Corrugated Roofing Sheet Color Coated Steel Coil PPGI

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Corrugated Roofing Sheet/Color Coated Steel Coil/ppgi

1.Application

Construction | Outside | Workshop, agricultural warehouse, roof panel, wall panel in steel structure in warehouse,corrugated roof, roller shutter door, rainwater drainage pipe, retailer booth |

| Inside | factories exhibition hall,doorcase, light steel roof structure, folding screen, elevator, stairway | |

Electrical appliance | Refrigerator, washer, switch cabinet, instrument cabinet, air conditioning, micro-wave oven, bread maker | |

Furniture | Central heating slice, lampshade, chifforobe, desk, bed, locker, bookshelf | |

Carrying trade | Exterior decoration of auto and train, clapboard, container, isolation lairage, isolation board | |

Others | Writing panel, garbage can, billboard, timekeeper, typewriter, instrument panel, weight sensor, photographic equipment | |

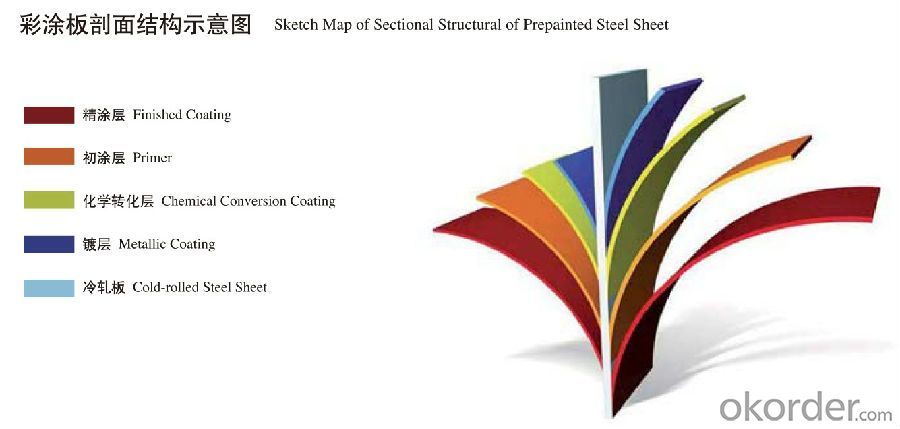

2.Features

With excellent cold-rolling steel strips as base material, it has the advantages of

* Good manufacturing performance

* High impact resistance

* Uniform plating thickness

* High adhesive force

* No peeling after forming

* High corrosion resistance

3.Product Details

Base Material | Al-Zn Galvanized Steel Coil.SGLCC |

Top Side | 15-25 microns |

Back Side | 5-8 microns |

Width | 700-1250mm |

Thickness | 0.3-1.0mm ,thickness tolerance: +/- 0.02mm |

Al-Zn Coating | 30-150g/sq.m |

Spangle | Regular/Zero/Big |

Color | All RAL Color,or be customized |

Coil ID | 508mm&610mm |

4. Image:

5. Production Line

6.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your Warranty?

Warranty: 1-Year for the whole light. Warranty is based on correct storage, installation, using and maintenanc

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: I was just thinking, is their a way to make steel qualities inherent in concrete, therefore eliminating the need for re bar?

- There is an iron powder reinforced concrete flooring that improves abrasion resistance. However, you cannot get the tensile strength enhancement that is possible with rebar.

- Q: How are steel coils used in the manufacturing of storage systems?

- Due to their durability, strength, and versatility, steel coils are an indispensable element in the production of storage systems. Typically made from high-quality steel, these coils are formed by rolling the steel into a coil shape. Within the manufacturing process of storage systems, steel coils serve multiple functions. Primarily, they are utilized in the construction of shelves, racks, and frames. These components offer the necessary structural support to hold and arrange items within the storage system. The robustness of the steel coils guarantees that the storage system can endure heavy loads and maintain stability over time. Furthermore, steel coils are employed in the fabrication of accessories for storage systems, such as brackets, hooks, and dividers. These accessories provide additional functionality and customization options, enabling users to optimize their storage space according to their specific requirements. Moreover, steel coils often serve as the material for doors and panels in storage systems. These coils are molded and shaped to create sturdy and secure doors that offer convenient access to the stored items while maintaining the overall integrity of the system. These doors can be designed with various locking mechanisms to enhance security and prevent unauthorized access. Additionally, steel coils are crucial in the production of mobile storage systems. These systems, such as mobile shelving units or compactors, are designed to maximize storage capacity in limited space. The flexibility and versatility of steel coils allow for the creation of movable components that can be easily adjusted and reconfigured to accommodate changing storage requirements. In summary, steel coils play a vital role in the manufacturing of storage systems, providing the necessary strength, durability, and versatility required for these structures. Whether utilized for shelves, accessories, doors, or mobile systems, steel coils ensure that storage systems are reliable, secure, and efficient in organizing and storing various items.

- Q: Where can you buy a steel polearm in a shop or if someone has a file in Scania than can you sell me one ill buy it for 150k my account is tonypark500

- you can buy it at the free market, but they worth more than 150k they sell for about 1m so good luck with getting polearm.

- Q: what is the stucture of high carbon steel

- I dont know percentages just that it is basic steel with added carbon it is used for tooling and other reasons that need a steel that can be hardened ~~

- Q: What are the different types of surface finishes for steel coils?

- There are several different types of surface finishes for steel coils, each offering its own unique properties and advantages. Some of the most common surface finishes for steel coils include: 1. Hot Rolled: This is the most basic surface finish for steel coils and is achieved by heating the steel and then rolling it to its final shape. It typically has a rough and scale-like appearance, with varying levels of surface imperfections. 2. Cold Rolled: This surface finish is achieved by further processing hot rolled steel coils through a series of cold rolling operations. Cold rolled steel has a smoother and more uniform surface compared to hot rolled steel, with improved dimensional accuracy and better surface quality. 3. Galvanized: Galvanizing is a process in which a protective layer of zinc is applied to the surface of the steel coil. This surface finish provides excellent corrosion resistance, making it ideal for outdoor applications and environments where the steel is exposed to moisture and other corrosive elements. 4. Stainless Steel: Stainless steel coils have a unique surface finish due to the presence of chromium, which forms a thin, invisible layer of oxide on the surface. This surface finish provides excellent corrosion resistance and a visually appealing appearance. 5. Electrolytically Zinc Coated: Also known as electrogalvanized, this surface finish involves the application of a thin layer of zinc to the steel coil through an electroplating process. It provides good corrosion resistance and is commonly used in applications where aesthetics are important. 6. Pre-painted: Pre-painted steel coils have a surface finish that is coated with a layer of paint or other protective coatings. This finish offers both corrosion resistance and aesthetic appeal, allowing for a wide range of colors and finishes to be applied. 7. Aluminized: Aluminized steel coils have a surface finish that is coated with a layer of aluminum-silicon alloy. This finish provides excellent heat resistance and is commonly used in applications where high temperatures are encountered, such as exhaust systems or ovens. Overall, the choice of surface finish for steel coils depends on the specific requirements of the application, including factors such as corrosion resistance, aesthetics, durability, and heat resistance.

- Q: I saw a 27 sedan and a 27 Pick-up one had wood wheels the other steel, respectively. Witch one was original or were they both original

- Steel wheels were not available on the pickups until 1929. The cars had the options of steel disc or wood spoke wheels in the mid '20's. I'm pretty sure that '27 was the last year the wood wheels were available on passenger cars.

- Q: I was curious to what type of steel I should get if I wanted something that kept its edge longer than 154cm but is still just as stainless. I don't know much about knife steels inform me please?

- 154cm is a very good knife steel, the problem is in the heat treating. Stainless should be cryo treated to get all it can offer. That being said, if you really want to drop some coin, look at getting one made from CPM 440V. Stainless isn't as strong as carbon but on a smaller knife works well. You might also look for D-2 Tool steel. There are factory knives that are made of that.

- Q: How do steel coils contribute to energy efficiency in lighting?

- The energy efficiency of lighting relies heavily on the type of light source chosen, such as incandescent, fluorescent, LED, or halogen bulbs. Each of these light sources consumes energy differently. On the other hand, steel coils serve a different purpose in lighting fixtures. Their main function is to provide structural support, dissipate heat, and protect the components. They do not have a direct impact on the energy efficiency of the lighting system. However, steel coils can indirectly improve energy efficiency by offering sturdy support to the fixtures. This ensures that the installations are reliable and long-lasting, reducing the need for frequent maintenance and replacements. A well-supported lighting system guarantees optimal performance and minimizes energy wastage or inefficiencies caused by loose or unstable fixtures. Furthermore, steel coils can also be used to manufacture reflectors or housings for lighting fixtures. These components play a role in enhancing the overall efficiency and distribution of light. By effectively reflecting and directing the light output, energy utilization and illumination can be optimized, resulting in reduced energy waste. Although steel coils themselves do not directly influence the energy efficiency of lighting, their incorporation in the construction and support of lighting fixtures indirectly contributes to a more energy-efficient lighting system.

- Q: case hardening steel is adviced or thru hardening steel is most suitable?

- I don't know your application, but here is some advice. Case hard provides a hard shell around soft steel, depending on the bake, the case is usually .002-.008 thick. (thousands of an inch) Heat treated steel or tool steel is hard all the way thru. Case hardening, provides toughness with flexibility, however, once it's compromised, the part is scrap. Hardend tool steel is extreemly hard throughout and the harder it is, the more brittle it becomes. The application of the part will help you to determine the material needed. For instance; Plastic injection molds are very hard so the hot plastic wont erode them over years of use. Punch Press dies aren't as hard but are tougher to withstand the shock. Machine bolts are case hardened so they can last, but soft enough to allow some stretching during tightening. Either way, the time in mfg will be about the same. Most tool steels today cut like cheese, but take time to be heat treated. Tool steel will cost a bit more than low carbon steel. Low carbon steel is as machinable, and cheaper, but, again, the baking period is as long or longer than tool steel. There are a lot of materials on the market today that maintain the durability of heatreated steel without having to go thru that process. 4140, ( or chrome/moly) comes to mind. There are also some 400 series stainless that work as well, and others. You need to determine strength, flexibility, ease of mfg, cost and repairability when considering which steel to use.

- Q: Is a steel plate the same as a steel coil?

- Generally speaking, they can be used interchangeably, and the purchase price of the plate is slightly cheaper.

Send your message to us

Corrugated Roofing Sheet Color Coated Steel Coil PPGI

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords