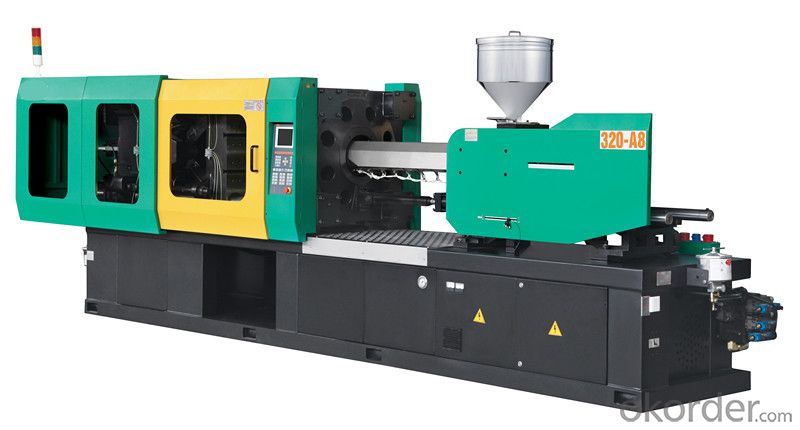

Injection Molding Machine LOG-320A8 QS Certification

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 720 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

| Quick Details | |

| Condition: New | Place of Origin: China (Mainland) |

| Type: Tube Head Injection | Plastic Type: Thermoplastic |

| Style: Horizontal | Automatic: Yes |

| Brand Name: LOG | Injection Weight: 1120g |

| Model Number: LOG-320A8 | Clamping Force: 3200KN |

| Opening Stroke: 615mm |

Packaging & Delivery

| Packaging Details: | one machine in a 40 GP container |

|---|---|

| Delivery Detail: | a week if it's at stock OR a month |

Specifications

1.high response 2. high precise 3.oil saving 4. water saving 5. long warking life

Details :

LOG-320A8 | ||||

International size rating | 1870/320 | |||

INJECTION | A | B | C | |

Shot volume | cm3 | 1062 | 1231 | 1414 |

Shot weight | G | 966 | 1120 | 1286 |

OZ | 33.7 | 39.2 | 44.9 | |

Screw diameter | mm | 66 | 70 | 75 |

Injection pressure | mpa | 175 | 152 | 133 |

Screw L:D ration | 21:1 | 21:1 | 19.6:1 | |

Screw stroke | mm | 320 | ||

Screw speed(stepless) | r/min | 0-150 | ||

CLAMPING UNIT | ||||

Clamping force | kn | 3200 | ||

Opening stroke | mm | 615 | ||

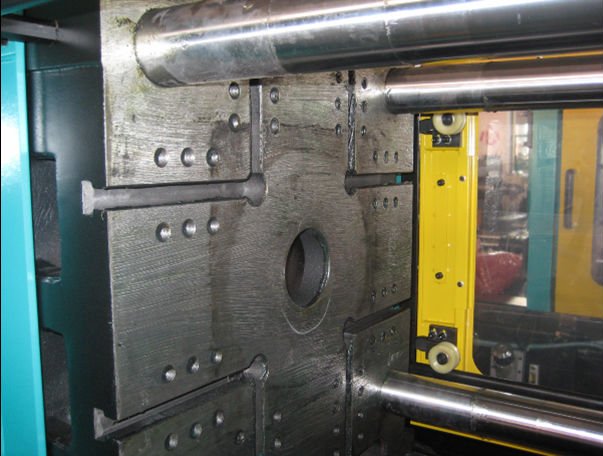

Platen size | mm×mm | 945×945 | ||

Space between fie bars | mm×mm | 660×660 | ||

Mold fhickness(Min-Max) | mm | 250-670 | ||

Max.daylingt | mm | 1285 | ||

Hydraulic ejection stroke | mm | 160 | ||

Hydraulic ejection force | kn | 77 | ||

POWER UNIT | ||||

Hydraulic system pressure | mpa | 17.5 | ||

Pump motor | kw | 30 | ||

Heating capacity | kw | 21.5 | ||

Number of femp confrol zones | \ | 5+ nozzle | ||

GENERRL | ||||

Dry-cycle fime | Sec | 5.0 | ||

Oil fank capacify | λ | 500 | ||

Machine dimensions | m×m×m | 8.6×1.58×2.25 | ||

Machine weight | kg | 13000 | ||

1.template structure of the high-rigidity design,with a bigger clamiping unit. 2. T- slots and conventional screw holes make mold is easy to install. 3 by using our patent bridge structure ,the injection unit will be more stable 4, equipped with imported low-noise and high efficiency variable pump system,saving energy 30% to 60% and and 20 %~40% oil and water 5. high-efficiency filter makes the hydraulic oil clean and a long working life 6. the color screen control system, is conventional to operate it.

- Q: Injection molding machine products have cloak how to solve?

- Or choose something less liquidIf it can not solve the need to start from the mold block, the mold is not high precision, then how to change the material is very resolved

- Q: What is an injection molding machine?

- Injection molding machine, also known as injection molding machine or injection machine. It is a thermoplastic or thermosetting plastic plastic molding mold made of plastic products of all shapes of the main molding equipment.Working principle:The working principle of injection molding machine and injection syringe with similar, it is the use of screw (or piston) thrust, the plasticizing good molten state (i.e. viscous flow) plastic injected into the mold cavity closed good after curing stereotypesmade the process of the products. Injection molding is a cycle process, each cycle mainly include: quantitative feeding - melt plasticization - pressure, injection - filling mold cooling - die opening pieces. Take out the plastic parts and then close the die for the next cycle.

- Q: Pick up a living requirements for luminaires for PVC, never used the material that this material is not good to ask you to the point of transparency is not a lamp, because it will shine requirement.

- 1, plastic processingAfter 24 hours at room temperature, the water absorption is less than 0.02%, so no drying is necessary. If it must be dry, it can be put into the hot stove of 60-70 DEG C for 3 hours or 80 hours at the drier for 1-1.5 hours.Recycled materials can be used up to 20% and new materials, the amount of recycled materials depends on the end use of the product. Misuse of recycled materials can make injection failure, not only the recycling of too many components, more because the material after repeated processing. More recycled materials, more quality drop.2 、 selection of injection molding machineUPVC because of its high viscosity and easy decomposition, the decomposition product has a corrosive effect on iron, and its injection molding must be made of special plasticizing parts and temperature control system.Ramada in the product coverage of each kind of clamping force model, has a special UPVC injection system, and in accordance with the UPVC pipe products core pulling requirements, with special security door device. Under normal circumstances, as long as the injection volume can meet the weight requirements, the use of this series of UPVC injection molding device can be molded into high-quality products.

- Q: how fast preheating ah, the more detailed the better, do not understand, please do not answer, online, etc.

- Do not know you have no injection molding machine mold with mold temperature machine temperature control, if any, can do a coil in the fuel tank heat exchanger from the mold temperature machine connected to a set of loop heat exchange in a can to the mailbox.

- Q: What's the injection?

- Is the plastic products processing, the use of mold a molding

- Q: How to repair the injection machine?

- Common faults in the use of injection molding machines and solutions are as follows:Part 1: Problems and treatment methods of mould locking parts:(1) not locking dies:Handling method: 1) check the front travel switch of safety door and repair it.2) check the 24V5A power in the electric box, replace the insurance and the power box.3): check whether the spool is stuck, cleaning the spool.4): check whether the output of the I/O board, the solenoid valve is charged.5): check whether the hydraulic safety switch is closed, whether the mechanical lock rod is opened or not.(two) the opening and closing of the die machine:Handling method: 1) check whether the lubricating oil pipe is broken or, if so, reconnect the tubing.2): small amount of lubricating oil, lubricating oil amount increase, 50 die once or manually add oil and lubricating oil.3): clamping force, check whether the mold needs large clamping force, lower the clamping force.4): the current fluctuation of the amplifier board, check whether the current parameters meet the acceptance criteria, re adjust the current value.5): parallelism error indicator check head board parallelism is greater than the acceptance criteria; adjust the parallelism.

- Q: We are going to an injection molding machine factory at once. I don't know yet which is what I learn, NC, please master, and hope to be able to put the knowledge about injection molding machine told me, I appreciate the injection molding machine is that NC programming ah | please master, thank you

- Injection molding machine can not be programmed, mainly the use of operations, adjustment, parameter settings, etc.

- Q: Injection molding machine maintenance Daquan books catalog

- Chapter 1 Principle and structure of injection molding machineSection 1 basic components of injection moulding machineSecond, the working principle of injection molding machineThe third section of the injection molding machine classification and the corresponding structureFourth section of injection molding machine technical parameterFifth section of the mechanical transmission system of injection molding machineInjection system of plunger type injection molding machineTwo 、 injection system of reciprocating injection molding machineThree 、 mould locking system of injection molding machineSixth section hydraulic transmission system of injection molding machineSeventh section electric control system of injection molding machineThe second chapter is the maintenance foundation of injection molding machineSection 1 basic principle of hydraulic driveI. brief introduction of hydraulic transmission systemTwo. The theoretical basis of hydraulic transmissionThree. Components and graphic symbols of hydraulic transmission systemFour 、 hydraulic circuit diagram readingSecond sections of electrical basisI. graphical symbols used in injection molding machines for electronic componentsTwo, the structure and function of common electronic componentsThree 、 reading of circuit diagramFour 、 common marking symbols of injection machine operating panel

- Q: For example, according to the shape, the injection quantity, clamping force, and electric, all electric ^^^ hope to get a more comprehensive answer Thank you!!!

- Shape can be divided into: horizontal, verticalInjection molding, then small to the product weight, 1G large to a few kilograms have, quite a lot.Because now the injection molding machine manufacturers are based on customer demand to do injection molding machine configuration, such as the general 180T clamping force of the frame, with 36-38mm screw, now the same rack can be the smallest 20mm screw. Should say, as long as you ask what kind of can match what kind of, so that the injection molding, mold force is now not necessarily, according to your product requirements to configure!

- Q: Recommend durable low pressure injection molding machines?

- Low pressure injection molding machine is mainly used in the encapsulation and protection of precise and sensitive electronic components. Low pressure injection molding process is the injection pressure uses a very small (0 ~ 6MPa) package material is injected into the mold and rapid curing (5 to 50 seconds) of the packaging process, so that products meet the insulation, temperature resistance, impact resistance, vibration, moisture-proof, waterproof, dustproof, chemical corrosion and so on performance. It is widely used in many fields, including: printed circuit board (PCB), automotive electronics, automotive wiring harness, automotive connectors, sensors, micro switch etc..

Send your message to us

Injection Molding Machine LOG-320A8 QS Certification

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 720 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords