Desinged Color Coated Steel Coil PPGI Sheet in Coil for Roofing Building

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

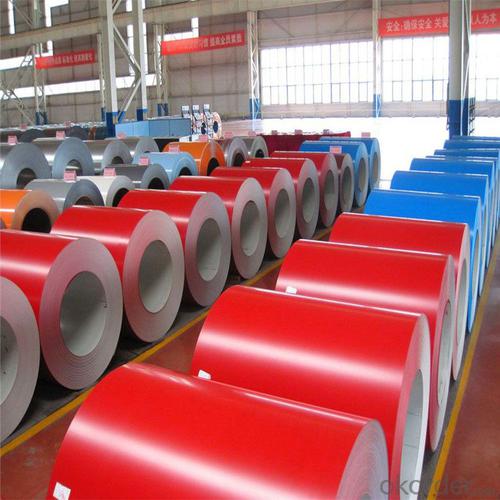

Desinged Color Coated Steel Coil PPGI Sheet in Coil for Roofing Building

Description of Desinged Color Coated Steel Coil PPGI Sheet in Coil for Roofing Building

Product | PPGI/PPGL |

Capacity | 5,000 tons/month |

Base material | Hot dipped galvanized steel |

Thickness | 0.2-2.0mm |

Width | 600-1250mm(according to your need) |

Coil Weight | 3-6tons |

Quality | SGCC, DX51D |

Color | RAL No. or customers samples’ color |

Zinc-coating | 30g/m2-180g/m2 |

Coil ID | 508mm/610mm |

Technique | Cold rolled—hot dipped galvanized—color coated |

Painting | Top painting:15~25μm |

Back painting: 6~10μm | |

Tolerance | Thickness: +/-0.02mm |

Width:+/-2mm | |

Shipment time | within 15-45 workdays |

Payment | T/T, L/C at sight |

Packing | Standard export packing |

The special order can be negotiated. | |

Application of Desinged Color Coated Steel Coil PPGI Sheet in Coil for Roofing Building

APPLICATION OF OUR PREPAINTED STEEL | ||||||||||

Construction | Outside | Workshop,agricultural warehouse,residential precast unit | ||||||||

corrugated roof,roller shutter door,rainwater drainage pipe,retailer booth | ||||||||||

Inside | Door,doorcase,light steel roof stucture,folding screen,elevator,stairway,ven gutter,Construction Wall | |||||||||

Electrical applicance | Refrigerator,washer,switch cabnet,instrument cabinet,air conditioning,micro-wave owen,bread maker | |||||||||

Fuiniture | Central heating slice,lampshade,chifforobe,desk,bed,locker,bookself | |||||||||

Carrying trade | Exterior decoration of auto and train,clapboard,container,isolation lairage,isolation board | |||||||||

Qthers | Writing panel,garbagecan,billboard,timekeeper,typewriter,instrument panel,weight sensor,photographic equipment | |||||||||

Products Show of Desinged Color Coated Steel Coil PPGI Sheet in Coil for Roofing Building

Product Advantages

1.With nearly 20 years experience in prepainted steel, accommodate different marketdemands. | ||||||||||||||

2.'Quality first, service first' is our business aim; 'The good faith get respect,cast quality market' is our Business philosophy . | ||||||||||||||

3.Having two series producttion line,with the abbual production capacity of 240000 tons. | ||||||||||||||

4.Exceed International ISO9001:2008&ISO14001:2004 quality and environmental standards | ||||||||||||||

5.Meet with ROHS standard |

Company Information

CNBM International Corporation is the most important trading platform of CNBM group.

Whith its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high qulity series of refractories as well as technical consultancies and logistics solutions.

F A Q

1, Your advantages?

professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposale

2, Test & Certificate?

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem

3, Factory or Trading Company?

CNBM is a trading company but we have so many protocol factories and CNBM works as a trading department of these factories. Also CNBM is the holding company of many factories.

4, Payment Terms?

30% TT as deposit and 70% before delivery.

Irrevocable L/C at sight.

5, Trading Terms?

EXW, FOB, CIF, FFR, CNF

6, After-sale Service?

CNBM provides the services and support you need for every step of our cooperation. We're the business partner you can trust.

For any problem, please kindly contact us at any your convenient time.

We'll reply you in our first priority within 24 hours.

- Q: How does special steel contribute to the renewable energy industry?

- Special steel plays a crucial role in the renewable energy industry by providing the necessary strength, durability, and resistance to extreme conditions for various applications. It is used in wind turbines, solar panels, and hydroelectric infrastructure, enabling the efficient and reliable generation of renewable energy. Special steel also helps enhance the performance, efficiency, and lifespan of these renewable energy systems, ultimately contributing to the sustainability and growth of the industry.

- Q: How does special steel perform in abrasive wear conditions?

- Special steel is specifically designed to perform exceptionally well in abrasive wear conditions. Its unique composition and manufacturing process make it highly resistant to the detrimental effects of abrasion. The presence of alloying elements such as chromium, manganese, and molybdenum in special steel significantly enhances its hardness and toughness. These elements help to form carbides within the steel matrix, which act as barriers against abrasion. The carbides effectively resist the forces exerted by abrasive particles, preventing them from causing significant damage to the steel surface. Furthermore, special steel undergoes specialized heat treatment processes such as quenching and tempering, which further enhance its resistance to abrasive wear. These processes not only increase the hardness of the steel but also improve its overall toughness and durability. As a result, special steel is capable of withstanding high levels of abrasion without experiencing significant wear or deterioration. In addition to its exceptional mechanical properties, special steel also exhibits excellent corrosion resistance. This is achieved through the addition of elements such as chromium, which forms a protective oxide layer on the steel surface. This oxide layer acts as a barrier, preventing corrosive substances from reaching the underlying steel and causing further damage. Overall, special steel performs exceptionally well in abrasive wear conditions. Its unique composition, heat treatment processes, and corrosion resistance properties make it an ideal material for applications where abrasion is a major concern. Whether in mining, manufacturing, or other industries where abrasive wear is prevalent, special steel can provide superior performance and extended lifespan, ensuring optimal efficiency and cost-effectiveness.

- Q: How is special steel heat treated?

- Special steel is heat treated through a process known as quenching and tempering. Initially, the steel is heated to a specific temperature and then rapidly cooled by quenching in a liquid medium such as oil or water. This rapid cooling helps to harden the steel. Subsequently, the steel is reheated to a lower temperature and held there for a certain period of time to relieve internal stress and improve toughness. This two-step process of quenching and tempering enhances the strength, hardness, and durability of special steel for various applications.

- Q: What are the applications of special steel in the automotive supply chain?

- Special steel has various applications in the automotive supply chain. It is commonly used in the production of critical components such as engine parts, axles, gears, and suspension systems. Special steel provides high strength, durability, and corrosion resistance, contributing to improved performance and safety in vehicles. Additionally, it enables weight reduction, enhancing fuel efficiency and reducing emissions. Overall, special steel plays a crucial role in enhancing the reliability, efficiency, and sustainability of the automotive industry.

- Q: How does special steel perform in surface hardening applications?

- Special steel is renowned for its exceptional performance in surface hardening applications, as it possesses certain desirable properties such as high strength, toughness, and resistance to corrosion and heat. Unlike regular steel, special steel exhibits superior characteristics when it comes to surface hardening. This is due to the presence of alloying elements like chromium, molybdenum, and vanadium, which enhance its hardenability and allow for effective heat treatment processes such as carburizing, nitriding, or induction hardening. These processes alter the microstructure of the steel surface, resulting in increased hardness and wear resistance. What sets special steel apart is its ability to be hardened to a greater depth compared to regular steel. This quality makes it an ideal choice for surface hardening applications, as the hardened layer provides protection against abrasion, erosion, and fatigue, significantly prolonging the lifespan of the component. Moreover, the improved wear resistance and hardness of special steel make it suitable for industries such as automotive, aerospace, and manufacturing, where components are subjected to extreme conditions and high levels of stress. Furthermore, even after surface hardening, special steel retains its exceptional mechanical properties, ensuring durability and the ability to withstand heavy loads and impacts without failure. This combination of hardness and toughness is crucial for applications where both wear resistance and structural integrity are vital. In conclusion, special steel is highly effective in surface hardening applications due to its superior hardenability, wear resistance, and mechanical properties. Its ability to endure extreme conditions while maintaining durability makes it the preferred choice for industries that require components with enhanced surface hardness and longevity.

- Q: What are the different methods of surface passivation for special steel?

- Surface passivation methods for special steel vary in order to enhance its corrosion resistance and overall performance. One popular approach is chemical passivation, where a protective coating is applied to the steel's surface. This coating, composed of substances like chromium oxide or nitric acid, is typically formed through a chemical reaction that creates a protective layer. Chemical passivation is commonly used in industries where the steel is exposed to corrosive environments, such as marine or chemical applications. Another method is mechanical passivation, which involves physically altering the steel's surface to create a protective barrier. This can be achieved through techniques like shot peening or sandblasting, which create a roughened surface that is less prone to corrosion. Mechanical passivation is often employed in situations where the steel is exposed to abrasive or erosive conditions, such as mining or oil drilling. Electrochemical passivation is yet another technique used to passivate special steel surfaces. It entails using an electric current to generate a protective oxide layer on the steel's surface. Processes like electrochemical polishing or anodizing achieve this controlled oxidation. Electrochemical passivation is frequently utilized in industries where the steel is subjected to high temperatures or aggressive chemical environments. Additionally, specialized surface treatments, like plasma or laser surface passivation, are available for special steel. These methods utilize concentrated energy sources to modify the steel's surface and create a protective layer that enhances its corrosion resistance and mechanical properties. Such treatments are typically applied in high-performance applications, such as the aerospace or automotive industries. Ultimately, the choice of surface passivation method for special steel depends on the specific requirements of the application and the desired performance characteristics of the material. Each method has its own advantages and limitations, and factors like cost, time, and environmental impact should be considered when selecting the most suitable method for a particular application.

- Q: What are the different methods for quenching special steel?

- Quenching is a critical step in the heat treatment process of special steel, as it helps to achieve the desired mechanical properties and improve the material's hardness and strength. There are several methods for quenching special steel, each with its own advantages and considerations. 1. Oil Quenching: This is one of the most commonly used methods for quenching special steel. The steel component is immersed in oil, which acts as a cooling medium. Oil quenching provides a moderate rate of cooling, allowing for controlled and uniform hardening. It is suitable for a wide range of steel grades and can prevent cracking or distortion. 2. Water Quenching: Water quenching is a faster cooling method compared to oil quenching. It provides rapid heat extraction, resulting in higher hardness and strength. However, the high cooling rate can also lead to increased risk of cracking or distortion, especially with thicker sections. Water quenching is commonly used for low-alloy steels and some high-alloy steels. 3. Polymer Quenching: Polymer quenching involves using a specialized polymer solution as the cooling medium. This method provides a controlled cooling rate, offering a balance between the slower oil quenching and faster water quenching. Polymer quenching can be particularly suitable for steels with complex shapes or critical dimensions, as it reduces the risk of distortion and cracking. 4. Air Quenching: Air quenching is a slower cooling method that involves allowing the steel component to cool in ambient air. It is typically used for steels with lower hardenability, as it provides a more gradual cooling rate. Air quenching can help to reduce the risk of distortion and cracking, but it may result in lower hardness and strength compared to other quenching methods. 5. Salt Bath Quenching: Salt bath quenching involves immersing the steel component in a molten salt bath as the cooling medium. This method provides a controlled and uniform cooling rate, reducing the risk of distortion and cracking. Salt bath quenching is particularly suitable for complex-shaped or delicate parts, as it minimizes the thermal stress during cooling. It is important to note that the choice of quenching method depends on various factors, such as the steel grade, desired hardness, component size and shape, and the required mechanical properties. Proper selection and implementation of the quenching method are crucial to achieving the desired material characteristics and ensuring the overall quality of the special steel product.

- Q: How does bearing steel contribute to the manufacturing of bearings?

- Bearing steel is a crucial material in the manufacturing of bearings as it provides the necessary strength, durability, and wear resistance required for the efficient operation of bearings. The high carbon content in bearing steel enhances its hardness and strength, ensuring that the bearings can withstand heavy loads, high speeds, and extreme operating conditions. Additionally, the unique composition and heat treatment of bearing steel enable it to maintain dimensional stability and minimize friction, leading to improved performance and longer life of the bearings.

- Q: How is special steel protected against corrosion?

- Special steel is protected against corrosion through various methods such as applying a protective coating, using corrosion-resistant alloys, or implementing techniques like passivation and electroplating.

- Q: What are the key differences between special steel and tool steel?

- Special steel and tool steel are both types of steel that have specific characteristics and applications. The key difference between special steel and tool steel lies in their intended use and properties. Special steel is a broad category that includes various types of steel with specialized properties for specific applications. It is often used in industries such as aerospace, automotive, and construction. Special steel may have enhanced strength, corrosion resistance, heat resistance, or other specific properties, depending on its intended application. On the other hand, tool steel is a specific type of special steel that is specifically designed for making tools. It has exceptional hardness, wear resistance, and toughness, which makes it suitable for applications where cutting, shaping, or forming materials is required. Tool steel is commonly used in the manufacturing of tools such as drills, hammers, dies, and molds. In summary, while special steel is a broader category that encompasses various types of steel with specialized properties, tool steel is a specific type of special steel that is specifically formulated for making tools, offering exceptional hardness, wear resistance, and toughness.

Send your message to us

Desinged Color Coated Steel Coil PPGI Sheet in Coil for Roofing Building

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords