Injection Molding Machine LOG-250A8 QS Certification

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 720 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Type: Tube Head Injection

Style: Horizontal

Brand Name: LOG MACHINE

Model Number: LOG250-A8

Place of Origin: Zhejiang, China (Mainland)

Plastic Type: Thermoplastic

Automatic: Yes

Injection Weight: 464-785g

Clamping Force: 2500 kn

Opening Stroke: 520mm

Power(W): 22kw

Certification: CE ISO9001

After-sales Service Provided: Engineers available to service machinery overseas

Voltage: 380V

Screw Diameter: 50-58-65

Machine weight: 8 T

Material: Stainless Steel

Screw speed: 0-180 r/min

Function: Plastic Injection Molding Machinery

Space between Tie Bar: 560X530mm

Name: horizontal Injection Molding Machine

Ejector stroke: 150mm

Injection pressure: 132-224 mpa

Packaging Details: 20 GPcabinet

Delivery Detail: In one week after get payment

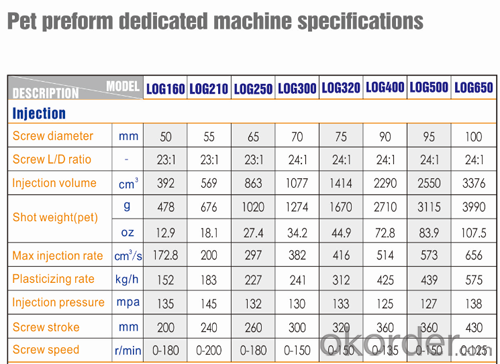

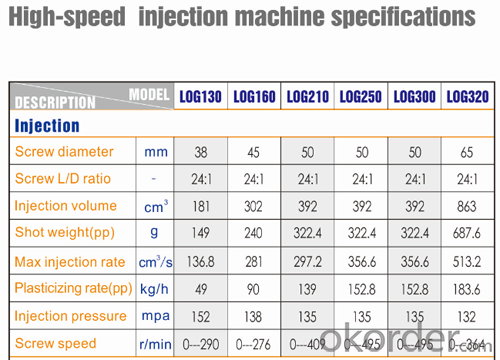

| LOG-250A8 | ||||

| International size rating | 1140/250 | |||

| INJECTION | A | B | C | |

| Shot volume | cm3 | 510 | 687 | 863 |

| Shot weight | G | 464 | 625 | 785 |

| OZ | 16.2 | 21.8 | 27.4 | |

| Screw diameter | mm | 50 | 58 | 65 |

| Injection pressure | mpa | 224 | 166 | 132 |

| Screw L:D ration | 21:01 | 21:01 | 18:07:01 | |

| Screw stroke | mm | 260 | ||

| Screw speed(stepless) | r/min | 0-180 | ||

| CLAMPING UNIT | ||||

| Clamping force | kn | 2500 | ||

| Opening stroke | mm | 520 | ||

| Platen size | mm×mm | 820×790 | ||

| Space between fie bars | mm×mm | 560×530 | ||

| Mold fhickness(Min-Max) | mm | 200-580 | ||

| Max.daylingt | mm | 1100 | ||

| Hydraulic ejection stroke | mm | 150 | ||

| Hydraulic ejection force | kn | 67 | ||

| POWER UNIT | ||||

| Hydraulic system pressure | mpa | 17.5 | ||

| Pump motor | kw | 22 | ||

| Heating capacity | kw | 16 | ||

| Number of femp confrol zones | \ | 5+ nozzle | ||

| GENERRL | ||||

| Dry-cycle fime | Sec | 4.8 | ||

| Oil fank capacify | λ | 380 | ||

| Machine dimensions | m×m×m | 6.2×1.6×2.15 | ||

| Machine weight | kg | 8000 | ||

product 1

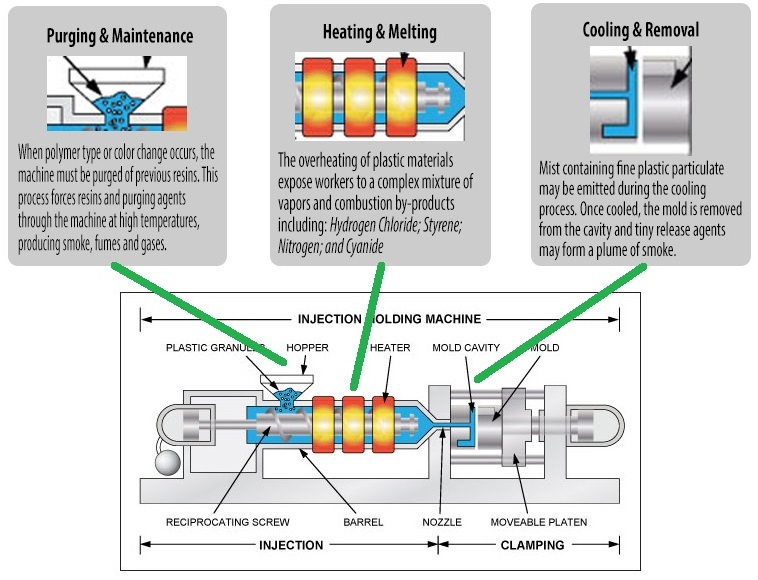

Common thermoplastic resins include:

Polyethylene PE

Polyvinyl Chloride PVC

Polypropylene PP

Polystyrene PS

Polyethlene Terephthalate PET

Acrylonitrile-butadiene-styrene ABS

Styrene-Acrylonitrile SA

Acrylic PMMA

Polyamide PA (Nylon)

Styrene-Acrylonitrile SAN

Polycarbonate PC

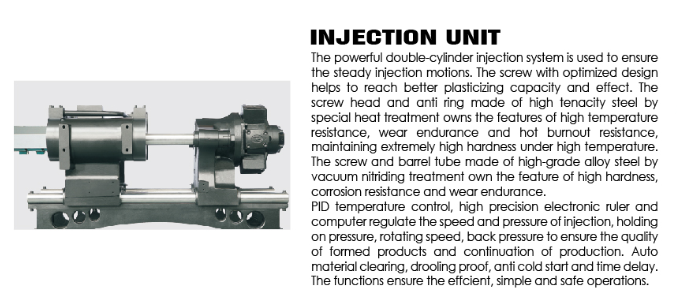

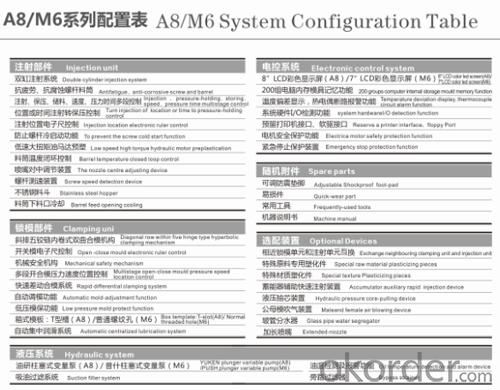

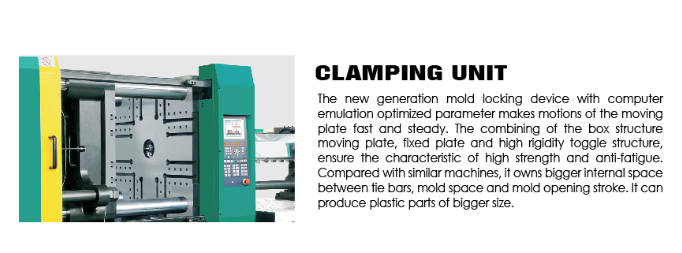

1 The mould closing unit

The new generation mold locking device and computer emulation optimized parameter makes motions of the moving plate fast and steady .When combining the box type moving plate ,fixed plate and high rigidity toggle structure ,the characteristic of high strength and anti-fatigue is secured. As compared with similar machine , it owns bigger internal spur between tie bars ,mold space and mold opening storke and may process plastic product of bigger size.

2 Computer controller

professional injection molding machine controller with software abd hardware of industrial standard is convenient to expansion and revision of performance. Adopting double CPU control makes high speed.

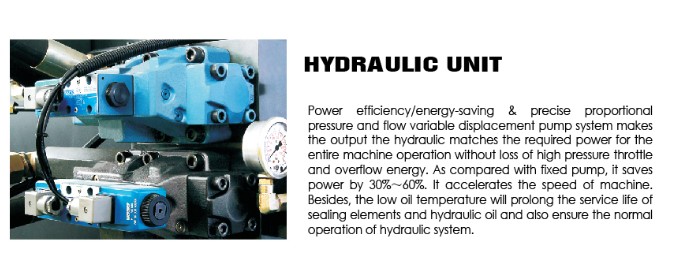

Variable Displacement Pump

1 Low Noise

Reasonable hydraulic control structure design, high integration and unipue processing in noise reduction helps machine run smoothly.

2 Oil-saving

The low oil temperature prolongs the srevice life of sealing elements .Oil cleaning equipment can filter the grease rapidly and effectively to ensure the srevice life of hydradulic elements.

3 Quick Response

The imported directly and high-response variable displacement pump achieves larger amount of emission by 20% to 25% than fixed pump driven the same motor.

4High Stability

30% to 70% energy saving compared with fixed pump under the equipment volume of work .

5 Water Saving

With no overflow and heating from variable displacement with fixed pump, 50%-75% water can be saved compared with fixed pump. Oil cleaning equipment is designed to improve the service life of hydraulic oil for 5 year.

- Q: Which high-speed machine is stable in domestic injection molding machine?

- You are the Borch machinery, should know, Guangdong has a domestic high speed machine or a treasure, what forget, of course, all electric machines in your sky, the problem is not very clear, high-speed machines specifically refers to what. If it is accurate, high-speed injection molding, domestic, there is no inflow. Personal opinions are not welcome

- Q: What should be noticed before the machine is stopped when the injection machine is finished?

- 1, stop feeding (feed off the front barrel, the barrel bottom) has been playing in the finished material2 shut down mold cooling water before stopping,3, press the manual (if not change the mold, stop the mold to the low pressure position, protect the mold)4, mold spray rust inhibitor5, turn off the electric heat6, turn off the power7, cleaning machine sanitation

- Q: From left to right nozzle middle feeding end. Someone told me that the temperature setting should high temperature to low temperature, such as from the nozzle 230220210200. Start is not so ah. Who knows what "nylon 6" as an example to say thank you.

- Injection machine cylinder temperature is set and the injection mechanism, injection volume, injection molding and relevant materials. The organic mechanism consists of a screw cylinder, design is according to the conveying, plasticizing, temperature is divided into three sections, the heating temperature is low only conveying material preheating, the inlet to prevent backflow of molten plastic is sometimes also with cooling.

- Q: Adjust the speed of injection molding machine screw speed is what role?

- Should not be too fast, too fast will make the production of products decline, surface defects and so on! Usually between 270_350 transfers!Trouble to adopt, thank you!

- Q: What are the types of injection molding machines?

- As the structure and types of injection molding products are relatively large, the injection molding machine used for molding injection products is also more.

- Q: Injection molding machine barrel, and the height of about how to adjust?

- The screw you're shooting is just adjusting the height and the left and right. If the deviation is large, the fixed seat, the piston rod, the pressure plate and the screw should be loosened.

- Q: What are the service life of domestic injection molding machines and machine tools? How do we calculate depreciation?

- I. The depreciation period of injection molding machines and machine toolsArticle sixtieth of the regulations on the implementation of the enterprise income tax law of the People's Republic of China stipulates that, in addition to the provisions of the financial and tax authorities under the State Council, the minimum amount of depreciation for fixed assets shall be as follows:(a) housing and buildings for 20 years;(two) aircraft, trains, ships, machinery, machinery and other production equipment for 10 years;(three) appliances, tools, furniture and so on related to the production and operation activities, for 5 years;(four) aircraft, trains, ships and other means of transport for 4 years;(five) electronic equipment, for 3 years.

- Q: Why should the central feed system be used in the injection molding workshop?

- The advantage of using the central feed system in the injection molding workshop is that:1. save energy2. save labor costs3. improve the company's overall image4. keep the factory environment clean and tidy5., centralized management of raw materials to avoid waste of raw materials and pollution6., can isolate the main transmission, reduce noise pollution"Dongguan niasi" the central feeding system adopts the vacuum conveying mode, through the pipeline system will focus on plastic raw materials from the storage tank is transferred to the central dehumidification system will then transport the raw material after drying to each injection molding machine. "Dongguan niasi" the central feeding system adopts "design a machine of a pipe", to ensure the whole system of raw materials for air transport, to prevent the resurgence of the raw material after drying dehumidifying. At the same time, the pipeline can be cleaned up after each conveying cycle to ensure that there is no residual granular material in the pipeline. The material performance of the injection molding machine is guaranteed to be consistent while avoiding the resurgence of the raw material. Under the vacuum negative pressure, the dust in the raw material will be filtered out through the dust filtration system, which will help to improve the quality of the molding products.Please refer to the resources below for a detailed example of the central feeding system!!!

- Q: How big is the minimum injection molding machine?

- Horizontal injection molding machine is generally the smallest in 40T, vertical minimum is 3T, the amount of injection is 15g, the working voltage is 220V, the power consumption is 0.8kw/h.Injection molding machine, also known as injection molding machine or injection machine. It is a thermoplastic or thermosetting plastic plastic molding mold made of plastic products of all shapes of the main molding equipment. It is divided into vertical, horizontal and all electric type. The injection molding machine heats the plastic, applying high pressure to the molten plastic to make it crack and fill the mold cavity.

- Q: Vertical injection molding machine in the semi-automatic state, not sol, and sometimes sol is very slow, seems to be very difficult, and sometimes simply do not turn. The problem is that it occurs during normal use, so the temperature should be fine. The parameter should be OK, too. I removed the screw and cleaned it. There was no foreign object. Under manual operation, the sol is very smooth. Consult an expert.

- First of all, you can look at you in the melt, screw rotation, the system pressure gauge to meet the pressure you set, if not achieved, that is, the system pressure is out of orderAnd then you are in the process of melting, whether there is abnormal sound, if there is the adhesive, motor seat inside the bearings damagedNext, look at your material is doped with excessive toner and so onFOMTEC plastic, I hope to help you

Send your message to us

Injection Molding Machine LOG-250A8 QS Certification

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 720 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords