Injection Molding Machine LOG-400A8 QS Certification

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 720 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Condition: New

Type: Tube Head Injection

Style: Horizontal

Brand Name: LOG

Model Number: LOG-400A8

Place of Origin: Zhejiang, China (Mainland)

Plastic Type: Thermoplastic

Automatic: Yes

Injection Weight: 1646g

Injection Rate: 406cm3/s

Clamping Force: 4000KN

Opening Stroke: 670mm

blue: energy saving

Packaging & Delivery

| Packaging Details: | one machine in a 40GP container |

|---|---|

| Delivery Detail: | a week if it's at stock OR a month |

Specifications

1.high response 2. high precise,3oil saving 4. water saving 5.long working life

details :

LOG-400A8 | ||||

International size rating | 2860/400 | |||

INJECTION | A | B | C | |

Shot volume | cm3 | 1385 | 1810 | 2290 |

Shot weight | G | 1260 | 1646 | 2084 |

OZ | 44.1 | 57.5 | 72.8 | |

Screw diameter | mm | 70 | 80 | 90 |

Injection pressure | mpa | 206 | 158 | 125 |

Screw L:D ration | 21:1 | 21:1 | 19:1 | |

Screw stroke | mm | 360 | ||

Screw speed(stepless) | r/min | 0-135 | ||

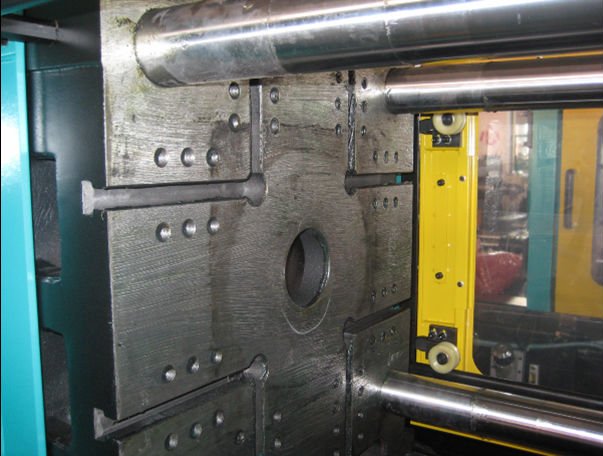

CLAMPING UNIT | ||||

Clamping force | kn | 4000 | ||

Opening stroke | mm | 670 | ||

Platen size | mm×mm | 1060×1040 | ||

Space between fie bars | mm×mm | 730×710 | ||

Mold fhickness(Min-Max) | mm | 250-730 | ||

Max.daylingt | mm | 1400 | ||

Hydraulic ejection stroke | mm | 185 | ||

Hydraulic ejection force | kn | 111 | ||

POWER UNIT | ||||

Hydraulic system pressure | mpa | 17.5 | ||

Pump motor | kw | 37 | ||

Heating capacity | kw | 32.3 | ||

Number of femp confrol zones | \ | 5+ nozzle | ||

GENERRL | ||||

Dry-cycle fime | sec | 5.1 | ||

Oil fank capacify | λ | 820 | ||

Machine dimensions | m×m×m | 8.6×1.75×2.35 | ||

Machine weight | kg | 17000 | ||

- Q: Can carbon fiber be used for injection molding?

- 1 carbon fiber can be used for injection molding.2, carbon fiber (carbon fiber, referred to as CF), is a carbon content of more than 95% of high strength, high modulus fibers of new fibers. It is a flaky graphite, microcrystalline and other organic fibers stacked along the axial direction of the fiber, obtained by carbonization and graphitization of microcrystalline graphite material. Carbon fiber "an hand in a velvet glove lighter than aluminum," the quality, but the strength is higher than that of steel, and has the characteristics of corrosion resistance, high modulus, in the national defense and civilian areas are important materials. It has not only the intrinsic characteristics of carbon materials, but also the softness and processability of textile fibers. It is a new generation of reinforced fiber.3 、 injection molding is an industrial product modeling method. Products are typically molded by rubber injection and plastic injection. Injection molding can also be divided into injection molding, die casting and die casting. Injection molding machine (referred to as the injection molding machine or injection molding machine) is plastics molding equipment of thermoplastic or thermosetting material using plastic mold made of various shapes, injection molding by injection molding machine and mold.

- Q: What are the main parts of an injection molding machine?

- (1) the function of injection system in injection molding system: injection system is one of the most important parts of injection molding machine. There are 3 main forms, plunger type, screw type, screw type, pre plastic plunger and injection type. Screw type is the most widely used at present. It is, in a circular plastic injection machine, within a specified time will be a certain number of plastic heating plasticization, pressure and velocity in the screw, through the molten plastic is injected into the mold cavity. At the end of the injection, the melt is injected into the mold cavity to retain the shape. Injection system: injection system consists of plasticizing device and power transmission device. The plasticizing device of screw type injection molding machine is mainly composed of feeding device, material barrel, screw rod and nozzle. The power transmission device includes an injection cylinder, an injection seat, a moving cylinder, and a screw drive device (a melt motor). (2) the function of the die closing system: the function of the die closing system is to ensure the die closing, opening and ejection. At the same time, in the mold closed, to give the mold enough clamping force, in order to resist the molten plastic into the mold cavity cavity pressure, to prevent the mold slit, resulting in the bad situation of the product. The die making system consists of a die clamping device, a die adjusting mechanism, an ejector mechanism, a front and rear clamping plate, a moving die plate, a die cylinder and a safety protection mechanism.

- Q: What are the common problems and solving methods of injection molding machine? The more detailed, the better the month

- Common faults and elimination methods of injection molding machineNon locking modeA, close the front and rear door safely;B and check whether the safety threshold switch works properly;C, check the thimble recession switch;D, check mode lock electronic ruler and die stop switch;E, check mould parameter, speed, pressure and position setting is correct;F check whether the coil of the mould valve is live or not and whether the spool is working properly;G, the mold thickness adjustment or switch mode switch open, in the automatic state can not die;H, if there is a hydraulic safety lock, check whether it is normal.Open moldA and check the test status of the electronic ruler;B check whether the coil of the mould valve is live or not and whether the spool is working properly;C, if the high pressure mode locking down time is too long, because the metal structure related to the elastic deformation caused not opening, approach: a) to improve the opening speed, pressure, pressure reducing opening time, b) in general can be opened;D, if there are core pulling, twisting and other operations in the opening die, the working state of the lock die is not normal, so it is necessary to check whether the start and stop signals of these actions are normal.Die adjustmentA, mode adjustment counting switch fault;B and the original position change of the mould (in this case only one way adjustment)C, regulating valve coil is charged, and spool work is normal;D, the working state of the regulating motor;E, the die nut dies.

- Q: What is a vertical injection molding machine?

- Vertical injection molding machine:1 、 vertical non column lock mold, horizontal injection molding, mold three sides open, more convenient and safe operation.2 、 injection pressure, torque hydraulic motor control, large spiral torque, high pre plastic, the system pressure by the proportional valve control.3, multi section pressure output, pressure sensitive, accurate and accurate.4 、 can install single, double slide, turntable system to improve production efficiency.5, suitable for the production of large doses of brain glue.

- Q: Please expert advice...... Thank youLarge barrel nozzle lock does not leak out of glue...... Lead to product dissatisfaction......

- This problem, first check the screw barrel, screw ring will stop should be broken, can be replaced.

- Q: Relative to the size of the installation mold, it can also be said to be the internal column or guide column of the injection molding machine. How can this part be translated in English?

- Tie Bars--- pull rod (Ge Linzhu)Clearamce Between Tie Bars is the column spacing is between the Green column, you said the distance, Green column spacing also restricted the installation of the width of the mold, the mold width must be less than the Green column spacing can be put under the lock on shot out!

- Q: How many grams of 200t injection molding machine?

- Heating part energy saving: heating part energy saving, mostly using electromagnetic heater energy saving, energy saving rate is about 30%-70% of old resistance ring.1. compared with the resistance heating, the electromagnetic heater has a layer of thermal insulation layer, and the heat energy utilization rate is increased.2. compared with the resistance heating, the electromagnetic heater acts directly on the tube heating, reducing the heat transfer and thermal energy loss.

- Q: How to calculate the capacity of mold injection molding?

- The counter machine with opening times ah, before you boot reset, see how much time and work mode, then take out the number of the first mock exam will be able to come out of the number of products, and then go to work for a long time to know how much time ah

- Q: How to adjust the injection molding machine, how to solve the shrinkage of injection molding products?

- Shrinkage (Sink, marks, or shrinkage) is one of the defects in injection molding.ApparentThere is a dent in the accumulation area of the surface material of the plastic parts. The shrinkage occurs mainly in the thick part of the plastic wall or in the change of the wall thickness.Physical reasonsWhen the product is cooled, shrinkage (decrease in volume, shrinkage) occurs at the time where the outer wall of the die is frozen first, and the inner center of the work product forms an internal stress. If the stress is too high, it will cause plastic deformation of the outer plastic. In other words, the outer layer will sag inwards. If the shrinkage occurs and the deformation of the outer wall is not stable (as it has not cooled), the pressure shall not be added to the melt and the mold will settle between the die wall and the solidified outer layer of the product.These settlements are usually seen as shrinkage. If the product has a thick cross section, this shrinkage may also occur after demoulding. This is because there is still heat inside, and it passes through the outer layer and heats up the outer layer. The tensile stress produced in the product causes the thermal outer layer to settle inward, forming shrinkage during this process.

- Q: What is low voltage protection (injection molding machine)?

- For example, when there is something on the surface of the mold to fit the mold, it will open the mold automatically in order not to damage the mold. This process is low voltage protection.

Send your message to us

Injection Molding Machine LOG-400A8 QS Certification

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 720 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords