Specifications

PP/PE double-screw extrusion line plastic extruder plastic granulator pelletizing extrusion line,plastic extruder,plastic recycle.

PP/PE double-screw extrusion line

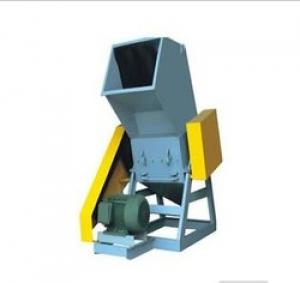

Specialized PP/PE double-screw extrusion line is applied with deep groove swivel, double-mode decelerator, double outside-built

steelbearing seat, equips with auxiliary machine, specified foam crusher and engineering-applied particle cutter. It is applied with hi-rotation

design, combines with friction rapid temperature-rise principle, effectively control decomposition under high temperature ,and lift up particle

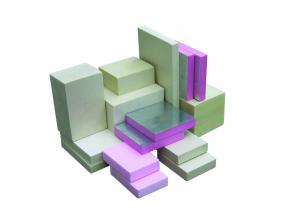

quality and throughput. this machine is widely used to manufacture particle under the strict requirement from EPS,EPE and other super low-

density foaming plastic.