How will the screw speed of injection molding machine be adjusted slowly?

- In the screw speed adjustment, from the lower speed start, gradually commissioning to higher speed, and then determine the screw speed.The working speed of the screw of the injection machine is unstable and is affected by the following factors:1, drive V belt wear seriously, slipping when working.2, V belt drive belt wheel center distance is too small, so that belt drive can not and belt pulley trapezoidal slope correct friction drive work.3. The temperature of the heating material in the barrel is low, and the material is not uniform, which leads to the screw rotation of the injection machine, the increase of the working load torque, and the instability of the screw speed of the injection molding machine.4, injection molding machine screw thrust bearing damage, etc..

- Q: What are the main parts of an injection molding machine?

- (1) the function of injection system in injection molding system: injection system is one of the most important parts of injection molding machine. There are 3 main forms, plunger type, screw type, screw type, pre plastic plunger and injection type. Screw type is the most widely used at present. It is, in a circular plastic injection machine, within a specified time will be a certain number of plastic heating plasticization, pressure and velocity in the screw, through the molten plastic is injected into the mold cavity. At the end of the injection, the melt is injected into the mold cavity to retain the shape. Injection system: injection system consists of plasticizing device and power transmission device. The plasticizing device of screw type injection molding machine is mainly composed of feeding device, material barrel, screw rod and nozzle. The power transmission device includes an injection cylinder, an injection seat, a moving cylinder, and a screw drive device (a melt motor). (2) the function of the die closing system: the function of the die closing system is to ensure the die closing, opening and ejection. At the same time, in the mold closed, to give the mold enough clamping force, in order to resist the molten plastic into the mold cavity cavity pressure, to prevent the mold slit, resulting in the bad situation of the product. The die making system consists of a die clamping device, a die adjusting mechanism, an ejector mechanism, a front and rear clamping plate, a moving die plate, a die cylinder and a safety protection mechanism.

- Q: How to reset the EM-120 origin of the injection machine?

- 6, locking machine to machine hinge straight;7, repeat third steps;8, enter 1 at the default mode 1; move the cursor back to preset 1; appear as input Press confirm again;9, enter 2000 at the preset mode 2;10, repeat the lock die 3 to 4 times to the machine hinge straight, see the actual value of the lock more than how many; 2000 minus the remaining numberValue; enter preset 2;11, reset the high pressure die termination position and adjust the clamping force to the die.

- Q: General injection molding machine agents need what conditions?

- This is to ask manufacturers, each manufacturer of different

- Q: How to repair the injection machine?

- Common faults in the use of injection molding machines and solutions are as follows:Part 1: Problems and treatment methods of mould locking parts:(1) not locking dies:Handling method: 1) check the front travel switch of safety door and repair it.2) check the 24V5A power in the electric box, replace the insurance and the power box.3): check whether the spool is stuck, cleaning the spool.4): check whether the output of the I/O board, the solenoid valve is charged.5): check whether the hydraulic safety switch is closed, whether the mechanical lock rod is opened or not.(two) the opening and closing of the die machine:Handling method: 1) check whether the lubricating oil pipe is broken or, if so, reconnect the tubing.2): small amount of lubricating oil, lubricating oil amount increase, 50 die once or manually add oil and lubricating oil.3): clamping force, check whether the mold needs large clamping force, lower the clamping force.4): the current fluctuation of the amplifier board, check whether the current parameters meet the acceptance criteria, re adjust the current value.5): parallelism error indicator check head board parallelism is greater than the acceptance criteria; adjust the parallelism.

- Q: Introduction of injection molding machine

- Introduction of YX - ZR injection molding machine on the internet:The leading products of the company are YX-ZR series single stage capacity increasing injection molding machines and their injection products. The core technology of super large single step type compatibilizing injection molding machine developed by key institutions with independent intellectual property rights, breaks through the traditional structure design of injection molding machine limitations, and consumption premise are significantly reduced in weight and energy, realize the large capacity injection, the production of large injection molding is possible.Application of injection moulding machine (example of producing products)(1) all injection trays (silo, backing plate);(two) full injection moulding of building formwork and waterproof partition of concrete building;(three) full injection molding and assembling ton box;(four) full injection, hot melt and electric melting large pipe fittings;(five) full injection, boat body, furniture and earthquake activity room;(six) full injection molding isolating piers for road safety.YX-ZR series single step type compatibilizing injection molding machine due to the single step type compatibilizing injection and wedge locking system, the screw and the international advance injection, two-stage or multi-stage compatibilizing injection combined with traditional injection molding machine toggle clamping system has its advantages compared to Aaron than:First, the weight of the whole machine is reduced by more than 50% compared with the traditional machine, and the manufacturing cost of the equipment is fundamentally reduced;

- Q: We are going to an injection molding machine factory at once. I don't know yet which is what I learn, NC, please master, and hope to be able to put the knowledge about injection molding machine told me, I appreciate the injection molding machine is that NC programming ah | please master, thank you

- Do you mean the factory that produces injection molding machines or the injection molding machine that uses injection molding machines? Injection molding machine with numerical control is very different, the use of injection molding machine injection molding machine factory programming basically no debugging, the injection molding conditions, such as injection temperature, velocity and pressure; relatively low technology content; if you go to the production of injection molding machine factory, should be used to control knowledge, such as a lot of injection molding machine the parts are manufactured by CNC machine tool.

- Q: Commissioning process of injection molding machine

- When we receive a set of moulds, we need to choose the machine according to the size of the mold, the clamping force and the size of the glue.Determine the type of machine before you enter the real tune. (the premise is that the machine is normal.)1. we first beer 10 beer water board plastic pieces (not go together -- about 95% of the full plastic glue), set the appropriate pressure to ensure that the actual pressure below the set (high pressure), starting from the highest rate of 99%, and then gradually reduce an amount equal to (10%) 10 plastic beer beer. - (constant pressure, rate of change of each separated by 10% to complete the 10 beer beer).2. record the filling time of each beer and the injection peak pressure.

- Q: Not transformer. It's wires and meters. Because the transformer is public. If 10 kilowatts is not enough. How much is enough?

- 160T injection molding machine, if you want to use electromagnetic heating control panels for energy-saving transformation, the easiest way is to determine the original electric heating block is a few areas? What is the power of each zone? Then, in accordance with this to match the line, a few zones with several electromagnetic heating control panels, the power of each board and the power of the same heat block, or close to the line. In this way, the power saving rate can reach more than 40%, and the production efficiency can also be improved by about 20%. The friend in need can find Xin Rui energy saving manager, consult the order, and have professional technical guidance!

- Q: How to install filter screen for injection machine nozzle?

- There are special filter nozzle, used for recycling materials, can protect the mold and hot runner, with few manufacturers.

Send your message to us

High Quality Injection Molding Machine LOG-90A8

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 720 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords