FRP Pultrusion Profiles Molded Gratings

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m

- Supply Capability:

- 50000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

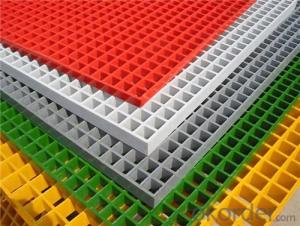

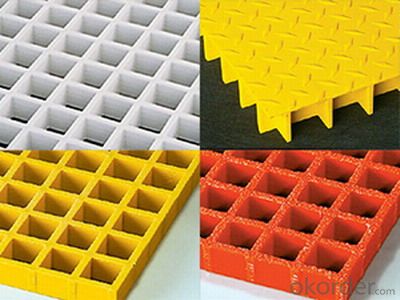

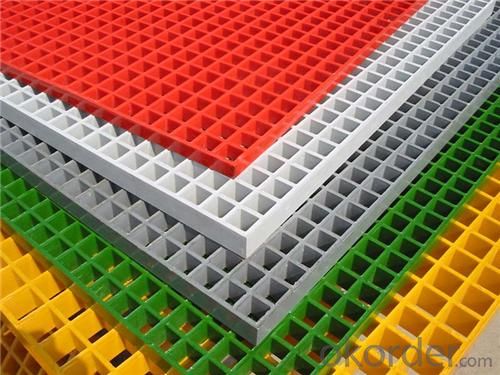

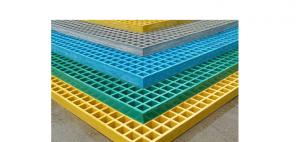

Brief Introduction of FRP Molded Gratings

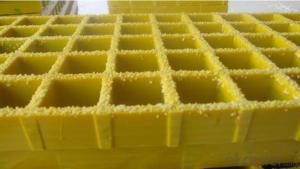

The product is a kind of structural plates which uses high-strength fiberglass roving as reinforcing material, thermosetting resin as the base and then is cast and formed on a special metal mold. It provides properties such as: light in weight, high in strength, corrosion resistance, fire resistance, solid and anti-skid. It is widely used in oil industry, power enrineering, sewage treatment, ocean survey as working floor, stair tread, trench cover, and the . It is an ideal loading frame on corrosion circumstances.

Product Performance of FRP Molded Gratings

1. Corrosion-resistance

2. Fire-resistance

3. Light in weight and high in strength

4. Ageing resistance

5. Designable

6. Safe and anti-skid

7. Insulation

Main Application of FRP Molded Gratings

Operation terrace off-shore oil rig Inspection rack

Stair tread Ground floor

Trench cover

Bridge sidewalk foot bridge

Equipment safety fence

Stair landing

Scaffold filling supporting

Decorating grid

Air grid, etc.

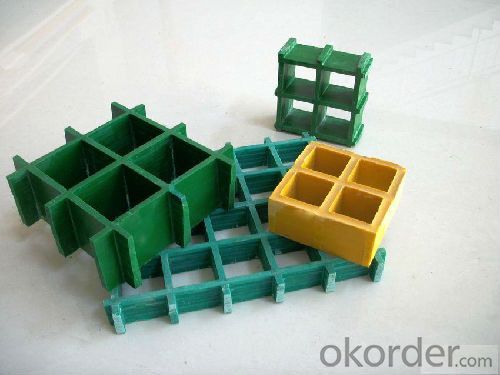

Specification of FRP Molded Gratings

Type | Panel size mm | Lattice size mm | Void ratio | Panel weight Kg |

AS/38.1 x38.1/25.4 | 1220 x 3660 x 25.4 | 38.1*38.1 | 69.9 | 64 |

AS/25.4 x101.6/25.4 | 1220 x 3660 x 25.4 | 25.4 x 101.6 | 63.9 | 73 |

AS/38.1 x38.1/38.1 | 1220 x 3660 x 38.1 | 38.1*38.1 | 70.0 | 92 |

AL/38.1 x38.1/38.1 | 1520 x 3960 x 38.1 | 38.1*38.1 | 70.0 | 114 |

AS/50.8 x50.8/50.8 | 1220 x 3660 x 50.8 | 50.8 x 50.8 | 77.8 | 101 |

AS/38.1 x152.4/38.1 | 1220 x 3660 x 38.1 | 38.1*152.4 | 72.6 | 87 |

AS/38.1 x152.4/38.1 | 579 x 3048 x 38.1 | 38.1 x 152.4 | 74.8 | 34 |

JS/340x40/25 | 1247 x 3087 x 25 | 40 x 40 | 72.3 | 46 |

JS/40 x40/40 | 1247 x 3087 x 40 | 40 x 40 | 72.3 | 73 |

ES/52 x52 /30 | 1000 x 4000 x 30 | 52 x 52 + 19 x 19 | 70.0 | 72 |

ES/52 x52 /50 | 1000 x 4000 x 50 | 52 x 52 + 19 x 19 | 73.3 | 108 |

GS/100 x 100 /25.4 | 117.5 x1480 x25.4 | 100 x 100 | 83.8 | 9 |

FAQ:

1. Why Choose us?

CNBM is a stated owned company, provide the guarantee for the best quality, best service and safety business.

2. How will we guarantee the quality?

a, ISO 9001-2008 quality control system;

b, Strict and regular quality control in production;

c, Inspeciation when loading into container before shippment;

3. Can you provide sample?

- Q: Can FRP pultrusion profiles be used in the construction of stadium seating?

- Yes, FRP pultrusion profiles can be used in the construction of stadium seating. FRP (Fiber Reinforced Polymer) pultrusion profiles offer high strength, durability, and corrosion resistance, making them a suitable choice for stadium seating applications. These profiles can be customized to meet specific design requirements and provide a lightweight alternative to traditional materials like steel or concrete.

- Q: Can FRP profiles replace carbon steel profiles?

- I am a man of glass fiber reinforced material. Honestly, "I can't do it."". Can be used in buildings, such as insulation, corrosion protection, aging resistance, flame retardant, etc.,

- Q: Are FRP pultrusion profiles resistant to fuels?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles are generally resistant to fuels. The combination of high-strength fibers and a polymer matrix makes FRP profiles highly resistant to various chemicals, including fuels. This resistance is primarily due to the non-reactive nature of the polymer matrix, which prevents the fuel from causing any significant degradation or damage to the profiles. FRP pultrusion profiles are commonly used in industries where exposure to fuels is a common occurrence, such as the automotive, aerospace, and oil and gas sectors. These profiles have been extensively tested and proven to withstand prolonged contact with fuels without experiencing any detrimental effects. Additionally, FRP profiles offer several advantages over traditional materials like steel or aluminum in fuel-related applications. They are corrosion-resistant, lightweight, and have excellent dimensional stability, making them ideal for use in environments where the risk of fuel exposure is high. However, it is important to note that the specific resistance of FRP pultrusion profiles to fuels may vary depending on the type and concentration of the fuel, as well as the specific composition of the FRP material. Therefore, it is always recommended to consult with the manufacturer or supplier to ensure that the chosen FRP profiles are suitable for the specific fuel-related application.

- Q: How do FRP pultrusion profiles perform in coastal environments?

- FRP pultrusion profiles are highly durable and perform exceptionally well in coastal environments. The combination of fiberglass reinforcement and resin matrix makes them resistant to corrosion, moisture, and UV radiation, which are prevalent in coastal areas. These profiles have excellent resistance to saltwater, chemicals, and other harsh elements commonly found in coastal environments. Due to their corrosion resistance, FRP pultrusion profiles do not rust or degrade over time, unlike traditional materials such as steel or wood. This durability ensures their long-lasting performance and reduces the need for frequent maintenance or replacement. Furthermore, FRP pultrusion profiles have a high strength-to-weight ratio, making them an ideal choice for coastal applications. They are lightweight yet robust, providing structural stability and reliability in harsh coastal conditions. Their non-conductive nature also eliminates the risk of electrical conductivity, which is crucial in coastal areas where saltwater and humidity can cause electrical corrosion. Another advantage of FRP pultrusion profiles in coastal environments is their ability to withstand extreme temperature variations. They can withstand both hot and cold climates without losing their structural integrity or dimensional stability. This makes them suitable for coastal regions with varying weather conditions. In summary, FRP pultrusion profiles excel in coastal environments due to their corrosion resistance, durability, lightweight nature, and ability to withstand extreme weather conditions. Their performance and longevity make them a reliable choice for various applications such as marine structures, coastal infrastructure, and offshore installations.

- Q: Can FRP pultrusion profiles be used in agricultural applications?

- Indeed, FRP pultrusion profiles are applicable in the field of agriculture. Renowned for their remarkable strength-to-weight ratio, resistance to corrosion, and durability, FRP pultrusion profiles are an ideal choice for a variety of agricultural uses. One common utilization of FRP pultrusion profiles in agriculture is the construction of livestock enclosures, encompassing fences, gates, and pens. These profiles possess outstanding resistance to weather conditions, chemicals, and degradation caused by UV rays, ensuring their long-lasting performance in outdoor environments. Furthermore, their lightweight composition facilitates ease of handling and installation. Moreover, FRP pultrusion profiles find application in the production of agricultural equipment and machinery. They can be employed for structural components, such as beams and supports, as well as functional parts like handles, brackets, and covers. The impressive strength of FRP profiles enables them to withstand heavy loads and challenging operating conditions, while their resistance to corrosion guarantees their longevity in corrosive surroundings such as fertilizer storage areas or livestock waste management systems. Additionally, FRP pultrusion profiles can be utilized for irrigation systems in agriculture. Their non-conductive nature renders them perfect for situations requiring electrical insulation, such as the creation of irrigation pipes or channels. Furthermore, the corrosion resistance of FRP profiles ensures their ability to endure exposure to water, chemicals, and fertilizers frequently employed in agricultural irrigation. To summarize, FRP pultrusion profiles exhibit exceptional suitability for agricultural applications due to their high strength, resistance to corrosion, and durability. Whether employed in livestock enclosures, agricultural machinery, or irrigation systems, FRP profiles offer numerous advantages that position them as a reliable choice within the agricultural industry.

- Q: Are FRP pultrusion profiles resistant to fungal growth?

- Yes, FRP pultrusion profiles are highly resistant to fungal growth. The composite materials used in FRP pultrusion, such as fiberglass and resin, do not provide a suitable environment for fungi to grow. Additionally, the smooth surface of FRP profiles makes it difficult for fungi to attach and thrive. Hence, FRP pultrusion profiles are an excellent choice for applications where resistance to fungal growth is required.

- Q: Are FRP pultrusion profiles resistant to moisture or humidity?

- Yes, FRP pultrusion profiles are highly resistant to moisture and humidity. The combination of fiberglass reinforcement and resin matrix used in their construction makes them non-corrosive and impervious to water absorption. This inherent resistance ensures their durability and performance in humid or moist environments without compromising their structural integrity.

- Q: How do FRP pultrusion profiles perform in high-traffic areas?

- FRP pultrusion profiles perform exceptionally well in high-traffic areas. Due to their inherent strength, durability, and resistance to corrosion, these profiles can withstand heavy loads, constant foot traffic, and various environmental conditions without compromising their structural integrity. Additionally, FRP pultrusion profiles offer excellent electrical insulation properties, making them safe and reliable for use in areas with high human activity.

- Q: Are FRP pultrusion profiles resistant to fungi and mold?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles are generally resistant to fungi and mold. This is due to the non-porous nature of the materials used in their construction, such as fiberglass and epoxy resins. These materials do not provide a suitable environment for fungi and mold to grow, making FRP pultrusion profiles highly resistant to their growth and colonization. Furthermore, FRP pultrusion profiles are inherently moisture-resistant, which is another factor that discourages the growth of fungi and mold. Unlike traditional materials like wood, which can absorb moisture and provide a conducive environment for fungal and mold growth, FRP profiles do not absorb water and are therefore highly resistant to these issues. The combination of non-porous materials and moisture resistance makes FRP pultrusion profiles a suitable choice for applications where fungi and mold resistance is crucial, such as in humid or damp environments. However, it is important to note that no material is entirely immune to fungi and mold growth under all circumstances. In certain extreme conditions, where there is prolonged exposure to high levels of moisture and organic matter, it is still possible for some fungi and mold to colonize FRP profiles. However, compared to other materials, FRP pultrusion profiles offer a significantly higher level of resistance to these issues.

- Q: Can FRP pultrusion profiles be used in walkway systems?

- Walkway systems can indeed utilize FRP (Fiber Reinforced Polymer) pultrusion profiles. These profiles are renowned for their impressive strength-to-weight ratio, resistance to corrosion, and durability, which makes them an excellent option for various applications, including walkway systems. Due to the lightweight nature of FRP pultrusion profiles, they are easy to handle and install, which ultimately reduces construction time and cost. Moreover, their corrosion resistance ensures that they can endure harsh environmental conditions, such as exposure to moisture, chemicals, and UV radiation, without deteriorating or requiring frequent maintenance. FRP pultrusion profiles can be tailored to meet specific design requirements, enabling the creation of walkway systems with diverse shapes, sizes, and load-bearing capacities. These profiles can be manufactured with anti-slip surfaces or integrated with other safety features to enhance traction and prevent accidents on the walkways. Furthermore, FRP pultrusion profiles possess excellent electrical insulation properties, making them suitable for walkway systems in areas where minimizing electrical conductivity is necessary, such as power plants or electrical substations. All in all, the distinctive properties of FRP pultrusion profiles make them a dependable and versatile material choice for walkway systems. They offer long-lasting performance, low maintenance requirements, and enhanced safety.

Send your message to us

FRP Pultrusion Profiles Molded Gratings

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m

- Supply Capability:

- 50000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords