Injection molding machine LOG-900S8 QS Certification

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100000 unit/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Quick Details

Condition: New

Style: Horizontal

Brand Name: LOG MACHINE

Model Number: LOG 900S8

Place of Origin: China (Mainland)

Plastic Type: Thermoplastic

Automatic: Yes

Clamping Force: 9000kn

Power(W): 37+37

Certification: CE ISO9001

After-sales Service Provided: Engineers available to service machinery overseas

Packaging & Delivery

| Delivery Detail: | 60 DAYS |

|---|

| Description | Unit | LOG-900S8 | |||

| international recognized models | |||||

| injection | B | C | D | ||

| Tjeoretical injection volume | cm³ | 3179 | 3825 | 4750 | 5652 |

| Shot volume | g | 2893 | 3571 | 4321 | 5143 |

| Oz | 102.5 | 12.6 | 153 | 182.1 | |

| Screw diameter | mm | 90 | 100 | 110 | 120 |

| Injection diameter | mpa | 227 | 184 | 152 | 128 |

| Screw L:D ratio | 24.4:1 | 22:01 | 20:01 | 18.3:1 | |

| Scerw steoke | mm | 500 | |||

| Screw rotate speed | r/min | 0-120 | |||

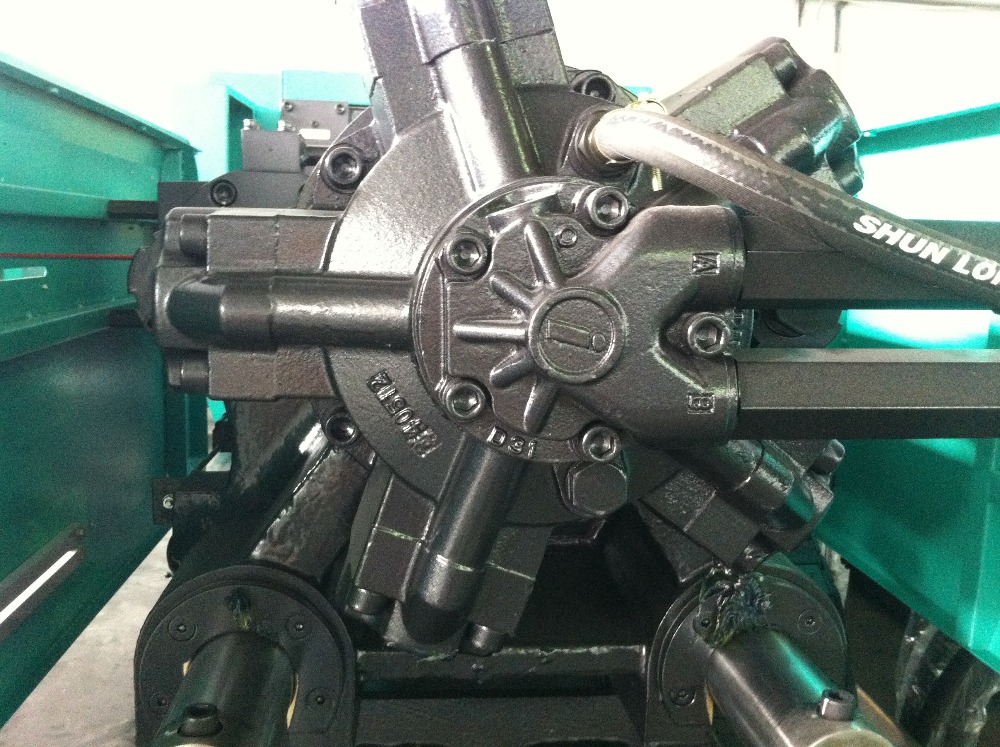

| CLAMPING UNIT | |||||

| Clamping force | kN | 9000 | |||

| Opening stroke | mm | 1050 | |||

| Platen size | mm*mm | 1530*1530 | |||

| Space between tie bars | mm*mm | 1080*1030 | |||

| Maldthickness | mm | 400-1100 | |||

| Platen Mix stroke | mm | 2150 | |||

| Ejection stroke | mm | 300 | |||

| Ejcetion force | kN | 270 | |||

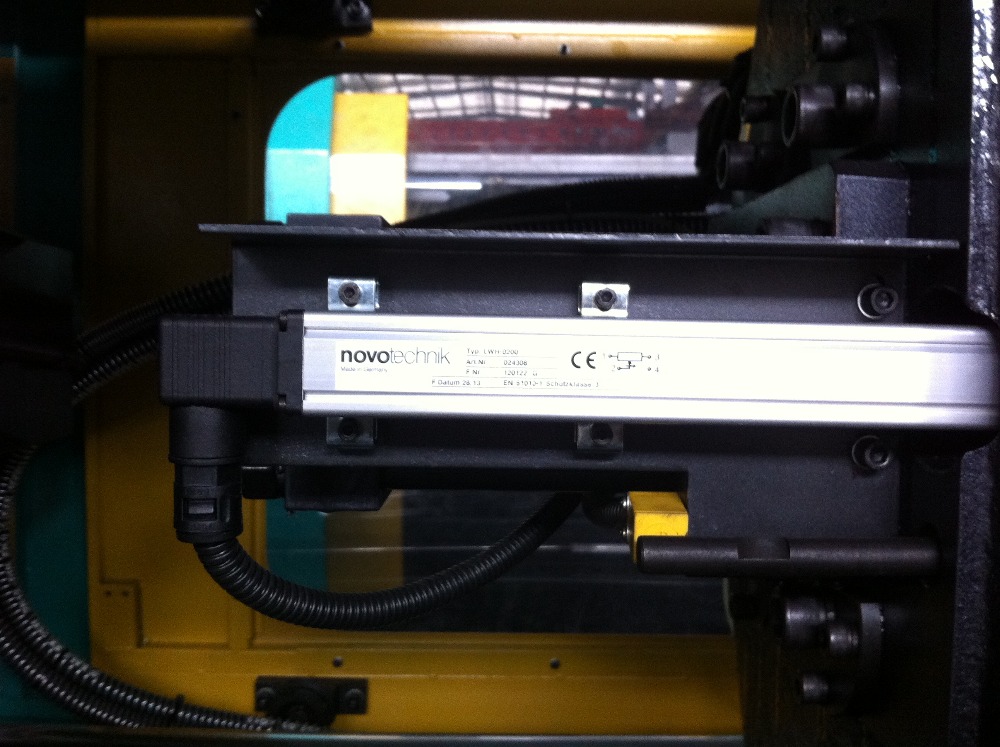

| Power/Elcetric Heating | |||||

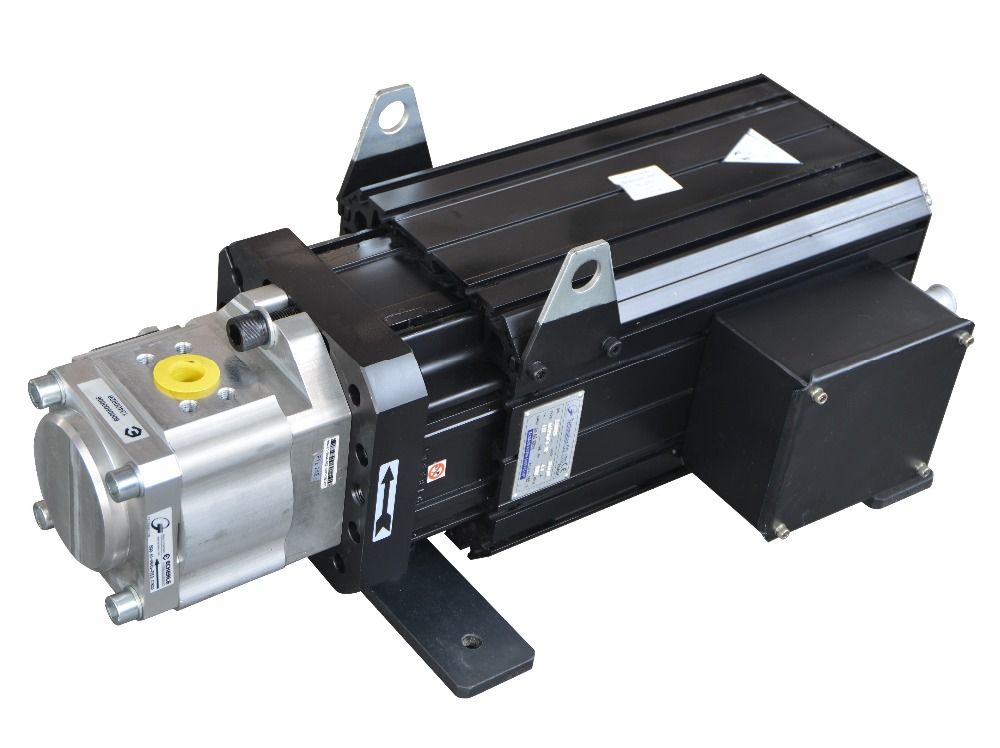

| Hydralic system pressure | Mpa | 17.5 | |||

| Pump motor | kw | 37+37 | |||

| Heating power | kw | 52.45 | |||

| Number of temp.conteol | 6+nozzle | ||||

| Other | |||||

| Cycle time | sec | 8 | |||

| Tank volume | L | 1900 | |||

| Machine dimesions | m*m*m | 11*2.4*3.1 | |||

| Weight of machine | kg | 48000 | |||

- Q: What kinds of lubricants are used in the injection molding machine?

- Imported generally have thimble grease, the machine comes with lubricating oil bag

- Q: How many moulds can the 80 ton injection molding machine put down?

- There are two main decisions: meaning opening distance, and two is the distance between the guide pillars.

- Q: How about the four column balance of injection molding machine?

- With a dial indicator on the two pattern, by adjusting the big nut on the column Corinth to achieve its balance

- Q: Quanlifa injection molding machine can replace the barrel and screw size

- As long as the manufacturer can do, Zhoushan Xin Ren mechanical screw barrel manufacturing experts welcome!

- Q: Introduction of injection molding machine

- Secondly, the rated power of the whole machine is only 245KW, and the energy consumption of the traditional machinery is reduced by more than 45%;Third, an injection molding capacity of more than 50KG, ranking first in the world;Fourth, injection precision control, will not produce bubbles in the injection molding, greatly improving the quality of products;Fifth, the products are widely used in industry, transportation, warehousing, packaging, building, automobile, home appliances and defense, large plastic injection products with its light weight, good elasticity, high impact resistance, good chemical stability and excellent mechanical properties, is widely replaced with steel products and wood products.

- Q: How to choose an injection molding machine

- According to the production of the product, the maximum clamping force, maximum injection volume, maximum injection pressure, output and other auxiliary top ejection hole number and arrangement, the number of neutrons etc.

- Q: How many grams of 200t injection molding machine?

- Each injection molding machine is standard with three types of screw, mainly to see requirements, the smallest less than 200g, the largest more than 300, general ABS with medium-sized screw, PA, PC with small screw, PP with large screw.Energy conservation:The energy saving of injection molding machine can be divided into two parts: one is the power part, and the other is heating part.Energy saving: most of the power inverter, energy saving way is through energy saving more than the actual motor, such as motor power is 50Hz, and you actually need only in the production of 30Hz is sufficient to produce, the extra energy is wasted, the inverter is to change the output power of the motor to achieve the energy-saving effect.

- Q: What is low voltage protection (injection molding machine)?

- Protect the mold. Never press dies during production

- Q: What kind of after-sales service, which friends know to introduce?

- The best thing is the company's low pressure injection molding machine, and many famous brands are looking for them to process low voltage injection molding machines, such as apple, Microsoft, and the United states.

- Q: What does the injection machine do?

- Injection molding is used to produce plastic products

Send your message to us

Injection molding machine LOG-900S8 QS Certification

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100000 unit/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords