injection molding machine LOG-130S8 QS Certification

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100000 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Condition: | New | Type: | Tube Head Injection | Style: | Horizontal |

| Brand Name: | LOG | Model Number: | LOG 130S8 | Place of Origin: | Zhejiang, China (Mainland) |

| Plastic Type: | Thermoplastic | Automatic: | Yes | Injection Weight: | 239 |

| Clamping Force: | 1300kn | Opening Stroke: | 380mm | Power(W): | 12kw |

| Certification: | CE | After-sales Service Provided: | Engineers available to service machinery overseas |

Packaging & Delivery

| Packaging Details: | 20GP,40GP,40HQ |

| Delivery Detail: | 30 Days |

Product performance and advantages:

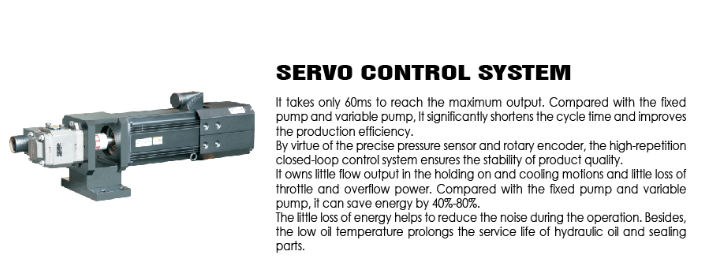

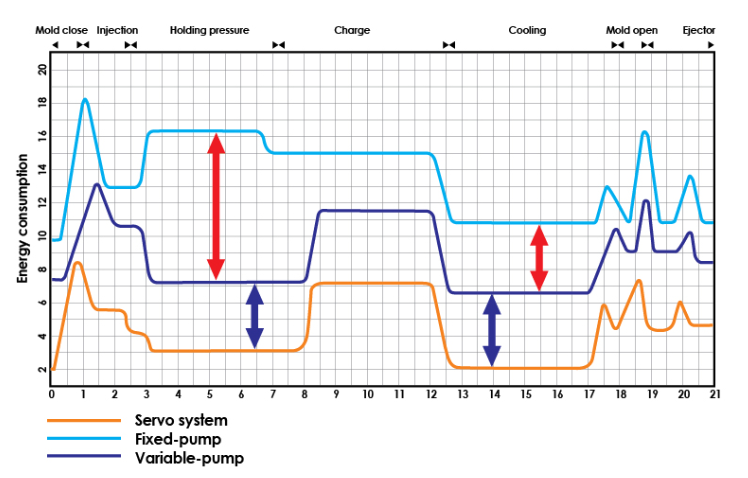

1. Servo energy-saving system

Using the servo motor oil electricity composite structure

2. Servo motor high response feature

It costs only 0.05s for servo energy saving injection molding machines to achieve the maximum output, in

comparison with conventional hydraulic injection molding machines. The response speed has been obviously

increased, improving the production efficiency.

3. Unique function

Large colored screen with TFT interface

Full automatic close-loop control

Module design of hardware

Auto-tune PID temperature control

Pc interface USB, PIC, and FLASH…

Curve monitoring and analysis function

K-can data transmission (500Kbit/s)

On-line central monitoring function

LOG-130S8 Technical parameters

Description | Unit | LOG-130S8 | ||

international recognized models | 416/130 | |||

injection | A | B | C | |

Tjeoretical injection volume | cm³ | 215 | 263 | 302 |

Shot volume | g | 196 | 239 | 274 |

Oz | 6.9 | 8.4 | 9.6 | |

Screw diameter | mm | 38 | 42 | 45 |

Injection diameter | mpa | 193 | 158 | 138 |

Screw L:D ratio | 22:1 | 20:1 | 18:1 | |

Scerw steoke | mm | 190 | ||

Screw rotate speed | r/min | 180 | ||

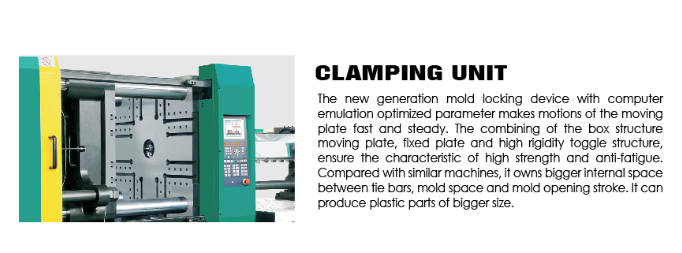

CLAMPING UNIT | ||||

Clamping force | kN | 1300 | ||

Opening stroke | mm | 380 | ||

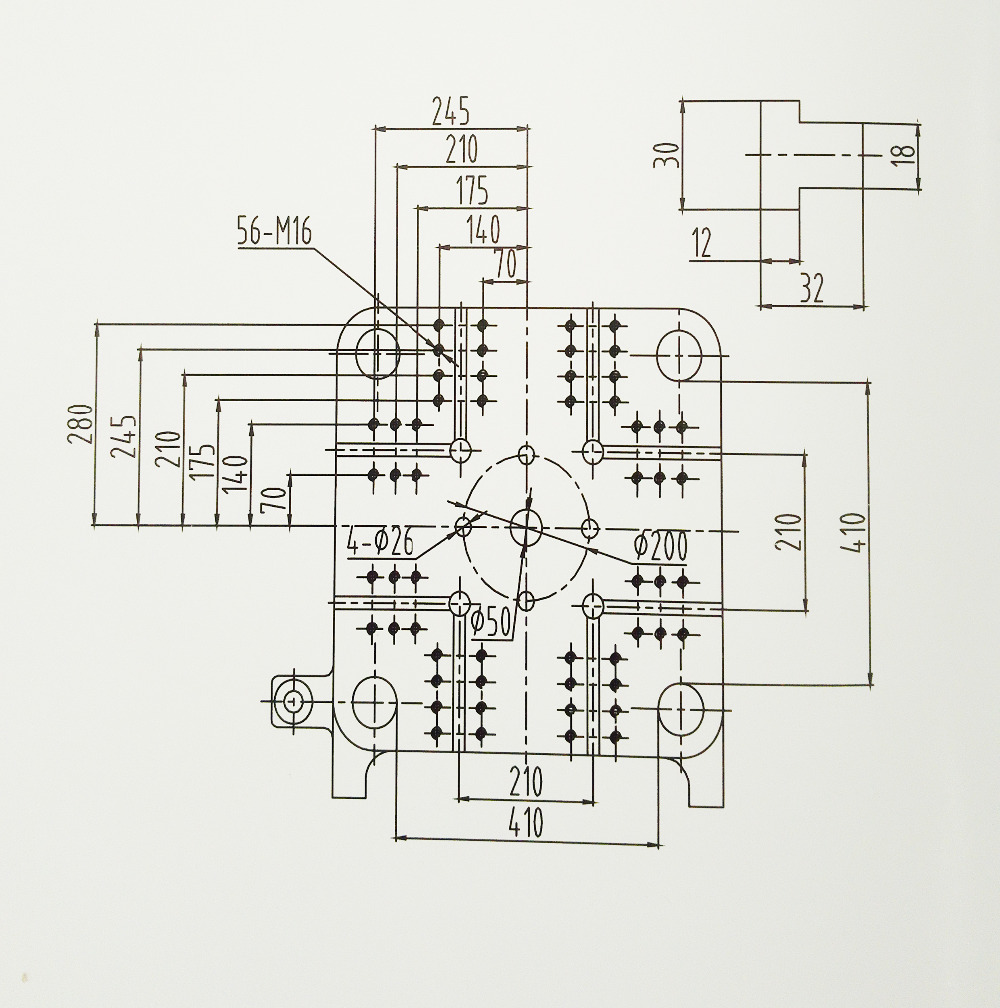

Platen size | mm*mm | 610*610 | ||

Space between tie bars | mm*mm | 410*410 | ||

Maldthickness | mm | 150-430 | ||

Platen Mix stroke | mm | 810 | ||

Ejection stroke | mm | 120 | ||

Ejcetion force | kN | 42 | ||

Power/Elcetric Heating | ||||

Hydralic system pressure | Mpa | 17.5 | ||

Pump motor | kw | 12 | ||

Heating power | kw | 7.7 | ||

Number of temp.conteol | 4+nozzle | |||

Other | ||||

Cycle time | sec | 1.3 | ||

Tank volume | L | 200 | ||

Machine dimesions | m*m*m | 4.6*1.2*1.8 | ||

Weight of machine | kg | 4000 | ||

Platen Dimensions:

product

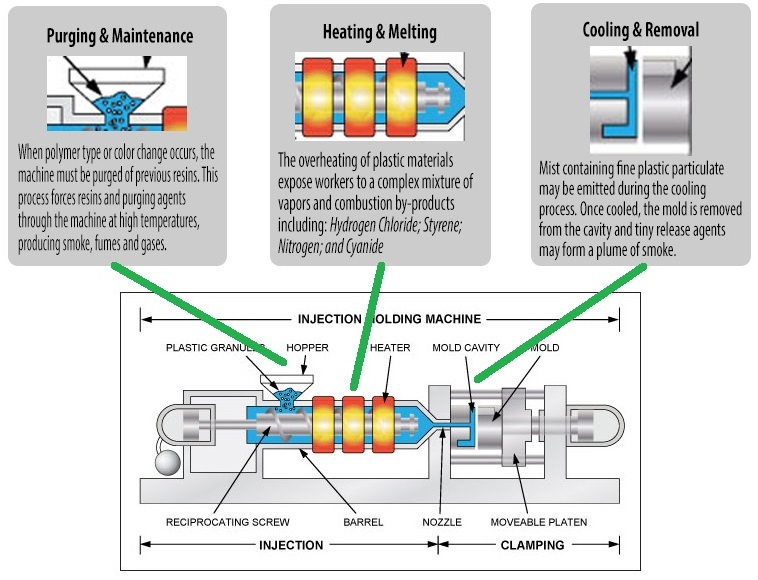

Common thermoplastic resins include:

Polyethylene PE

Polyvinyl Chloride PVC

Polypropylene PP

Polystyrene PS

Polyethlene Terephthalate PET

Acrylonitrile-butadiene-styrene ABS

Styrene-Acrylonitrile SA

Acrylic PMMA

Polyamide PA (Nylon)

Styrene-Acrylonitrile SAN

Polycarbonate PC

- Q: What are the main parts of an injection molding machine?

- (1) the function of injection system in injection molding system: injection system is one of the most important parts of injection molding machine. There are 3 main forms, plunger type, screw type, screw type, pre plastic plunger and injection type. Screw type is the most widely used at present. It is, in a circular plastic injection machine, within a specified time will be a certain number of plastic heating plasticization, pressure and velocity in the screw, through the molten plastic is injected into the mold cavity. At the end of the injection, the melt is injected into the mold cavity to retain the shape. Injection system: injection system consists of plasticizing device and power transmission device. The plasticizing device of screw type injection molding machine is mainly composed of feeding device, material barrel, screw rod and nozzle. The power transmission device includes an injection cylinder, an injection seat, a moving cylinder, and a screw drive device (a melt motor). (2) the function of the die closing system: the function of the die closing system is to ensure the die closing, opening and ejection. At the same time, in the mold closed, to give the mold enough clamping force, in order to resist the molten plastic into the mold cavity cavity pressure, to prevent the mold slit, resulting in the bad situation of the product. The die making system consists of a die clamping device, a die adjusting mechanism, an ejector mechanism, a front and rear clamping plate, a moving die plate, a die cylinder and a safety protection mechanism.

- Q: Is not the European standard template meaning, that is not a standard installation spacing, screw holes, thimble holes?. There is also a SPI standard. Do you have the standard data in this respect?

- It is divided into vertical, horizontal and all electric type. The injection molding machine heats the plastic, applying high pressure to the molten plastic to make it crack and fill the mold cavity

- Q: How many tons is the injection machine of 4 Ann?

- Ann is the name of Hongkong in the last century. Ann means the amount of injection, and tons, that is, clamping force. generally speaking3 Ann -----60T4 Ann -----90T7 Ann -----120T10 Ann -----160T14 Ann -----210T17 Ann -----250T

- Q: How can the injection machine be set with parameters?

- 4. check the cooling pipe for long distance flow, and the oil cooler and barrel end of the cooling water jacket into the cooling water.5. before the injection machine operation, check whether there is lubrication in each moving part, and add enough lubricating oil.6. turn on the heater and heat the barrel. When the temperature of each section meets the requirements, the insulation will be kept warm for a period of time to keep the machine temperature stable. Holding time varies according to the requirements of different equipment and plastic raw materials.7. add enough plastic to the hopper. According to the injection of different plastic requirements, some of the raw material is best to go through drying.8., the heat insulation cover on the cylinder can be covered, so that the electric energy can be saved, and the service life of the electric heating coil and the current contactor can be prolonged.Operation process1., not for convenience, and arbitrarily cancel the role of security doors.2. pay attention to observe the temperature of the pressure oil, the oil temperature should not exceed the prescribed range. The ideal working temperature of hydraulic oil should be kept between 45-50 degrees centigrade, which is suitable for the range of 35-60 centigrade.3. attention to adjust the travel switch, to avoid the machine in the action of impact.End-of-job1. after the injection molding machine operation is completed, the cylinder should be cleaned of plastic, to prevent residual oxidation or long-term thermal decomposition.2. should be open to the mold, the toggle mechanism is in the locked condition of time.3. workshop must be equipped with lifting equipment. When handling dies, care shall be taken to ensure safety in production.

- Q: How does the injection machine exhaust?

- 1, the mold cylinder formed a negative pressure, inhalation of air from the outside. Concrete method: first, apply the butter on the joint surface of the connecting parts, make several opening and closing dies, observe whether there is any change or not. If so, tighten the screws and joints tightly.2, check whether the suction pump air. Specific methods: check whether the oil absorption port layout specifications; oil in the air will be removed.3 、 the pipeline is too long or the suction height is too high, it is difficult to exhaust. Specific method: with exhaust valve, repeatedly doing the opening and closing mold action exhaust; if not, then have to design and install a slightly (usually in the highest position).4, is it a new cylinder, or repair mold cylinder, or did not start for many days?. In this case, do more warm-up exercises, the air naturally discharged.

- Q: Domestic injection molding machine which brands are better?

- High exposure... Shock bear, Iraq's secret, Bo Chuang, Donghua

- Q: Not transformer. It's wires and meters. Because the transformer is public. If 10 kilowatts is not enough. How much is enough?

- 160T injection molding machine, if you want to use electromagnetic heating control panels for energy-saving transformation, the easiest way is to determine the original electric heating block is a few areas? What is the power of each zone? Then, in accordance with this to match the line, a few zones with several electromagnetic heating control panels, the power of each board and the power of the same heat block, or close to the line. In this way, the power saving rate can reach more than 40%, and the production efficiency can also be improved by about 20%. The friend in need can find Xin Rui energy saving manager, consult the order, and have professional technical guidance!

- Q: What kind of after-sales service, which friends know to introduce?

- The best thing is the company's low pressure injection molding machine, and many famous brands are looking for them to process low voltage injection molding machines, such as apple, Microsoft, and the United states.

- Q: What is the meaning of injection molding machine before melting and pumping and after melting? What's the function of 10?

- Injection molding machine melting process is through the rotation of the screw, the material inside the bucket through the screw to the front end of the screw rod propulsion, screw rotation is not only itself active back, when the barrel material is pushed to the front end of the screw in the front of the barrel, the pressure will be more and more, will be forced to retreat when the screw, screw back the set position, the screw stops rotating, melt end. In order to prevent the pressure in the barrel is too large but the glue flows out from the nozzle, usually used to pumping (also called loosening, cable, shot back down), the active screw back a certain distance (usually a few mm) to remove part of the pressure.

Send your message to us

injection molding machine LOG-130S8 QS Certification

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100000 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords