Injection Molding Machine LOG-500A8 QS Certification

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 720 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Condition: New

Type: Preform Injection

Style: Horizontal

Brand Name: LOG

Model Number: LOG-500A8

Place of Origin: Zhejiang, China (Mainland)

Plastic Type: Thermoplastic

Automatic: Yes

Injection Weight: 1919g

Injection Rate: <SPAN class=attr-value title=459cm3/s style="BORDER-RIGHT: 0px; PADDING-RIGHT: 0px; BORDER-TOP: 0px; PADDING-LEFT: 0px; PADDING-BOTTOM: 0px; MARGIN: 0px; VERTICAL-ALIGN: baseline; BORDER-LEFT: 0px; PADDING-TOP: 0px; BORDER-BOTTOM: 0px; FONT-FAMILY: inherit; WORD-WRAP: break-word; font-stretch: inherit">459cm3/s

Clamping Force: 5000KN

Opening Stroke: 780mm

After-sales Service Provided: Overseas third-party support available

energy saving: oil saving

| Description | Unit | LOG-500A8 | ||

| international recognized models | 3240/500 | |||

| Injection | A | B | C | |

| Tjeoretical injection volume | cm³ | 1590 | 2040 | 2550 |

| Shot volume | g | 1494 | 1919 | 2397 |

| Oz | 52.3 | 67.2 | 83.9 | |

| Screw diameter | mm | 75 | 85 | 95 |

| Injection diameter | mpa | 204 | 159 | 127 |

| Screw L:D ratio | 23.8:1 | 21:01 | 18.7:1 | |

| Scerw steoke | mm | 360 | ||

| Screw rotate speed | r/min | 0-150 | ||

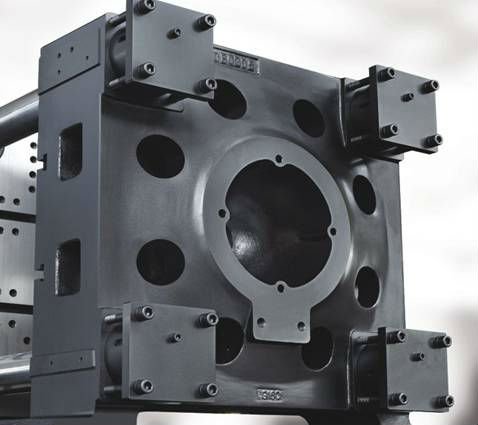

| CLAMPING UNIT | ||||

| Clamping force | kN | 5000 | ||

| Opening stroke | mm | 820 | ||

| Platen size | mm*mm | 1180*1180 | ||

| Space between tie bars | mm*mm | 830*830 | ||

| Maldthickness | mm | 300-820 | ||

| Platen Mix stroke | mm | 1600 | ||

| Ejection stroke | mm | 210 | ||

| Ejcetion force | kN | 111 | ||

| Power/Elcetric Heating | ||||

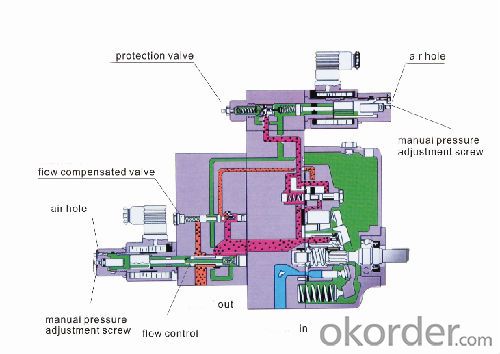

| Hydralic system pressure | Mpa | 17.5 | ||

| Pump motor | kw | 18.7+29 | ||

| Heating power | kw | 42.5 | ||

| Number of temp.conteol | 5+nozzle | |||

| Other | ||||

| Cycle time | sec | 5.2 | ||

| Tank volume | L | 1150 | ||

| Machine dimesions | m*m*m | 9.2*1.85*2.41 | ||

| Weight of machine | kg | 22000 | ||

Packaging & Delivery

| Packaging Details: | one machine in a 40GP container |

|---|---|

| Delivery Detail: | a week if it's at stock OR a month |

Specifications

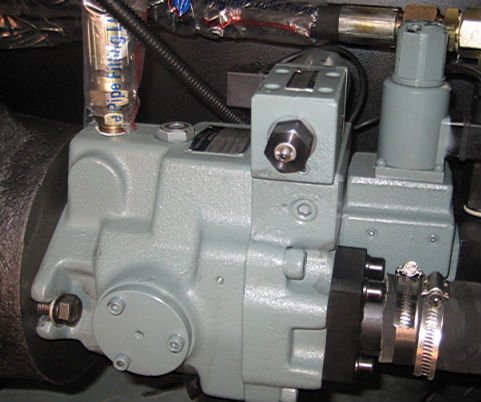

high response 2. high precise 3. oil saving 4. water saving 5. long working life

- Q: Can carbon fiber be used for injection molding?

- Carbon fiber can be used for injection molding, and the typical product is CF+PPS. Carbon fibers are difficult to process two times, such as drilling on molded products, plain drills, drilling holes, and drilling bits. Therefore, in the part design to avoid two machining. In addition, as with plastic and glass fiber, and carbon fiber after the screw injection molding machine screw wear increases, the life expectancy was shortened. Global carbon fiber technology and production are still largely in the hands of Japan and the United states. There are less than 20 countries and regions that can realize the industrialization of carbon fiber in the world. There are no more than 12 large-scale production enterprises. Dongli, Japan, the United States and Japan's Toho Zoltek Japan MITSUBISHI rayon is global carbon fiber production capacity of the top four manufacturers, which accounted for four of the total global carbon fiber capacity 23.4%, 17.1%, 14.3% and 10.3%, and China enterprises accounted for only 4.3%. The global carbon fiber production is mainly based on PAN based carbon fiber. In 2009, PAN based carbon fiber production capacity accounted for about 96% of the total carbon fiber production capacity of the world. The concrete application of carbon fiber shows that "the structure of electronic products, the characteristics of materials and the method of their selection" (people's Posts and Telecommunications Press, 2010.4)

- Q: What measures can be taken to shorten the molding process cycle of injection molding machines?

- Reduce the mold temperature, reduce the heating temperature of cylinder, increase the speed of die closing and shorten the cooling and holding time.

- Q: Every time the adhesive is stable, the glue is basically stable, but about 100 of the 2-3 die will not be in place, for example, the 50MM will stop

- Whether the travel switch is in bad contact or that the sealing ring and the wear resistant hydraulic oil are used for a long time and need to be replaced

- Q: How to reset the EM-120 origin of the injection machine?

- Setting method:1, the high pressure die termination position is set to 0 P2, mold opening to the end;3, press cancel + high voltage lock mode, 3 seconds appear origin setting screen;4, enter 9999 at the preset mode 1; move the cursor back to the preset 1; enter a question mark by the input; Press confirm again;5, press the button manually. Ejection of products; about 10MM after mold adjustment;

- Q: What is a vertical injection molding machine?

- Vertical injection molding machine:1 、 vertical non column lock mold, horizontal injection molding, mold three sides open, more convenient and safe operation.2 、 injection pressure, torque hydraulic motor control, large spiral torque, high pre plastic, the system pressure by the proportional valve control.3, multi section pressure output, pressure sensitive, accurate and accurate.4 、 can install single, double slide, turntable system to improve production efficiency.5, suitable for the production of large doses of brain glue.

- Q: How can the injection machine be set with parameters?

- 4. check the cooling pipe for long distance flow, and the oil cooler and barrel end of the cooling water jacket into the cooling water.5. before the injection machine operation, check whether there is lubrication in each moving part, and add enough lubricating oil.6. turn on the heater and heat the barrel. When the temperature of each section meets the requirements, the insulation will be kept warm for a period of time to keep the machine temperature stable. Holding time varies according to the requirements of different equipment and plastic raw materials.7. add enough plastic to the hopper. According to the injection of different plastic requirements, some of the raw material is best to go through drying.8., the heat insulation cover on the cylinder can be covered, so that the electric energy can be saved, and the service life of the electric heating coil and the current contactor can be prolonged.Operation process1., not for convenience, and arbitrarily cancel the role of security doors.2. pay attention to observe the temperature of the pressure oil, the oil temperature should not exceed the prescribed range. The ideal working temperature of hydraulic oil should be kept between 45-50 degrees centigrade, which is suitable for the range of 35-60 centigrade.3. attention to adjust the travel switch, to avoid the machine in the action of impact.End-of-job1. after the injection molding machine operation is completed, the cylinder should be cleaned of plastic, to prevent residual oxidation or long-term thermal decomposition.2. should be open to the mold, the toggle mechanism is in the locked condition of time.3. workshop must be equipped with lifting equipment. When handling dies, care shall be taken to ensure safety in production.

- Q: Large injection molding machine to block reuse

- This piece of material called die materials, is one of the raw materials for the production of renewable materials, first with a chainsaw broken down into small pieces, cut into particles in the melt drawing, or put small smash directly, really help you look forward to adopt,

- Q: What do you mean by the "starting position and time" of the injection molding machine?.

- When injection is converted to holding pressure, it is determined by time or position. If the location, the general set pressure holding position is about 5% of the storage position.

- Q: when the temperature rising in the exit but this is what the normal temperature increase of more than 20 degrees

- 1, back pressure regulation is too large; 2, screw idle or slip, cause melt time longer, friction produce heat; 3, setting temperature is too low, melt resistance is too large, friction produce heat.Injection molding machine: injection molding machine, also known as injection molding machine or injection machine. It is a thermoplastic or thermosetting plastic plastic molding mold made of plastic products of all shapes of the main molding equipment. The injection molding machine heats the plastic, applying high pressure to the molten plastic to make it crack and fill the mold cavity. According to the arrangement of injection device and mould locking device, they can be divided into vertical type, horizontal type and vertical horizontal compound type.

- Q: Can you tell me if there are 350 grams of three injection molding machines? How much? Thank you

- I don't know this brand of LG, Jin Haitian I know!

Send your message to us

Injection Molding Machine LOG-500A8 QS Certification

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 720 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords