injection molding machine LOG-250S8/A8 QS Certification

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100000 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Condition: New

Type: Tube Head Injection

Style: Horizontal

Brand Name: LOG

Model Number: LOG 250S8

Place of Origin: Zhejiang, China (Mainland)

Plastic Type: Thermoplastic

Automatic: Yes

Injection Weight: 625

Clamping Force: 2500kn

Opening Stroke: 520mm

Power(W): 29kw

Certification: CE

After-sales Service Provided: Engineers available to service machinery overseas

Packaging & Delivery

| Packaging Details: | 20GP,40GP,40HQ |

|---|---|

| Delivery Detail: | 30 Days |

Product performance and advantages:

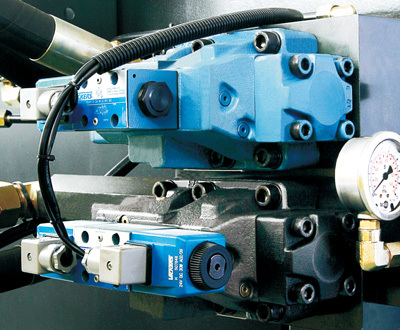

1. Servo energy-saving system

Using the servo motor oil electricity composite structure

2. Servo motor high response feature

It costs only 0.05s for servo energy saving injection molding machines to achieve the maximum output, in comparison with conventional hydraulic injection molding machines. The response speed has been obviously increased, improving the production efficiency.

3. Unique function

Large colored screen with TFT interface

Full automatic close-loop control

Module design of hardware

Auto-tune PID temperature control

Pc interface USB, PIC, and FLASH…

Curve monitoring and analysis function

K-can data transmission (500Kbit/s)

On-line central monitoring function

LOG-250S8 Technical parameters

Description | Unit | LOG-250S8 | ||

international recognized models | 1140/250 | |||

injection | A | B | C | |

Tjeoretical injection volume | cm³ | 510 | 687 | 863 |

Shot volume | g | 464 | 625 | 785 |

Oz | 16.2 | 21.8 | 27.4 | |

Screw diameter | mm | 50 | 58 | 65 |

Injection diameter | mpa | 224 | 166 | 132 |

Screw L:D ratio | 24:1 | 21:1 | 18.7:1 | |

Scerw steoke | mm | 260 | ||

Screw rotate speed | r/min | 0-180 | ||

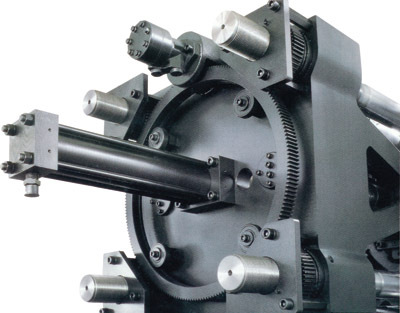

CLAMPING UNIT | ||||

Clamping force | kN | 2500 | ||

Opening stroke | mm | 520 | ||

Platen size | mm*mm | 820*790 | ||

Space between tie bars | mm*mm | 560*530 | ||

Maldthickness | mm | 200-580 | ||

Platen Mix stroke | mm | 1100 | ||

Ejection stroke | mm | 150 | ||

Ejcetion force | kN | 67 | ||

Power/Elcetric Heating | ||||

Hydralic system pressure | Mpa | 17.5 | ||

Pump motor | kw | 29 | ||

Heating power | kw | 16 | ||

Number of temp.conteol | 4+nozzle | |||

Other | ||||

Cycle time | sec | 4.8 | ||

Tank volume | L | 380 | ||

Machine dimesions | m*m*m | 6.2*1.46*2.15 | ||

Weight of machine | kg | 8000 | ||

- Q: Injection back pressure problem

- Formation of back pressure in injection moldingFirst, the formation of back pressureIn the process of melting and plasticizing of plastics, the melt moves to the front of the barrel and more and more, gradually forming a pressure to push the screw back. In order to prevent the screw from backing too fast and to ensure uniform compaction of the melt, it is necessary to provide an opposite direction of pressure to the screw, which is the reverse pressure that prevents the screw from retreating. Back pressure is also known as plasticizing pressure, and its control is achieved by adjusting the oil return valve of the injection cylinder. Pre injection plasticizing screw injection molding machine is equipped with the rear end of the oil cylinder back pressure valve, regulating screw back when the injection cylinder oil cylinder speed, to maintain a certain pressure; shift speed screw motor after (resistance) is composed of AC servo valve control.

- Q: What kinds of lubricants are used in the injection molding machine?

- Recently to see a lot of customers, with injection molding, stamping do, also do die, ask how the hydraulic oil inside the equipment they use, change a long oil ah, why to change the oil and so on, answer the baseThis is a dirty oil, water, use of time, and so on, we do not have time to change, for a few months, one year, two or three years, and the oil, that you have thought about these can be the cause of the oil?Here I would like to discuss the use of lubricating oil, lubricating oil scrap standards,Baidu search, it was posted that the deterioration of lubricating oil for the following reasons:1, lubricating oil is black (without detergent dispersant additives in lubricating oil).2, foam and emulsification has occurred.3, with fingers twist, the ground sticky feeling, hair acerbity or peculiar smell.4, drops on the white paper is dark brown, no yellow infiltration, slippery spots or black spots.thisIn fact, some problems can not be bad, because before there is not a good way to get him back, so we all think bad, more than 4 points, after all the following points, the first water emulsion,

- Q: How to reset the EM-120 origin of the injection machine?

- Setting method:1, the high pressure die termination position is set to 0 P2, mold opening to the end;3, press cancel + high voltage lock mode, 3 seconds appear origin setting screen;4, enter 9999 at the preset mode 1; move the cursor back to the preset 1; enter a question mark by the input; Press confirm again;5, press the button manually. Ejection of products; about 10MM after mold adjustment;

- Q: What is the temperature of the NH, H and HP on the injection machine screen?

- Injection molding machine in the lock mode, the thimble is to look back, not open mold, to see if the parameters are set incorrectly, press the mold opening, the volume of mold opening valve, there is no electricity

- Q: What should be noticed before the machine is stopped when the injection machine is finished?

- Dongguan City Zhen Ying Machinery equipment limited company to remind you: to prolong the life of the injection molding machine, usually must take good care of!

- Q: Process knowledge of plastic injection machine head

- Glue head (Zhi Nihuan) had a rubber rubber meson, materials can be selected full hardening alloy steel powder, Japan Hitachi SKD61, domestic SACM645 domestic 38CrMoALA alloy steel, alloy steel, tungsten steel, 45# steel, H13 and other materials. Glue head ring meson role: glue head group in the plastic injection molding process of plastic melt mixing, molten plastic mixing, glue head defines a role distance.

- Q: How much is a new injection molding machine, mainly mobile phone shell?

- Mobile phone shell should be used Demag, German machine is very stable. 80t to more than 200 thousand Oh, very expensive

- Q: What factories in Shenzhen area have injection molding machines? What's the number?

- Shenzhen grand Electromechanical Technology Co., Ltd., all electric injection molding machine, energy saving, environmental protection, precision, improve production efficiency.

- Q: What kind of after-sales service, which friends know to introduce?

- The best thing is the company's low pressure injection molding machine, and many famous brands are looking for them to process low voltage injection molding machines, such as apple, Microsoft, and the United states.

Send your message to us

injection molding machine LOG-250S8/A8 QS Certification

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100000 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords