PPGI/GI Corrugated Steel Sheet/Metal Roofing

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 566 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Prepainted Galvanized steel Coil :

With Gi as base metal,after pretreatmet (degrease and chemical treatment) and liquid dope with several Layers of color,then after firing and cooling,finally the plate steel is called pre-painted galvanized steel ( PPGI) .Pre-painted galvanized steel is good capable of decoration ,molding,corrosion resistance

2.Main Features of Prepainted Galvanized steel Coil:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

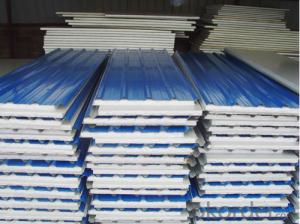

3.Prepainted Galvanized steel Coil Images

4.Prepainted Galvanized steel Coil Specification

Standard:ASTM, GB,JIS,JIS G3302 ASTM 755 EN10169

Grade: DX51D CGCC CS

Thickness: 0.13mm~3.0mm,

Width: 1250,600-1250mm

Coil weight:3-12 MT

Coil ID:508/610mm

Chemical composition:

| product | corrugated metal roofing sheets |

| Brand | CNBM |

| supply ability | 250,000 tons per year |

| base material | galvanized steel sheet |

| thickness | 0.15-0.6mm |

| width | 600-1250mm |

| quality | spcc,dx51d,sgcc,sgch |

| zinc-coating | 60-180g/m2 |

| technique | cold rolled-hot dipped galvanizing- corrugated |

| tolerance | thickness: +/- 0.02mm |

| width: +/-2mm | |

| feature | lowes sheet metal roofing have excellent performance of decoration, corrosion resisitance etc. |

| package | 1. PVC film 2. Anti-water paper. 3. Metal |

5.FAQ of Prepainted Galvanized steel Coi

We have organized several common questions for our clients,may help you sincerely:

1.How do you control your quality

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

2.how long we will receive the goods ?

After receiving your deposit or workable lc ,our normal shipment date is 15-20days,and it takes around 28 days to reach your port of destination. But is up to different destination

3. what is your moq

Normally our moq is 25per size ,but it is up to different size

- Q: What are the different types of steel storage racks?

- There are several different types of steel storage racks, including pallet racks, cantilever racks, push back racks, and drive-in racks. Pallet racks are designed to store palletized goods and are available in different configurations such as selective, double deep, and narrow aisle. Cantilever racks are used for long and bulky items like pipes and lumber. Push back racks are designed for high-density storage and allow for multiple pallets to be stored one behind the other. Drive-in racks are used for storing large quantities of the same product and allow forklifts to drive directly into the racks to retrieve items.

- Q: What are the different types of steel products used in the manufacturing of jewelry and accessories?

- The different types of steel products used in the manufacturing of jewelry and accessories include stainless steel, surgical steel, and carbon steel. Stainless steel is a popular choice due to its durability, resistance to tarnish and corrosion, and affordability. Surgical steel, which is a type of stainless steel, is often used in body jewelry as it is hypoallergenic and safe for people with sensitive skin. Carbon steel, on the other hand, is less commonly used in jewelry but can be found in certain accessories for its strength and unique aesthetic qualities.

- Q: What are the applications of steel mesh in architectural facades?

- Steel mesh has various applications in architectural facades. It is commonly used as a cladding material to provide both aesthetics and functionality. Steel mesh can be used to create visually appealing designs on the exterior of buildings, adding texture and depth. Additionally, it can be utilized as a sunshade or privacy screen, allowing for controlled light and ventilation while maintaining privacy. The durability and strength of steel mesh also make it suitable for enhancing the structural integrity of facades. Overall, steel mesh offers versatility and practicality, making it a popular choice in architectural facades.

- Q: How is steel used in the production of pipelines?

- Steel is commonly used in the production of pipelines due to its strength, durability, and resistance to corrosion. It is used to construct the main body of the pipeline, providing a sturdy structure to transport various types of fluids over long distances. Additionally, steel pipes can be welded together, allowing for easy installation and maintenance.

- Q: How are steel pipes used in oil and gas pipelines?

- Steel pipes are used in oil and gas pipelines due to their strength, durability, and resistance to harsh conditions. These pipes are used to transport crude oil, natural gas, and other petroleum products over long distances. They are able to withstand high pressure and temperature variations, ensuring the safe and efficient transportation of these resources. Additionally, steel pipes are often coated with protective layers to prevent corrosion and ensure the longevity of the pipeline system.

- Q: What are the common uses of steel in the defense industry?

- Steel is commonly used in the defense industry for a variety of applications such as manufacturing armored vehicles, naval ships, aircraft carriers, submarines, and tanks. It is also utilized for constructing military infrastructure, including bunkers, fortifications, and military base facilities. Furthermore, steel is essential for producing weapons, ammunition, and equipment for the armed forces. Its high strength, durability, and resistance to impact make it an ideal material for ensuring the safety and effectiveness of defense operations.

- Q: How does the price of steel products vary based on their composition and quality?

- The price of steel products varies based on their composition and quality due to several factors. First, the composition of steel, including the presence of various elements such as carbon, alloying elements, and impurities, significantly affects its properties and performance. Steel with higher carbon content or specific alloying elements can have enhanced strength, durability, and resistance to corrosion, making it more expensive. Second, the quality of steel, which encompasses factors like manufacturing processes, heat treatment, and craftsmanship, also impacts its price. Higher quality steel products undergo more stringent production techniques, resulting in better performance and higher cost. Additionally, the market demand and availability of specific steel compositions and grades also influence their prices. Overall, the price of steel products varies based on their composition and quality, with higher quality and specialized compositions generally commanding a higher price.

- Q: What are the different types of steel valves and their uses?

- There are several types of steel valves, including gate valves, globe valves, ball valves, butterfly valves, and check valves. - Gate valves are primarily used to control the flow of liquids or gases and are commonly found in plumbing systems. - Globe valves are designed for regulating the flow of fluids and are often used in industries such as oil and gas, power plants, and water treatment plants. - Ball valves have a spherical disc that controls the flow of fluids and are suitable for applications that require quick shut-off or precise control. - Butterfly valves have a disc that rotates to control the flow of fluids and are widely used in industries like HVAC, water treatment, and chemical processing. - Check valves allow the flow of fluids in one direction and prevent backflow, making them useful in applications where preventing reverse flow is crucial. These valves can be made of various types of steel, such as carbon steel, stainless steel, or alloy steel, depending on the specific requirements of the application.

- Q: What are the different types of steel fasteners and connectors available?

- There are several types of steel fasteners and connectors available, including screws, bolts, nuts, washers, rivets, and nails. Each type serves a specific purpose and is designed to provide a secure and reliable connection in various applications.

- Q: What are the different types of steel wire ropes and their uses in offshore drilling operations?

- There are several types of steel wire ropes commonly used in offshore drilling operations. These include drilling lines, sandline cables, and guy wires. Drilling lines are heavy-duty wire ropes designed to support the weight of the drill string and transport drilling fluids. They are used to lower and raise the drill bit, as well as to rotate the drill string during drilling operations. Sandline cables, on the other hand, are lighter wire ropes used for well servicing and workover operations. They are primarily used to lower and retrieve equipment, such as pumps and tools, into and out of the wellbore. Lastly, guy wires are steel wire ropes used to support and stabilize offshore drilling platforms or structures. They help to counterbalance the weight and forces acting on the structure, ensuring stability and safety. Overall, steel wire ropes play a crucial role in offshore drilling operations, providing strength, durability, and reliability necessary for various tasks and applications.

Send your message to us

PPGI/GI Corrugated Steel Sheet/Metal Roofing

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 566 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords