Injection Molding Machine LOG-300A8 QS Certification

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 720 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Condition: New

Type: Tube Head Injection

Style: Horizontal

Brand Name: LOG MACHINE

Model Number: LOG300-A8

Place of Origin: Zhejiang, China (Mainland)

Plastic Type: Thermoplastic

Automatic: Yes

Injection Weight: 673-980g

Clamping Force: 3000 kn

Opening Stroke: 570 mm

Power(W): 22kw

Certification: CE ISO9001

After-sales Service Provided: Engineers available to service machinery overseas

Product name: Plastic Rubber Injection Moulding Machine

Warranty: One Year

Material: Stainless Steel

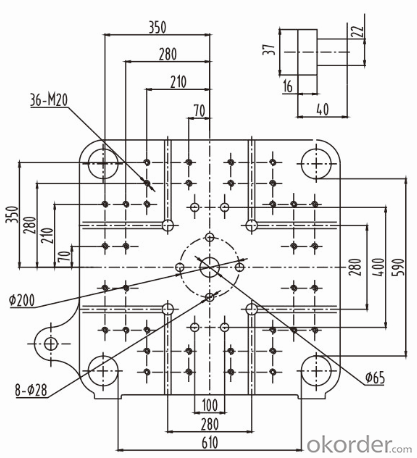

Space between Tie Bar: 610*590

Screw Diameter: 58-65-70 mm

Machine weight: 9.1T

Ejector stroke: 160mm

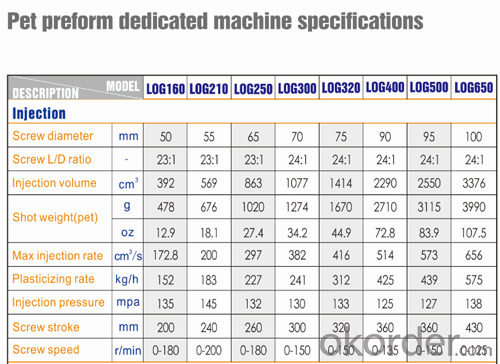

| Description | Unit | LOG-300A8 | ||

| international recognized models | 1400/300 | |||

| injection | A | B | C | |

| Tjeoretical injection volume | cm³ | 740 | 929 | 1077 |

| Shot volume | g | 673 | 845 | 980 |

| Oz | 23.5 | 29.5 | 34.2 | |

| Screw diameter | mm | 58 | 65 | 70 |

| Injection diameter | mpa | 190 | 151 | 130 |

| Screw L:D ratio | 24:01:00 | 22:01 | 20:01 | |

| Scerw steoke | mm | 300 | ||

| Screw rotate speed | r/min | 0-150 | ||

| CLAMPING UNIT | ||||

| Clamping force | kN | 3000 | ||

| Opening stroke | mm | 570 | ||

| Platen size | mm*mm | 870*850 | ||

| Space between tie bars | mm*mm | 610*590 | ||

| Maldthickness | mm | 200-600 | ||

| Platen Mix stroke | mm | 1170 | ||

| Ejection stroke | mm | 160 | ||

| Ejcetion force | kN | 77 | ||

| Power/Elcetric Heating | ||||

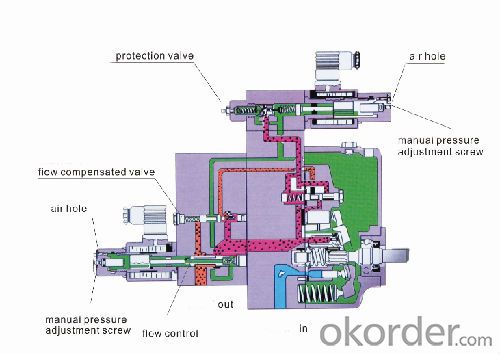

| Hydralic system pressure | Mpa | 17.5 | ||

| Pump motor | kw | 29 | ||

| Heating power | kw | 23.6 | ||

| Number of temp.conteol | 5+nozzle | |||

| Other | ||||

| Cycle time | sec | 5 | ||

| Tank volume | L | 380 | ||

| Machine dimesions | m*m*m | 6.4*1.6*2.18 | ||

| Weight of machine | kg | 11000 | ||

Packaging & Delivery

| Packaging Details: | Packaging Details: 20 GPcabinet Delivery Detail: In one week after get payment |

|---|

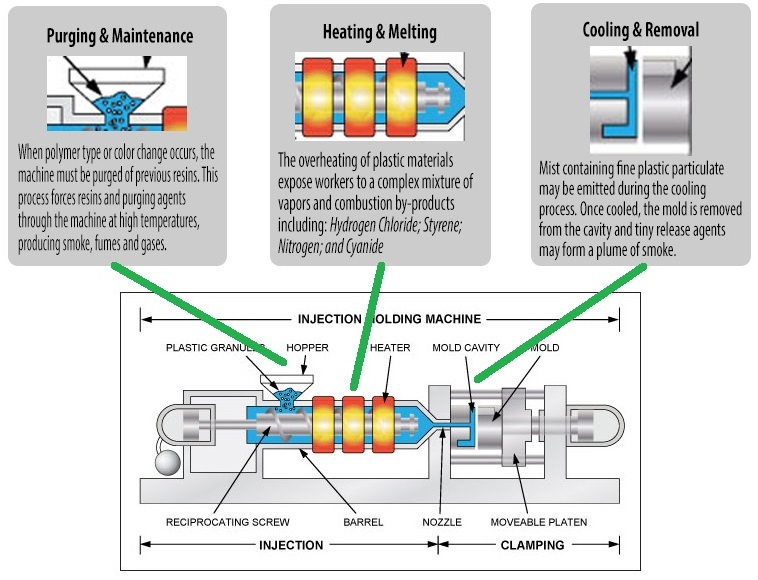

Common thermoplastic resins include:

Polyethylene PE

Polyvinyl Chloride PVC

Polypropylene PP

Polystyrene PS

Polyethlene Terephthalate PET

Acrylonitrile-butadiene-styrene ABS

Styrene-Acrylonitrile SA

Acrylic PMMA

Polyamide PA (Nylon)

Styrene-Acrylonitrile SAN

- Q: What kind of lubricant does the injection machine use?

- Ann beauty injection molding machine hydraulic oil HM68 number.

- Q: Injection molding machine clamping force appropriate, can speak a little detail, thank you

- This machine is calculated according to the projected area of the product clamping force, the clamping force must be greater than the cavity pressure, otherwise it will lock mode, causing flash

- Q: Injection molding machine rankings?

- Haida machine, A Well-Known Trademark in China, national Mianjian products, high-tech enterprise, Zhejiang famous brand, Zhejiang famous trademarks, China Plastic Machinery Industry Association executive director of the unit.

- Q: Injection molding machine products shrink, how to solve?

- Injection pressure, holding pressure, speed, back pressure, temperature, glue content, inlet and die temperature

- Q: Quanlifa injection molding machine can replace the barrel and screw size

- Screw barrel size can change, but can not change too much, too big to carry motor and screw will not rotate, change is too small, you have to look at the ratio of length to diameter, ratio of length to diameter is too large, easily broken screw.

- Q: When the injection machine is ejected, does the screw screw rotate?

- We call it a battery, and I don't know what you call it

- Q: What's the injection?

- I. The main contents of the injection molding staff are as follows:1. Responsible for the improvement, preparation and execution of injection molding technology;2. Test the new product and determine the best technological parameters, identify the defects of the product and mould and perfect it;3. Analyze the process of defective products during production and provide solutions and improvement plan;4, the injection molding machine, mold and other equipment maintenance plan formulation and routine maintenance of the implementation, ensure equipment and process safety, quality, ability and utilization rate to achieve the best.5, accept the workshop supervisor's instruction, complete the product quality and quantity, the injection work on time;6, familiar with the process principle, in strict accordance with the quality requirements of the process operation;7. Ensure the achievement of all production target tasks and cooperate with the system review;8. Complete other work assigned by the leader.

- Q: How much is the ejection rate of injection molding machine?

- Generally transferred to 4, to 6 can be, I hope my answer will help you - Switek

- Q: How the elite injection molding machine sales in Southern China?

- Not how the elite injection molding machine is low, I used, not very easy to use. The quality is poor and the price is cheap

- Q: What factories in Shenzhen area have injection molding machines? What's the number?

- Shenzhen grand Electromechanical Technology Co., Ltd., all electric injection molding machine, energy saving, environmental protection, precision, improve production efficiency.

Send your message to us

Injection Molding Machine LOG-300A8 QS Certification

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 720 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords