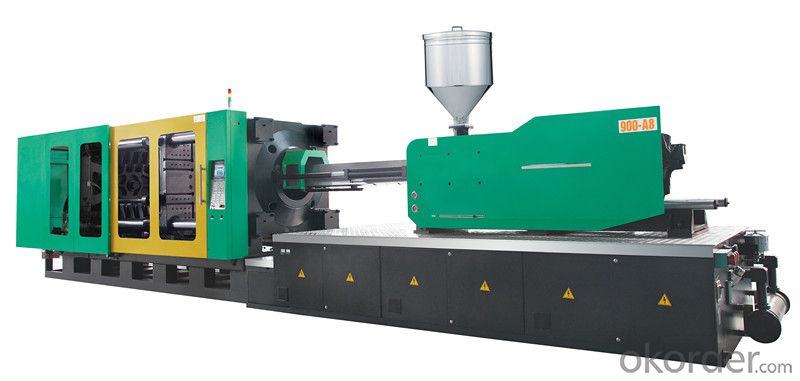

Injection Molding Machine LOG-900A8 QS Certification

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 720 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

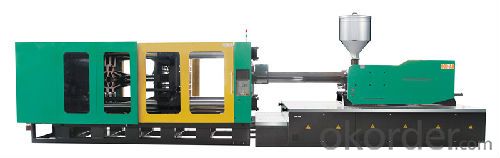

Type: Tube Head Injection

Style: Horizontal

Brand Name: LOG MACHINE

Model Number: LOG900-A8

Place of Origin: Zhejiang, China (Mainland)

Plastic Type: Thermoplastic

Automatic: Yes

Injection Weight: 2893-5143g

Clamping Force: 9000kn

Opening Stroke: 1050 mm

Power(W): 37+37 kw

Certification: CE ISO9001

After-sales Service Provided: Engineers available to service machinery overseas

Voltage: 380V

Space between Tie Bar: 1080*1030

Platen size: 1530*1530

Heating power: 58.45 kw

Oil Tank Capacity: 1900 L

Machine weight: 48T

Screw Diameter: 90-100-110-120

Ejector stroke: 300 mm

Ejector force: 270 kn

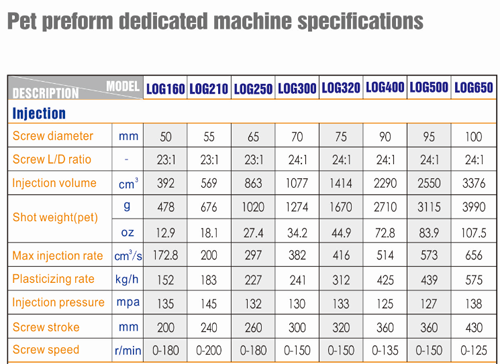

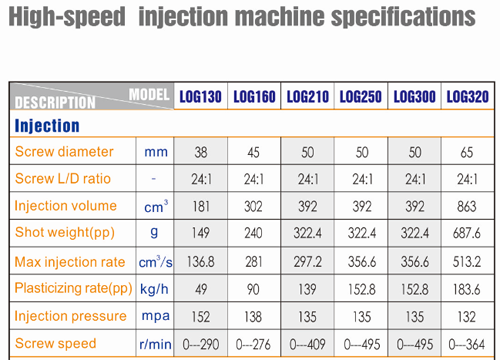

| INJECTION | LOG900 | ||||

| A | B | C | D | ||

| Shot volume | cm³ | 3179 | 3925 | 4750 | 5652 |

| Shot weight (ps) | G | 2893 | 3571 | 4321 | 5143 |

| oz | 103 | 127 | 153 | 182 | |

| Max injection rate | cm³/s | 540 | 666 | 806 | 960 |

| Screw diameter | Mm | 90 | 100 | 110 | 120 |

| Plasticizing rate | Kg/h | 291 | 378 | 503 | 600 |

| Injection pressure | Mpa | 227 | 184 | 152 | 128 |

| Screw L:D ratio | 22:01 | 22:01 | 20:01 | 18.3:1 | |

| screw speed | r/min | 0-120 | |||

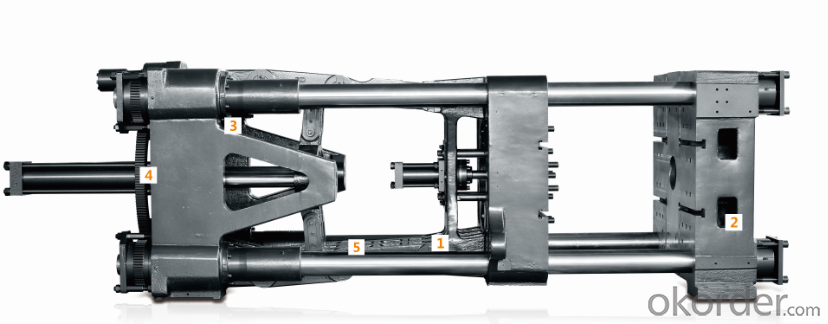

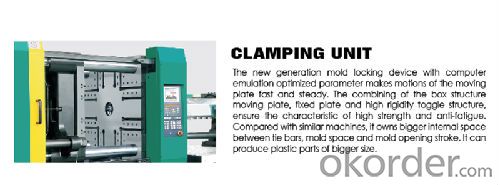

| CLAMPING | |||||

| Clamping force | Kn | 9000 | |||

| Opening stroke | Mm | 1050 | |||

| Platen size | MmXmm | 1530*1530 | |||

| Space between tie bars | MmXmm | 1080*1030 | |||

| Mold thickness (Min-Max) | Mm | 400-1100 | |||

| Hydraulic ejection stroke | Mm | 300 | |||

| Hydraulic ejection force | Kn | 270 | |||

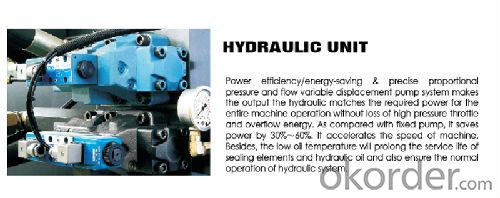

| Power Unit | |||||

| Hydraulic system pressure | Mpa | 17.5 | |||

| Pump motor | Kw | 37+37 | |||

| Heating capacity | Kw | 58.45 | |||

| Number of temp control zones | 6+ (nozzle) | ||||

| GENERAL | |||||

| Dry-cycle time | sec | 8 | |||

| oil tank capacity | L | 1900 | |||

| Machine dimensions | Mxmxm | 11*2.4*3.5 | |||

| Machine weight | kg | 48000 | |||

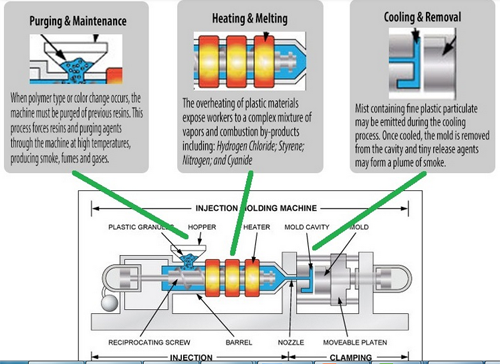

Common thermoplastic resins include:

Polyethylene PE

Polyvinyl Chloride PVC

Polypropylene PP

Polystyrene PS

Polyethlene Terephthalate PET

Acrylonitrile-butadiene-styrene ABS

Styrene-Acrylonitrile SA

Acrylic PMMA

Polyamide PA (Nylon)

Styrene-Acrylonitrile SAN

Polycarbonate PC

- Q: Can carbon fiber be used for injection molding?

- Carbon fiber can be used for injection molding, and the typical product is CF+PPS.Carbon fibers are difficult to process two times, such as drilling on molded products, plain drills, drilling holes, and drilling bits. Therefore, in the part design to avoid two machining. In addition, as with plastic and glass fiber, and carbon fiber after the screw injection molding machine screw wear increases, the life expectancy was shortened.Global carbon fiber technology and production are still largely in the hands of Japan and the United states. There are less than 20 countries and regions that can realize the industrialization of carbon fiber in the world. There are no more than 12 large-scale production enterprises. Japan, Dongli, Japan, Toho, USA, tektronix,Japan MITSUBISHI Li Yang is the global carbon fiber production capacity of the top four manufacturers, the four respectively accounted for global carbon fiber production capacity of 23.4%, 17.1%, 14.3% and 10.3%, while Chinese enterprises accounted for only 4.3%.The global carbon fiber production is mainly based on PAN based carbon fiber. In 2009, PAN based carbon fiber production capacity accounted for about 96% of the total carbon fiber production capacity of the world. The Dongli of Japan, and Toho MITSUBISHI rayon is mainly engaged in the small tow (24K) PAN based.CF+PPS 160000 yuan / tonFiber production, in 2009 this three accounted for 70.5% of the world's small tow capacity; the United States Zoltek is mainly engaged in large tow (>24K) PAN based carbon fiber production, 2009 Zoltek accounted for the global total capacity of 49.1% large tow.

- Q: What injection molding machine is good?

- Positioning high-tech products production marketYOFC sub group headquartered in Bavaria, Germany, Nuremberg. The team consists of a number of high-quality R & D engineers, covering all areas of research and development in full. Haitian International Holding Co., Ltd., with the subsidiary of actively expanding its market applicability, introduced the internationalization of the three brand strategy.

- Q: press feeding button feeding, injection machine has been feeding, storage position to still can not stop why, 15With electronic ruler control, is there an electronic ruler problem, how to judge?

- How do you determine that the feed has reached the end of the storage? Whether from the display page screw actual position to the target location is to determine if, please check whether the charging valve is electrified,

- Q: Injection molding machine rankings?

- Domestic injection molding machine brand:The first several Chun, Haitian, Dongguan Tiancheng Machinery Co., Ltd.

- Q: Does the injection machine have to use cooling water?

- If you just try machine you can not, if it is used in batches, otherwise the oil temperature will increase to a certain extent, such as the temperature of injection molding machine will alarm, high temperature of pressure and velocity is also affected.

- Q: Adjust the speed of injection molding machine screw speed is what role?

- Should not be too fast, too fast will make the production of products decline, surface defects and so on! Usually between 270_350 transfers!Trouble to adopt, thank you!

- Q: How to repair the injection machine?

- Common faults in the use of injection molding machines and solutions are as follows:Part 1: Problems and treatment methods of mould locking parts:(1) not locking dies:Handling method: 1) check the front travel switch of safety door and repair it.2) check the 24V5A power in the electric box, replace the insurance and the power box.3): check whether the spool is stuck, cleaning the spool.4): check whether the output of the I/O board, the solenoid valve is charged.5): check whether the hydraulic safety switch is closed, whether the mechanical lock rod is opened or not.(two) the opening and closing of the die machine:Handling method: 1) check whether the lubricating oil pipe is broken or, if so, reconnect the tubing.2): small amount of lubricating oil, lubricating oil amount increase, 50 die once or manually add oil and lubricating oil.3): clamping force, check whether the mold needs large clamping force, lower the clamping force.4): the current fluctuation of the amplifier board, check whether the current parameters meet the acceptance criteria, re adjust the current value.5): parallelism error indicator check head board parallelism is greater than the acceptance criteria; adjust the parallelism.

- Q: What does "120T 140T" mean in an injection machine?

- A, an abbreviation for ounce, is a unit used by the Hongkong industry to distinguish between injection molding machines. In this way, in the domestic commonly known as "T" (ton), "12" equivalent to "160T", the screw diameter of about 32 mm. In general, the injection molding machine of various specifications, there are several specifications of the screw, buyers can choose different screw size according to their uses, the screw diameter may be selected smaller, and the groove depth is also different with a shallow depth. For example, the production of PVC, will be shallow groove.Ann and T conversion is quite troublesome, here only give some common types of control: injection molding machine 4 (50T) 8 sets of injection molding machine 6 (120T) 8 sets of injection molding machine 8 (140T) 5 sets of injection molding machine 12 (160T) 5 sets of injection molding machine 16 (180T) 3 sets of injection molding machine 18 (200T) 4 sets of injection molding machine 24 (250T)

- Q: What's the difference between high-speed injection molding machine and ordinary injection molding machine?

- High speed injection molding machine is full motor, ordinary injection molding machine is hydraulic injection molding machine, and hydraulic injection molding machine relative running speed is slower. At present, the full electric injection molding machine uses servo motors to realize the die opening and closing, ejector ejection, raw material injection and storage. And so on, the operation speed is quick and precise, which greatly improves or improves the production environment and production efficiency. But now, servo electric injection molding machine only clamping force of less than 850 tons of machinery.

- Q: How does the injection machine set up the die segments and the pressure and speed of each segment? Seek advice.

- Simple injection molding closed mold process is divided into start - Fast - low pressure - high pressure four processes,Among them, the starting speed should be low speed and low voltage (usually 30% or less 40bar), the distance is about 5-10mm, and then enter the fast closed die process.Medium speed (40%-60%) and medium pressure (30-50bar) should be used in fast closed die. The distance is longer, the distance begins at low voltage protection, and the position is not finished.

Send your message to us

Injection Molding Machine LOG-900A8 QS Certification

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 720 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords