Injection Molding Machine LOG-130S8/A8 QS Certification

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 720 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Condition: New

Type: Preform Injection

Style: Horizontal

Brand Name: LOG MACHINE

Model Number: LOG130-A8

Place of Origin: China (Mainland)

Plastic Type: Thermoplastic

Automatic: Yes

Injection Weight: 196g-239g-277g

Clamping Force: 1300KN

Opening Stroke: 380mm

Power(W): 11 Kw

Certification: CE ISO9001

After-sales Service Provided: Engineers available to service machinery overseas

Voltage: 380V

Name: PET Preform

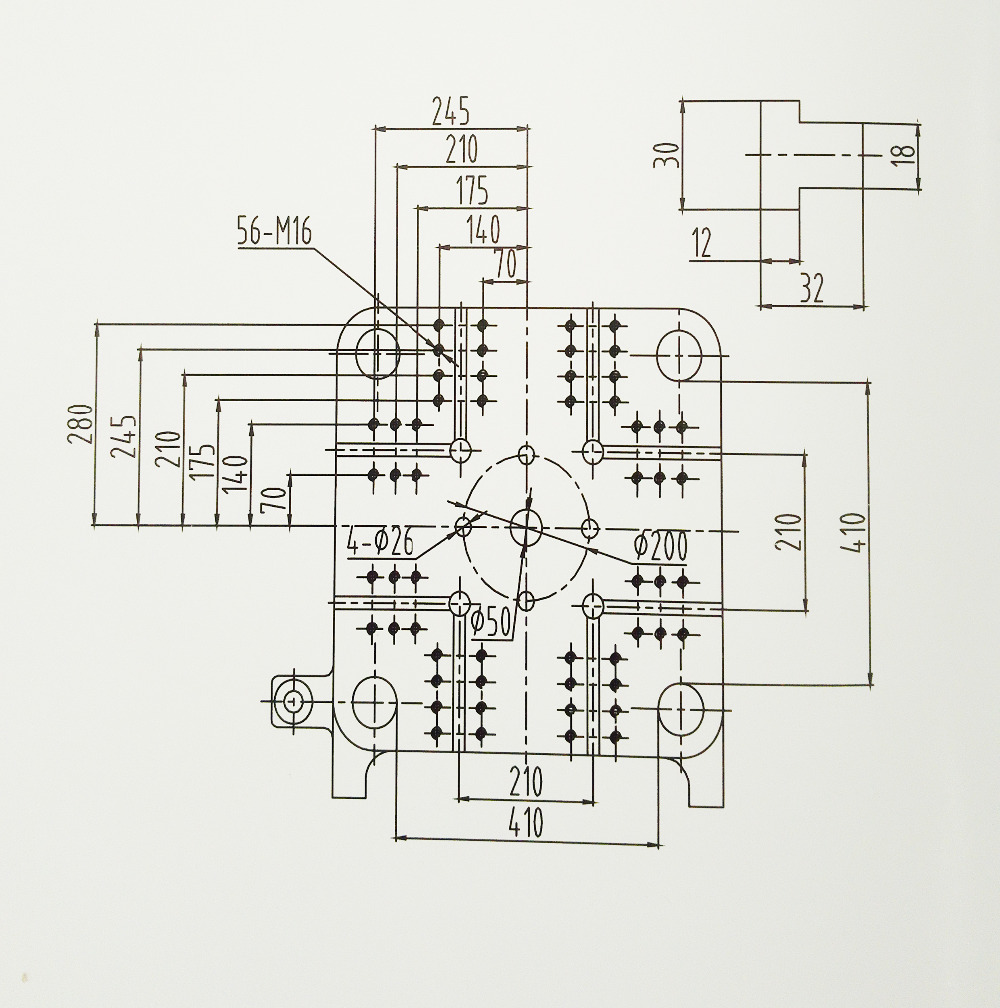

Space between tie bar: 410mm*410mm

Color: Green

Machine weight: 4T

Screw Diameter: 38-45mm

Machine dimension(L*W*H): 4.6*1.2*1.8

Warranty: 1 Year

Material: Stainless Steel

Machine: Thermoplastic Injection Moulding Machine

| Description | Unit | LOG-130A8 | ||

| international recognized models | 416/130 | |||

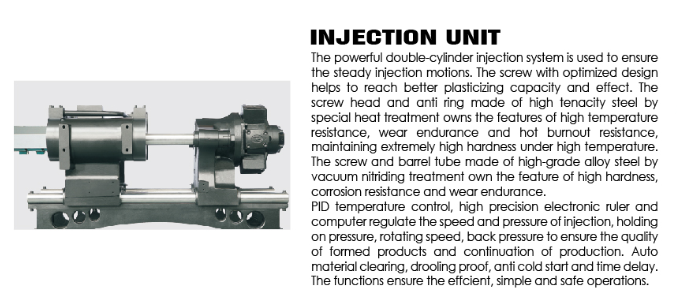

| injection | A | B | C | |

| Tjeoretical injection volume | cm³ | 215 | 263 | 302 |

| Shot volume | g | 196 | 239 | 274 |

| Oz | 6.9 | 8.4 | 9.6 | |

| Screw diameter | mm | 38 | 42 | 45 |

| Injection diameter | mpa | 193 | 158 | 138 |

| Screw L:D ratio | 22:01 | 20:01 | 18:01 | |

| Scerw steoke | mm | 190 | ||

| Screw rotate speed | r/min | 180 | ||

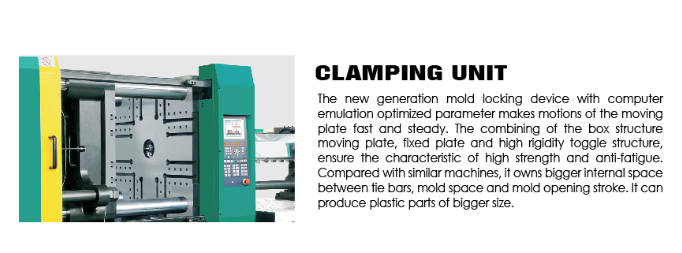

| CLAMPING UNIT | ||||

| Clamping force | kN | 1300 | ||

| Opening stroke | mm | 380 | ||

| Platen size | mm*mm | 610*610 | ||

| Space between tie bars | mm*mm | 410*410 | ||

| Maldthickness | mm | 150-430 | ||

| Platen Mix stroke | mm | 810 | ||

| Ejection stroke | mm | 120 | ||

| Ejcetion force | kN | 42 | ||

| Power/Elcetric Heating | ||||

| Hydralic system pressure | Mpa | 17.5 | ||

| Pump motor | kw | 12 | ||

| Heating power | kw | 7.7 | ||

| Number of temp.conteol | 4+nozzle | |||

| Other | ||||

| Cycle time | sec | 1.3 | ||

| Tank volume | L | 200 | ||

| Machine dimesions | m*m*m | 4.6*1.2*1.8 | ||

| Weight of machine | kg | 4000 | ||

Packaging Details: 20 GPcabinet Delivery

Delivery Detail: two weeks after get payment

| INJECTION | LOG130 | |||

| A | B | C | ||

| Shot volume | cm³ | 215 | 263 | 302 |

| Shot weight (ps) | G | 196 | 239 | 274 |

| oz | 7 | 8 | 10 | |

| Max injection rate | cm³/s | 97 | 118 | 163 |

| Screw diameter | mm | 38 | 42 | 45 |

| Plasticizing rate | Kg/h | 46 | 60 | 75 |

| Injection pressure | Mpa | 193 | 158 | 138 |

| Screw L:D ratio | 22:01 | 20:01 | 18:01 | |

| screw speed | r/min | 0~180 | ||

| CLAMPING | ||||

| Clamping force | Kn | 1300 | ||

| Opening stroke | mm | 380 | ||

| Platen size | mm*mm | 610*610 | ||

| Space between tie bars | mm*mm | 410*410 | ||

| Mold thickness (Min--Max) | mm | 150~430 | ||

| Hydraulic ejection stroke | mm | 120 | ||

| Hydraulic ejection force | Kn | 42 | ||

| Power Unit | ||||

| Hydraulic system pressure | Mpa | 17.5 | ||

| Pump motor | Kw | 11 | ||

| Heating capacity | Kw | 7.7 | ||

| Number of temp control zones | 4+ (nozzle) | |||

| GENERAL | ||||

| Dry-cycle time | sec | 1.3 | ||

| oil tank capacity | L | 200 | ||

| Machine dimensions | m*m*m | 4.6*1.2*1.8 | ||

| Machine weight | kg | 3550 | ||

Platen Dimensions:

product 1

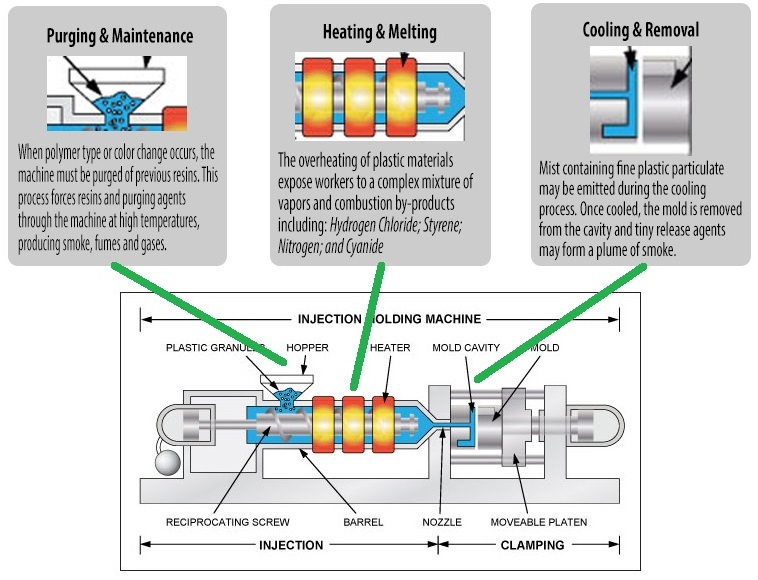

Common thermoplastic resins include:

Polyethylene PE

Polyvinyl Chloride PVC

Polypropylene PP

Polystyrene PS

Polyethlene Terephthalate PET

Acrylonitrile-butadiene-styrene ABS

Styrene-Acrylonitrile SA

Acrylic PMMA

Polyamide PA (Nylon)

Styrene-Acrylonitrile SAN

Polycarbonate PC

- Q: What are the features of servo motors for injection molding machines?

- 1, energy saving2 、 quick response and high production efficiency,3 、 pressure stability precision4, high repeatability, saving material5 、 low temperature rise of oil temperature6, low noise

- Q: Name of China's top ten famous brand injection molding machines

- Sheng Yue, Chen De, Haitian, Shanghai Guangsu, Huada, Glenn, Borch, grand, ACE, Chung East, too, Haitai, energy, Lima, DMX, Acer too, and wide, Hongli, starfish

- Q: What's the difference between an electric injection machine and an oil press?

- Electric injection molding machine is a combination of electronic control and transmission of an integrated device, hydraulic press is only an action of the implementation of the body.The electric injection molding machine is small and easy to move. It is beneficial to the parallel production of many varieties and small quantities. It can save space, save energy, increase production flexibility and reduce the cost of comprehensive production.Electric injection molding machine the power system adopts full motor drive, and PLC, inverter and servo control technology, in order to achieve high precision control and substantial energy saving at the same time, to avoid the common hydraulic injection molding machine noise, heat and oil leakage phenomenon.Electric injection molding machine in injection molding structure, adopts screw plunger hybrid structure and PID temperature control, effectively ensure the stability of plasticizing and metering, from general resin to engineering plastics, injection molding can be of high quality, suitable for various fields of microelectronics, telecommunications, electrical appliances, instruments and automation devices, watches, toys and medical devices such as micro precision injection molding production.Hydraulic machine (a hydraulic machine) is a kind of special hydraulic oil as the working medium, through the hydraulic pump as a power source, by force to pump the hydraulic oil into the cylinder / piston through a hydraulic pipeline, then the cylinder / piston seal in several groups with each other, the different position of the seal is different but, all play a role in sealing, the hydraulic oil can not leak. Finally, through the one-way valve to make hydraulic oil in the tank cycle, so that the cylinder / piston cycle work, so as to complete a certain mechanical action as a productive force of a machine.

- Q: Want to know how to play a complete product, how to calculate the pressure, speed, etc.. Example, GREE electrical appliances series 4002B chassis, how can I transfer the full product?.

- (2) debugging of die closing device;1) wipe the mold clean, then carefully and securely installed between the fixed die, and then adjust the length of the slider according to the size of the plastic block, limiting the opening of the moving template.2) adjust the ejector mechanism so that it can push the molding out of the die cavity to the preset distance.3) the clamping force should be adjusted according to the requirements of the processing technology. The die clamping force should be adjusted to the lower limit of the required clamping force.4) adjust all stroke switches to their respective positions, and adjust the closing of the die.5) adjust the speed and pressure of the mold opening and closing die, generally adjust the speed to the pre selection value, then adjust the pressure to the specified value.6) the clamping device can only work on both sides of the injection machine when the safety door is closed, and check whether the machine will stop working when the safety door is open.

- Q: Mold opening stroke: 1800/1300mmMaximum opening distance of template: 2000 ~ 2500mmWho can help me explain what these two parameters mean? This is a two plate injection molding machine.

- This injection molding machine is quite big! Mold opening stroke: 1800/1300mm refers to the maximum moving stroke of the injection molding machine.The maximum opening distance of the template is 2000 to 2500mm, not the opening distance. It is the maximum distance of the template, that is to say, the largest size of the mold, that is, the maximum shape of the mold.

- Q: How big is the minimum injection molding machine?

- Horizontal injection molding machine is generally the smallest in 40T, vertical minimum is 3T, the amount of injection is 15g, the working voltage is 220V, the power consumption is 0.8kw/h.Injection molding machine, also known as injection molding machine or injection machine. It is a thermoplastic or thermosetting plastic plastic molding mold made of plastic products of all shapes of the main molding equipment. It is divided into vertical, horizontal and all electric type. The injection molding machine heats the plastic, applying high pressure to the molten plastic to make it crack and fill the mold cavity.

- Q: Advantages and disadvantages of horizontal injection molding machines and vertical injection molding machines?

- 1. horizontal machine has the advantages of high operation, convenience, high safety performance, large bearing size and so on. The disadvantage is that the floor space is large and the price is relatively high. Suitable for medium and large moulds.

- Q: Vertical injection molding machine in the semi-automatic state, not sol, and sometimes sol is very slow, seems to be very difficult, and sometimes simply do not turn. The problem is that it occurs during normal use, so the temperature should be fine. The parameter should be OK, too. I removed the screw and cleaned it. There was no foreign object. Under manual operation, the sol is very smooth. Consult an expert.

- I have encountered such a thing, I analyze the vertical machine tonnage is small, PC material excellent, too sticky. If it's ABS, PVC, PBT and other materials, that's OK, right?

- Q: Haitian injection molding machine alarm, hydraulic insurance exception, what are the reasons?

- The problem is on hydraulic oil, such as insufficient hydraulic oil, hydraulic oil containing impurities. Check, either add hydraulic oil, or replace the hydraulic oil.

- Q: How does the steel injection machine go to the origin?

- 3, with the clamping force of 15% of the set, if the spring die can not be completely closed, or want to reduce the mold contact time, in the range of +-10%, adjust the mold low pressure protection pressure. In the setting of clamping stroke, pressure mold protection must be set by the mold temperature reaches the set value can be accurately set a low voltage protection, because in the cold to be better at the mold temperature reaches the set value of thermal expansion is not locked. 6.2 after the set with A4 (40*40MM) A4 with butter wet paste in the mold safety parting surface, and then clamping voltage protection effect test. If after the mold, the machine will alarm, OK, otherwise reset the low voltage protection parameter until OK.This answer is recommended by users

Send your message to us

Injection Molding Machine LOG-130S8/A8 QS Certification

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 720 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords