Injection molding machine LOG-320S8/A8 QS Certification

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100000 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Condition: | New | Type: | Tube Head Injection | Style: | Horizontal |

| Brand Name: | LOG | Model Number: | LOG-320S8 | Place of Origin: | Zhejiang, China (Mainland) |

| Plastic Type: | Thermoplastic | Automatic: | Yes | Injection Weight: | 1120g |

| Injection Rate: | >362cm3/s |

| Clamping Force: | 3200KN | Opening Stroke: | 615mm | ||

| Power(W): | 31kw | Certification: | CE | After-sales Service Provided: | Engineers available to service machinery overseas |

| blue: | yellow |

Packaging & Delivery

| Packaging Details: | 20GP,40GP,40HQ |

| Delivery Detail: | 30 days |

Product Description

Product performance and advantages:

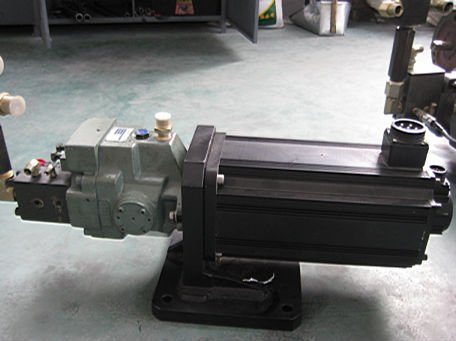

1. Servo energy-saving system

Using the servo motor oil electricity composite structure

2. Servo motor high response feature

It costs only 0.05s for servo energy saving injection molding machines to achieve the maximum output, in comparison with conventional hydraulic injection molding machines. The response speed has been obviously increased, improving the production efficiency.

3. Unique function

Large colored screen with TFT interface

Full automatic close-loop control

Module design of hardware

Auto-tune PID temperature control

Pc interface USB, PIC, and FLASH…

Curve monitoring and analysis function

K-can data transmission (500Kbit/s)

On-line central monitoring function

LOG-320S8 Technical parameters

Description | Unit | LOG-320S8 | ||

international recognized models | 1870/320 | |||

injection | A | B | C | |

Tjeoretical injection volume | cm³ | 1062 | 1231 | 1414 |

Shot volume | g | 966 | 1120 | 1286 |

Oz | 33.7 | 39.2 | 44.9 | |

Screw diameter | mm | 65 | 70 | 75 |

Injection diameter | mpa | 175 | 152 | 133 |

Screw L:D ratio | 22.6:1 | 21:1 | 19.6:1 | |

Scerw steoke | mm | 320 | ||

Screw rotate speed | r/min | 0-150 | ||

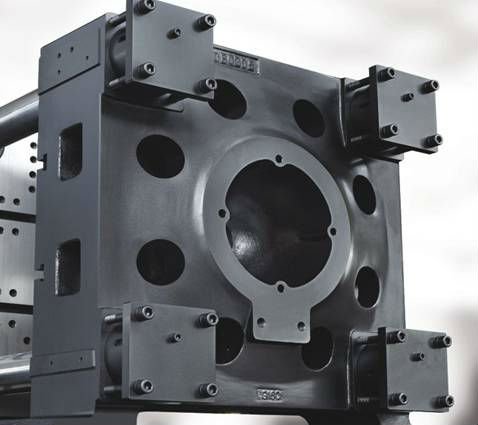

CLAMPING UNIT | ||||

Clamping force | kN | 3200 | ||

Opening stroke | mm | 615 | ||

Platen size | mm*mm | 945*945 | ||

Space between tie bars | mm*mm | 660*660 | ||

Maldthickness | mm | 250-670 | ||

Platen Mix stroke | mm | 1285 | ||

Ejection stroke | mm | 160 | ||

Ejcetion force | kN | 77 | ||

Power/Elcetric Heating | ||||

Hydralic system pressure | Mpa | 17.5 | ||

Pump motor | kw | 31 | ||

Heating power | kw | 25.3 | ||

Number of temp.conteol | 5+nozzle | |||

Other | ||||

Cycle time | sec | 5.0 | ||

Tank volume | L | 500 | ||

Machine dimesions | m*m*m | 6.8*1.63*2.25 | ||

Weight of machine | kg | 13000 | ||

- Q:Haitian injection molding machine alarm, hydraulic insurance exception, what are the reasons?

- Injection molding machine: injection molding machine, also known as injection molding machine or injection machine. It is a thermoplastic or thermosetting plastic plastic molding mold made of plastic products of all shapes of the main molding equipment. The injection molding machine heats the plastic, applying high pressure to the molten plastic to make it crack and fill the mold cavity. According to the arrangement of injection device and mould locking device, they can be divided into vertical type, horizontal type and vertical horizontal compound type. The injection molding machine has the ability of a complex shape, size precision or with plastic metal inserts texture dense, is widely used in national defense, electronics, automotive, transportation, building materials, packaging, agriculture, education, health and daily life in various fields. In today's rapid development of plastic industry, plastic injection molding machine plays an important role both in quantity or variety, the total production of the plastic molding equipment 20%--30%, thus becoming the fastest growth in plastics machinery, one of the largest number of production model.

- Q:How to calculate the capacity of mold injection molding?

- The counter machine with opening times ah, before you boot reset, see how much time and work mode, then take out the number of the first mock exam will be able to come out of the number of products, and then go to work for a long time to know how much time ah

- Q:Does the injection machine have to use cooling water?

- First, the injection molding machine normally work, it is necessary to cooling water.Two. Cooling water is related to the specific heat of molding material, the temperature and weight of melt and the temperature at the time of demoulding. The formula for the required ice water energy of a mold is Q=W * C * T * S. Among them:Q is the required ice water energy kcal / h;W for plastic raw material, weight kg / h;C is a plastic raw material with a specific heat of kcal / kg DEG c;T is the temperature difference between the temperature of the melt and the demoulding of the product;S is the safety factor (usually 1.35 - 2).When a single machine match, the general choice of small values, and when a cold water machine with a number of molds to match when the big value, such as the selection of air-cooled chillers, S should also be elected a big point.

- Q:How will the clamping force and injection pressure of injection mould be set?

- According to the product design of the mold to decide, you still find a master, so you can not ask what

- Q:Injection machine code

- Jiaming computer: 1688.Good view of the computer: 0000, the password is not used to adjust the model, press the "memory" button on the panel.Changxin computer: 753159168899. Otherwise: any four digit + (hour + bit +1) + (+ + bit +1) + any four digit numberNISSEI: 2227777; Sumitomo machine code: 0434201474, 7777. Friends and computers: 16885858.Best computer code: 16883297. Huada computer: 9595, level one password: 0697, four level code: 2010,Toyo universal code: 9422345, Jinfeng computer: 70648415. LS password 159753 or 083191;QC WER-MRN-52813458 is a Xintianji interval number can't be wrong, Taiwan guanpin password: 2233, universal password is: WIN-MRN-52813458Computer: 002004006 Century Fox, bampr computer: the first is: 0769, the two level is 2417755

- Q:What injection molding machine is good?

- Positioning high-tech products production marketYOFC sub group headquartered in Bavaria, Germany, Nuremberg. The team consists of a number of high-quality R & D engineers, covering all areas of research and development in full. Haitian International Holding Co., Ltd., with the subsidiary of actively expanding its market applicability, introduced the internationalization of the three brand strategy.

- Q:What is the best brand of injection molding machine?

- And a Hongkong Apollo injection molding machine, Kawaguchi in Shanghai foundry manufacturing, equivalent to Toshiba Shanghai manufacturing, this brand is the last time see in TOYOTA inside the car, first thought is Kawaguchi machine, before we know the results of Apollo, good mechanical recommend to you, according to their own products to choose suitable machine we canTaiwan: China machine series Qin, Huarong, Nan Rong, full of Taiwan, this machine, Fuqiangxing, etc.Japan Machine Series: Sadegh, Sumitomo, NISSEI, just, Kawaguchi, Niigata, Toshiba, MITSUBISHI...Europe and the United States series: Maffei Engel, Lubbock, Cincinnati, Albemarle, Demag, FANUC

- Q:What should be noticed before the machine is stopped when the injection machine is finished?

- Dongguan City Zhen Ying Machinery equipment limited company to remind you: to prolong the life of the injection molding machine, usually must take good care of!

- Q:How many tons is the injection machine of 4 Ann?

- Ann is the name of Hongkong in the last century. Ann means the amount of injection, and tons, that is, clamping force. generally speaking3 Ann -----60T4 Ann -----90T7 Ann -----120T10 Ann -----160T14 Ann -----210T17 Ann -----250T

- Q:How does the injection machine exhaust?

- It's OK to apply some oil to the oil port and then turn on the engine so that he can turn a little more

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Injection molding machine LOG-320S8/A8 QS Certification

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100000 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords