Injection Molding Machine LOG-160A8 QS Certification

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 720 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

A8 CONFIGURATIONS

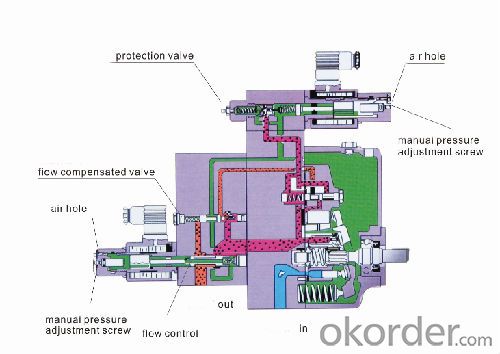

PROPORTIONAL VARIABLE PUMP YUKEN

OIL MOTOR INTERMOT

DIRECTION VALVE VICKERS

COMPUTER MIRLE 9118

AC CONTACTOR SCHNEIDER

ELECTRONIC RULER NOVO

LUBICATION PUMP HERG

Quick Details

Condition: New

Type: Other

Style: Horizontal

Brand Name: LOG

Model Number: LOG-160A8

Place of Origin: China (Mainland)

Plastic Type: Thermoplastic

Automatic: Yes

Injection Weight: 260---368G

Clamping Force: 1600KN

Opening Stroke: 430MM

Power(W): 15kw

Certification: CE

After-sales Service Provided: Engineers available to service machinery overseas

LOG160-A8 energy-saving plastic injection moulding machine

| Description | Unit | LOG-160A8 | ||

| international recognized models | 525/160 | |||

| injection | A | B | C | |

| Tjeoretical injection volume | cm³ | 277 | 318 | 392 |

| Shot volume | g | 260 | 298 | 368 |

| Oz | 9.1 | 10.5 | 12.9 | |

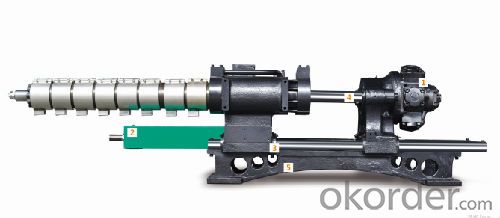

| Screw diameter | mm | 42 | 45 | 50 |

| Injection diameter | mpa | 190 | 166 | 135 |

| Screw L:D ratio | 21.4:1 | 20:01 | 18:01 | |

| Scerw steoke | mm | 200 | ||

| Screw rotate speed | r/min | 0-200 | ||

| CLAMPING UNIT | ||||

| Clamping force | kN | 1600 | ||

| Opening stroke | mm | 430 | ||

| Platen size | mm*mm | 680*680 | ||

| Space between tie bars | mm*mm | 460*460 | ||

| Maldthickness | mm | 180-500 | ||

| Platen Mix stroke | mm | 930 | ||

| Ejection stroke | mm | 140 | ||

| Ejcetion force | kN | 50 | ||

| Power/Elcetric Heating | ||||

| Hydralic system pressure | Mpa | 17.5 | ||

| Pump motor | kw | 18.7 | ||

| Heating power | kw | 12.6 | ||

| Number of temp.conteol | 4+nozzle | |||

| Other | ||||

| Cycle time | sec | 2 | ||

| Tank volume | L | 210 | ||

| Machine dimesions | m*m*m | 4.95*1.25*2.0 | ||

| Weight of machine | kg | 5100 | ||

- Q: The use of injection molding machines

- Servo energy-saving injection molding machine series, equipped with servo transmission power control system with high performance, in the process of injection molding machine in different flow pressure, make the output frequencies, and accurate closed-loop control of pressure and flow, high speed response and the best matching and automatic adjustment of the servo motor of the injection molding machine energy demand.1 、 using excellent servo controller, servo motor and other energy-saving devices.2 、 sensitive servo control system, quick start-up, reaction time is only 0.04S.3, servo motor and hydraulic system constitute closed-loop control, compared to the traditional model, the repeatability is greatly improved4, reduce the impact of the lock mold, and extend the service life of mechanical components and dies5, reduce the use of electricity, in the ideal working condition of the model than the traditional injection molding machine energy saving efficiency can reach 20%80%6, the system heat is much lower than the traditional injection molding machine, saving about 30% of the cooling water consumption, extending the oil seal and hydraulic parts life7, the whole line is running low noise, significantly lower than the traditional injection molding machine

- Q: How to check the mold opening stroke of injection molding machine

- The mould opening stroke of the injection machine should meet the need of separating the mold and removing the plastic parts. The checking of mould opening stroke is divided into the following several situations.1. the maximum opening stroke of injection molding machine has nothing to do with the die thicknessMainly refers to the clamping mechanism for injection molding machine with hydraulic machinery, such as XS-Z-30, XS-Z-60, XS-ZY-125, XS-ZY-350, XS-ZY-500, XS-ZY-1000 and G54-S200/400 type injection molding machine, the mold opening stroke by the connecting rod mechanism (or clamping cylinder) determines the maximum stroke, irrespective of the thickness of the mold.For injection mold with single parting surface:Smax = H1+H2 + mm (5 ~ 10)For injection mold with double parting surface:Smax = H1 +H2 + +a (5 ~ 10) mmType: Smax injection molding machine maximum mold opening stroke (mm);H1 plastic parts (mm, H1) launched a distance - like mold core is equal to the height, but for the plastic parts of the inner surface is stepped, sometimes do not have to launch the full height core can remove the plastic parts, then H1 can be determined according to specific circumstances, in order to successfully remove the plastic parts;H2 a piece of plastic height, including the height of the castable (mm) of the gating system that is connected to the plastic part.A the distance between the fixed die seat plate and the runner plate required by the casting system to remove the condensate (mm).

- Q: 110 tons injection molding machine injection quantity is how many grams?

- This is difficult to give you a suitable answer, because it depends on the complexity and thickness of the product you hit. Hit 300 grams, at most 200, the lower limit is not, but what the product with much of the machine is the most cost-effective, do not be a big fish in a small pond... Specific how to buy, you take the product or product drawings to vendors, they will give you an analysis of the recommendation, and will not lie to you, because people want to repeat customers.

- Q: Production calculation... 60 / 60 seconds * / / 25 x 32 / sec / mold die =1 * 12 hours per hour yield = 12 small classInjection molding machine... Production calculation... 60 / 60 seconds * / / 25 / 32 / sec * die die =1 output * 12 hours = 12 hour shifts production 55075But I don't get enough output every day... Can only do 49501 pieces, ask 49501 pieces to take several hours to be able to do... How much extra time do I have to add to the production?... Urgent urgent... Can not take a day except what count how much time yield......

- 1. are you fully automated? If it's fully automated, then you'll be able to record each exception from minutes to minutes, so you know your abnormal hours. If it is semi-automatic production, it depends on the boot staff, the door is not stable, this can be seen inside the injection molding machine.2. can not take a day except what count how much time yield......49501 / 1 hour yield = production hoursPS: personal experience, or to offer internal injection tube reported capacity of up to 23 hours of production capacity, 24h two classes, each class for half an hour maintenance and machine maintenance time is a must (of course sometimes less capacity of the interface). I used to be in accordance with 22h reported capacity, otherwise delivery can not come out, you hang up, give yourself more room.

- Q: What measures can be taken to shorten the molding process cycle of injection molding machines?

- Reduce the mold temperature, reduce the heating temperature of cylinder, increase the speed of die closing and shorten the cooling and holding time.

- Q: Which country was the injection machine invented in?

- The oldest known record is in 1872 when J.W.Hyatt in the United States solved the problem of plasticization and molding of nitrocellulose and camphor mixtures with his "packer" (US Patent No. 13329)The first machine, called an injection molding machine, was made in H.Buchholz in 1921. It is a piston type machine. Similar to the screw press at that time. Of course, this machine is driven by manpower. The first batch of injection molding machines manufactured by Eckert and Ziehler in 1926. Although its mold locking is still manual, the injection process is done with air pressure. The machine adopts a horizontal structure, and the principle is still used today.Plastic machinery in our country started in the late 50s.

- Q: Quanlifa injection molding machine can replace the barrel and screw size

- Of course, the size range not too big, we do is screw barrel.

- Q: Known diameter and displacement length of screw.

- when the product is other plastic:M (other) = (1.1~1.3) * (product weight + gating system total weight)M (PS) =1.05*W (other) / P (other)1.05 is PS density unit g/cm3P (other) for other plastic density(formula: P =M/V)

- Q: Adjust the speed of injection molding machine screw speed is what role?

- Should not be too fast, too fast will make the production of products decline, surface defects and so on! Usually between 270_350 transfers!Trouble to adopt, thank you!

- Q: Debugging and debugging process of injection molding machine

- (2) products shrinkFault reason handling methodInsufficient mold penetrationThe amount of melt is not enough, plus the amount of melt adhesiveLow glue pressure, low pressureHigh back pressure back pressure is not enoughInjection time too short injection timeInjection speed is too slow or fastThe overflow is uneven and the overflow of the mold is too small or in placeThe nozzle hole is too thin, plastic in the sprue bushing in solidification, reduce the back pressure effect. Adjust the mold or replace the nozzleMaterial temperature is too high and material temperature is lowImproper temperature and proper temperatureThe cooling time is not enough to prolong the cooling timeWhen the pressure storage section is too large, the adhesive shall terminate at the front endThe product itself or its ribs and columns are too thick to review the finished product designExcessive injection of glue to replace the finer injection molding machineWear removal of apron and adhesive screwGate is too small, plastic solidification loss, back pressure action, increase gate size

Send your message to us

Injection Molding Machine LOG-160A8 QS Certification

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 720 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords