Fiberglass Grating Panel Sheet For Various Usage

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20000 kg

- Supply Capability:

- 300000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Descprition for FRP Grating

With dozens of years' hard works, we now have ability to produce a whole series of FRP products, these include: FRP Molded Grating; FRP Pultruded Grating; Phenolic Molded & Pultruded Grating; FRP Pultruded Structural Profiles; FRP Pultruded Handrails; FRP Pultruded Ladders; FRP Flat Sheet; FRP Decking; FRP Stair tread & Nosing and many customs FRP products. The company has been becoming a most reliable FRP products manufacturer with its stable quality, large productivity & prompt delivery, advanced production systems, rich types. Now our products sell well all over the world, especially in North America, European Areas, South Asia and Middle East.

FRP Grating Features

Corrosion and Chemical resistant;Slip-resistant ;High strength-to-weight ratio;Ergonomic ;Low maintenance ;Fire retardant ;Easily fabricated and installed

Other Positive Features or Advantages

1.Electrically and thermally non-conductive

2.Ultra-violet resistant

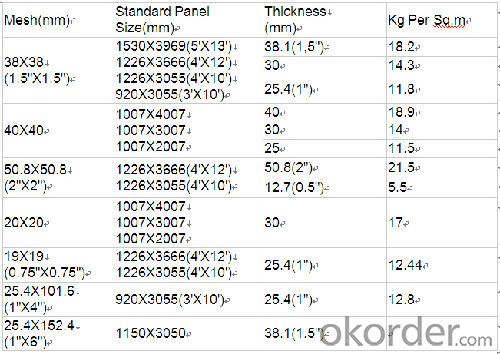

3.Provided in a number of grating thickness and panel sizes with many types of mesh size

4.Offers bi-directional strength characteristic

5.Impact resistance

6.Electronically transparent

Specification

FAQ

1.Which country do you mainly export to?

A: Our products are very popular in Mid East, India, South East Asia, Latin America, Africa.

2.Q: What’s the advantage of you compared with other suppliers experienced in foreign trade?

A: We have been specialized in FRP products for over decades years and approved by many domestic companies. Except for our quality and price, we’re also able to give you the best service.

3.Q:Can you provide some samples?

A: Yes, of course. We will send you samples for your confirmation before you place firm orders.

- Q: Can FRP pultrusion profiles be used in the production of electrical busbars?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in the production of electrical busbars. FRP pultrusion profiles are known for their excellent electrical insulation properties, high strength-to-weight ratio, and corrosion resistance. These characteristics make them suitable for various electrical applications, including busbars. FRP pultrusion profiles offer superior electrical insulation compared to traditional metal busbars, reducing the risk of electrical shock and short circuits. Additionally, their high strength-to-weight ratio allows for the production of lightweight busbars that can handle high electrical currents without sacrificing structural integrity. Furthermore, FRP pultrusion profiles have excellent resistance to corrosion and chemicals, making them ideal for use in harsh environments, such as chemical plants or outdoor installations. They are not susceptible to rust or degradation, ensuring the longevity and reliability of the electrical busbars. Overall, FRP pultrusion profiles provide a cost-effective and efficient solution for the production of electrical busbars, offering enhanced electrical insulation, strength, and corrosion resistance compared to traditional metal alternatives.

- Q: Are FRP pultrusion profiles resistant to caustic soda?

- Yes, FRP (Fiber Reinforced Plastic) pultrusion profiles are typically resistant to caustic soda. Caustic soda, also known as sodium hydroxide, is a strong alkaline substance that can corrode certain materials. However, FRP pultrusion profiles are made of a combination of strong fibers (such as fiberglass) and a resin matrix (such as polyester or epoxy). This composite construction provides excellent resistance to chemicals, including caustic soda. FRP pultrusion profiles are often used in industries where exposure to corrosive substances is common, such as chemical processing, wastewater treatment, and mining. It is important to note that the specific resin used in the FRP profiles and the concentration and temperature of the caustic soda may affect the overall resistance.

- Q: Are FRP pultrusion profiles electrically conductive?

- Typically, FRP pultrusion profiles lack electrical conductivity due to the utilization of a blend of fiberglass reinforcement and a thermosetting resin matrix. These components offer exceptional insulation qualities. The inherent non-conductive nature of the fiberglass reinforcement is further amplified by the resin matrix. Consequently, FRP pultrusion profiles find frequent application in situations where electrical conductivity is undesirable or poses safety hazards. Nevertheless, it is noteworthy that specific modifications or additions can be implemented during the pultrusion process to introduce electrical conductivity, if needed for particular applications.

- Q: Are FRP pultrusion profiles impact resistant?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles are known for their high impact resistance. The combination of strong reinforcing fibers and a polymer matrix makes them highly durable and able to withstand significant impact forces without breaking or deforming.

- Q: Can FRP pultrusion profiles be used in the automotive manufacturing industry?

- Yes, FRP pultrusion profiles can be used in the automotive manufacturing industry. They offer several advantages such as high strength-to-weight ratio, corrosion resistance, and design flexibility. These profiles can be used in various automotive applications including body panels, structural components, and interior trim.

- Q: How do FRP pultrusion profiles perform in high humidity environments?

- FRP pultrusion profiles excel in environments with high humidity due to their exceptional performance. The inherent qualities of FRP, such as its resistance to corrosion and moisture, make it an ideal material for applications exposed to moisture or high levels of humidity. One major advantage of FRP pultrusion profiles is their non-porous nature, which means they do not absorb moisture. This characteristic prevents the profiles from swelling, warping, or deteriorating when exposed to high humidity. Unlike traditional materials like wood or steel, FRP does not degrade or lose its structural integrity in humid conditions. Furthermore, FRP pultrusion profiles have a high resistance to chemicals, including the corrosive effects of moisture and humidity. This corrosion resistance is a result of the composite nature of FRP, which combines a matrix material (typically a resin) with reinforcing fibers, such as glass or carbon fibers. This combination provides excellent resistance to water and moisture-induced corrosion, ensuring the long-term performance of FRP profiles in high humidity environments. Moreover, FRP pultrusion profiles exhibit excellent dimensional stability, even under extreme variations in temperature and humidity. They do not significantly expand or contract, maintaining their shape and structural integrity in diverse environmental conditions. This stability makes FRP profiles suitable for applications in coastal regions, wastewater treatment plants, chemical processing plants, and other environments with high humidity levels. In conclusion, FRP pultrusion profiles are specifically designed to withstand harsh conditions, including high humidity environments. Their non-porous nature, corrosion resistance, and dimensional stability make them a dependable and durable choice for various applications in humid climates.

- Q: Are FRP pultrusion profiles resistant to corrosion and chemicals?

- FRP pultrusion profiles possess exceptional resistance against corrosion and chemicals. Comprising a combination of reinforcing fibers, such as fiberglass, and a polymer resin matrix, FRP exhibits unique properties that enable it to withstand a diverse array of corrosive surroundings and chemical substances. The absence of metal components in FRP pultrusion profiles grants them inherent resistance to corrosion. While metals may succumb to rust or deterioration when subjected to moisture, oxygen, or specific chemicals, FRP remains unyielding to such degradation. Consequently, FRP pultrusion profiles prove to be an ideal choice for implementation in industries like chemical processing, wastewater treatment, marine, and oil and gas. Moreover, FRP pultrusion profiles exhibit remarkable resistance to an array of chemicals, including acids, alkalis, solvents, and salts. The polymer resin matrix employed in FRP serves as a protective barrier, preventing chemical infiltration and structural profile deterioration. This steadfastness ensures that FRP pultrusion profiles can endure harsh environments without succumbing to corrosion or material degradation. In conclusion, FRP pultrusion profiles truly exemplify resistance to corrosion and chemicals. Their composition devoid of metallic elements, coupled with the protective polymer resin matrix, renders them highly durable and appropriate for a vast range of applications where corrosion and chemical resistance are of utmost importance.

- Q: Are FRP pultrusion profiles resistant to moisture absorption?

- FRP pultrusion profiles possess remarkable resistance to moisture absorption, primarily due to the composition of the materials used in their construction. These profiles typically consist of a combination of fiberglass and resin, wherein fiberglass is naturally non-porous and impervious to moisture, while the resin is specifically designed to repel moisture. The moisture resistance of FRP profiles is further enhanced by the pultrusion manufacturing process. This process involves pulling the fiberglass and resin through a heated die, ensuring thorough impregnation of the fibers with resin and creating a dense and solid structure. Consequently, the resulting product exhibits exceptional resistance to water penetration and moisture absorption. Additionally, the moisture resistance of FRP pultrusion profiles can be augmented through the application of protective coatings or surface treatments, such as gel coats or UV-resistant finishes. These coatings provide an extra layer of defense against moisture ingress. The superior moisture resistance of FRP pultrusion profiles makes them an ideal choice for applications that involve exposure to water or high humidity, such as marine environments, wastewater treatment plants, or outdoor structures. By preventing issues like rot, rust, or degradation commonly associated with materials like wood or metal, these profiles offer a reliable and durable solution that can endure moisture exposure without compromising their structural integrity or performance.

- Q: Are FRP pultrusion profiles resistant to high-pressure or corrosive fluids?

- Yes, FRP pultrusion profiles are highly resistant to both high-pressure fluids and corrosive fluids. The composition of FRP (Fiber Reinforced Polymer) with its fiberglass reinforcement and resin matrix provides exceptional strength and durability. This makes FRP pultrusion profiles ideal for applications that involve exposure to high-pressure or corrosive fluids, as they can withstand these conditions without compromising their structural integrity.

- Q: Can FRP pultrusion profiles be used in walkway systems?

- Walkway systems can indeed utilize FRP (Fiber Reinforced Polymer) pultrusion profiles. These profiles are renowned for their impressive strength-to-weight ratio, resistance to corrosion, and durability, which makes them an excellent option for various applications, including walkway systems. Due to the lightweight nature of FRP pultrusion profiles, they are easy to handle and install, which ultimately reduces construction time and cost. Moreover, their corrosion resistance ensures that they can endure harsh environmental conditions, such as exposure to moisture, chemicals, and UV radiation, without deteriorating or requiring frequent maintenance. FRP pultrusion profiles can be tailored to meet specific design requirements, enabling the creation of walkway systems with diverse shapes, sizes, and load-bearing capacities. These profiles can be manufactured with anti-slip surfaces or integrated with other safety features to enhance traction and prevent accidents on the walkways. Furthermore, FRP pultrusion profiles possess excellent electrical insulation properties, making them suitable for walkway systems in areas where minimizing electrical conductivity is necessary, such as power plants or electrical substations. All in all, the distinctive properties of FRP pultrusion profiles make them a dependable and versatile material choice for walkway systems. They offer long-lasting performance, low maintenance requirements, and enhanced safety.

Send your message to us

Fiberglass Grating Panel Sheet For Various Usage

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20000 kg

- Supply Capability:

- 300000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords