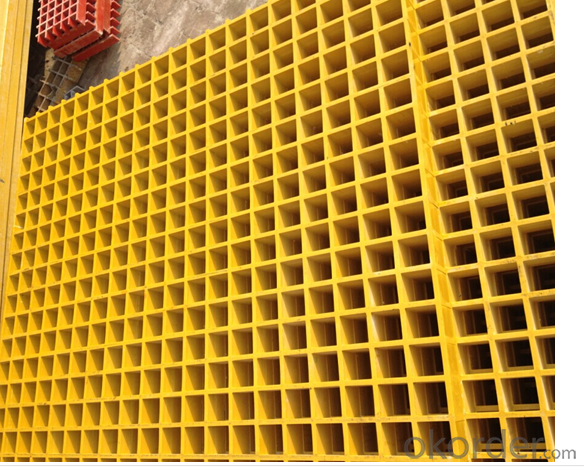

FRP Pultrusion Profiles Molded Gratings - High Quality Fiberglass & Plastic Grating Floors

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction

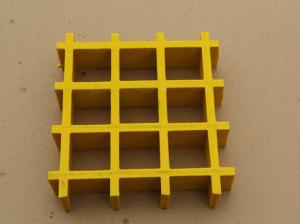

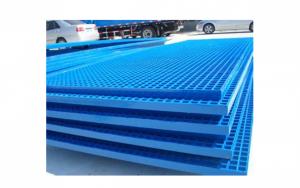

FRP Molded Grating is a structural panel which uses high-strength E-Glass roving as reinforcing material, thermosetting resin as matrix and then casted and formed in a special metal mold. It provides properties of light weight, high strength, corrosion resistance, fire resistance and anti-skid. FRP Molded Grating is widely used in oil industry, power engineering, water & waste water treatment, ocean survey as working floor, stair tread, trench cover, etc. and is an ideal loading frame for corrosion circumstances.

Feature

l Corrosion Resistance

l Fire Resistance

l Light Weight & High Strength

l Safety & Anti-slip

l Electrical Insulating

l Aging Resistance

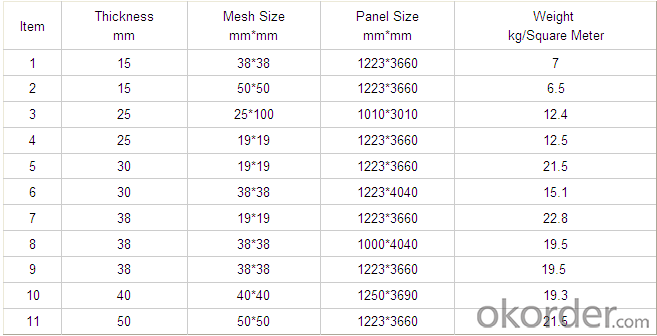

Specification

Advantage

1) coated with prevent aging layer

2) excellent insulating performance

3) no maintenance

4) high strength

5) long service life

6) easy installation

Application

l Power plants, substation equipment enclosures, antimagnetic, anti-static,to prevent small animals into the equipment failure, as there is electricity facilities and without power interval intervals.

l In high voltage electrical equipment for power line work, in order to prevent workers go wrong location, charged interval or near electrically charged equipment to dangerous distance.

l Pool railings in sewage treatment industry

l Corrosive chemical industry equipment around the fence

l All kinds of building maintenance section

FAQ

1. How about the documents after shipment?

After shipment, we ll send all original documents to you by DHL, including Packing List.Commercial Invoice, B/L, and other certificates as required by clients.

2. How long is the delivery time?

Usually it takes 10-25days after receipt of the deposits or L/C, and it also depends on the quantity of your order.

3. How's the payment?

Telegraphic Transfer(T/T) or Letter of Credit(L/C)

4. Do You Arrange Shipment?

Yes, dear esteemed customers, for FOB or CIF price, we will arrange shipment for you. For EXW price, clients need to arrange shipment by themselves or their agents.

5. How is the package?

Usually, we arrange the standard out-package for exporting.

PROCESS

FACTORY

- Q: Can FRP pultrusion profiles be used in water treatment plants?

- Indeed, water treatment plants can utilize FRP (Fiber Reinforced Polymer) pultrusion profiles. The utilization of FRP pultrusion profiles in this industry brings forth numerous advantages that render them highly suitable. To begin with, FRP pultrusion profiles possess exceptional resistance to corrosion. Given the aggressive environments found in water treatment plants, where exposure to chemicals and moisture is common, the traditional materials like steel are prone to corrosion and degradation. However, FRP pultrusion profiles are immune to corrosion, making them an ideal choice for water treatment applications. Moreover, FRP pultrusion profiles exhibit remarkable strength-to-weight ratios. This implies that they offer superior structural integrity while being lightweight, rendering them easier to handle and install within water treatment plants. Additionally, their high strength enables them to endure the loads and pressures typically encountered in these environments. Furthermore, FRP pultrusion profiles are non-conductive of electricity. This feature is particularly advantageous within water treatment plants where there may be a necessity to isolate electrical equipment or components to prevent short circuits and safeguard personnel. FRP profiles provide a safe and dependable solution in such cases. Lastly, FRP pultrusion profiles possess a long service life and necessitate minimal maintenance. They do not rot, rust, or corrode, ensuring durability and longevity even in harsh water treatment conditions. This reduces downtime and maintenance costs, making FRP profiles a cost-effective choice for water treatment plant applications. All in all, due to their corrosion resistance, high strength-to-weight ratio, electrical non-conductivity, and long service life, FRP pultrusion profiles are an exceptional option for utilization in water treatment plants. Their usage can contribute to enhanced efficiency, reduced maintenance, and increased durability in water treatment processes.

- Q: Are FRP pultrusion profiles resistant to biological growth, such as mold or mildew?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles are highly resistant to biological growth, including mold and mildew. FRP materials are inherently non-porous, making it difficult for microorganisms to attach and grow on their surface. Additionally, FRP pultrusion profiles are typically manufactured using a combination of resin and glass fibers, which are both naturally resistant to biological growth. Unlike traditional materials such as wood or metal, FRP does not provide an ideal environment for mold or mildew to thrive. The smooth and non-porous surface of FRP profiles prevents moisture absorption, which is essential for the growth of microorganisms. Furthermore, FRP materials do not contain organic compounds that can support the growth of mold or mildew, making them highly resistant to biological degradation. In applications where resistance to biological growth is crucial, FRP pultrusion profiles offer a significant advantage over alternative materials. They are commonly used in environments with high humidity, moisture, or exposure to water, such as marine, agricultural, or wastewater treatment facilities. Additionally, FRP profiles are frequently employed in indoor applications where mold or mildew growth can be a concern, such as in sanitary areas or food processing plants. Overall, FRP pultrusion profiles provide excellent resistance to biological growth, including mold and mildew. Their non-porous nature, combined with the inherent resistance of the materials used in their manufacturing, make them a durable and long-lasting solution in environments where microbial growth is a potential issue.

- Q: What is the shear strength of FRP pultrusion profiles?

- The shear strength of FRP (Fiber Reinforced Plastic) pultrusion profiles can vary depending on several factors such as the type and quality of fibers used, the resin matrix, and the manufacturing process. Generally, FRP pultrusion profiles have high shear strength due to the continuous fibers running along the length of the profile. The shear strength of FRP pultrusion profiles is typically determined through testing according to industry standards such as ASTM D2344 or ISO 14129. These tests involve subjecting the profile to a shear force until failure occurs, allowing for the calculation of the shear strength. The exact shear strength values for FRP pultrusion profiles can vary significantly depending on the specific composition and design of the profile. However, it is not uncommon for FRP pultrusion profiles to exhibit shear strengths in the range of 50-150 MPa (megapascals) or higher. This makes them suitable for a wide range of structural applications where shear forces are prevalent. It is important to note that the shear strength of FRP pultrusion profiles can be influenced by factors such as temperature, moisture, and exposure to chemicals. Therefore, it is essential to consider the specific environmental conditions and requirements of the application when determining the appropriate FRP profile to be used. Overall, FRP pultrusion profiles are known for their excellent shear strength, which contributes to their popularity and effectiveness in various industries such as construction, transportation, and infrastructure.

- Q: Can FRP pultrusion profiles be used in the construction of wastewater treatment tanks?

- Indeed, wastewater treatment tanks can effectively utilize FRP pultrusion profiles. These profiles are renowned for their exceptional strength-to-weight ratio, resistance to corrosion, and longevity, making them an optimal option for harsh environments such as wastewater treatment facilities. To manufacture FRP pultrusion profiles, continuous fibers like glass or carbon are drawn through a resin bath and subsequently through a heated die to attain the desired shape. This process yields profiles with consistent cross-sections and outstanding mechanical properties. In the construction of wastewater treatment tanks, FRP pultrusion profiles can serve various purposes. They can function as structural components, like beams, columns, and bracing systems, offering the necessary strength and rigidity to support the tank structure. Additionally, FRP profiles can reinforce concrete structures, bolstering their durability and resistance against chemical attack from the wastewater. Moreover, FRP pultrusion profiles can be engineered to endure the corrosive impact of the chemicals and gases found in wastewater treatment tanks. Unlike conventional materials such as steel or concrete, FRP exhibits a high resistance to corrosion, guaranteeing an extended service life and reduced maintenance expenses. Furthermore, FRP profiles provide advantages in terms of installation and transportation. They are lightweight, enabling easier handling and diminished labor requirements during construction. The modular nature of FRP profiles also facilitates swift assembly and disassembly, simplifying maintenance and modifications. Overall, incorporating FRP pultrusion profiles in the construction of wastewater treatment tanks offers numerous benefits, including superior strength, corrosion resistance, durability, and ease of installation. These advantages render FRP a dependable and cost-effective choice for wastewater treatment facilities.

- Q: Are FRP pultrusion profiles resistant to termites or other pests?

- FRP pultrusion profiles possess inherent resistance against termites and other pests. Unlike traditional wood or metal materials, FRP profiles fail to serve as a food source for termites or any other pests. FRP comprises reinforced fibers and a polymer matrix, typically constructed from fiberglass and resin. These constituents lack appeal to pests and do not provide any nutritional value, thus rendering FRP profiles highly resistant to termite damage or infestation. The capability of withstanding pests is among the numerous benefits of employing FRP pultrusion profiles across diverse applications, particularly in outdoor or humid settings, where termites frequently thrive.

- Q: What is the cost of FRP pultrusion profiles compared to other materials?

- The cost of FRP pultrusion profiles is generally lower compared to other materials such as steel or aluminum. This is due to the relatively low cost of raw materials used in the manufacturing process, as well as the efficiency and speed of the pultrusion production method. Additionally, the long lifespan and low maintenance requirements of FRP pultrusion profiles make them a cost-effective choice in the long run.

- Q: Can FRP pultrusion profiles be used in water treatment plants?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in water treatment plants. FRP pultrusion profiles offer several advantages that make them well-suited for use in this industry. Firstly, FRP pultrusion profiles are highly corrosion resistant. Water treatment plants often have aggressive environments with exposure to chemicals and moisture, which can cause corrosion and degradation of traditional materials like steel. However, FRP pultrusion profiles are immune to corrosion, making them an ideal choice for water treatment applications. Secondly, FRP pultrusion profiles have excellent strength-to-weight ratios. This means that they provide high structural integrity while being lightweight, making them easier to handle and install in water treatment plants. Additionally, their high strength allows them to withstand the loads and pressures typically encountered in these environments. Furthermore, FRP pultrusion profiles are electrically non-conductive. This is particularly advantageous in water treatment plants, where there may be a need to isolate electrical equipment or components to prevent short circuits and protect personnel. FRP profiles provide a safe and reliable solution in such cases. Lastly, FRP pultrusion profiles have a long service life with minimal maintenance requirements. They do not rot, rust, or corrode, ensuring durability and longevity even in harsh water treatment conditions. This reduces downtime and maintenance costs, making FRP profiles a cost-effective choice for water treatment plant applications. Overall, FRP pultrusion profiles are an excellent choice for use in water treatment plants due to their corrosion resistance, high strength-to-weight ratio, electrical non-conductivity, and long service life. Their use can contribute to improved efficiency, reduced maintenance, and increased durability in water treatment processes.

- Q: Are FRP pultrusion profiles resistant to fungi and mold?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles are generally resistant to fungi and mold. This is due to the non-porous nature of the materials used in their construction, such as fiberglass and epoxy resins. These materials do not provide a suitable environment for fungi and mold to grow, making FRP pultrusion profiles highly resistant to their growth and colonization. Furthermore, FRP pultrusion profiles are inherently moisture-resistant, which is another factor that discourages the growth of fungi and mold. Unlike traditional materials like wood, which can absorb moisture and provide a conducive environment for fungal and mold growth, FRP profiles do not absorb water and are therefore highly resistant to these issues. The combination of non-porous materials and moisture resistance makes FRP pultrusion profiles a suitable choice for applications where fungi and mold resistance is crucial, such as in humid or damp environments. However, it is important to note that no material is entirely immune to fungi and mold growth under all circumstances. In certain extreme conditions, where there is prolonged exposure to high levels of moisture and organic matter, it is still possible for some fungi and mold to colonize FRP profiles. However, compared to other materials, FRP pultrusion profiles offer a significantly higher level of resistance to these issues.

- Q: Can FRP pultrusion profiles be used in walkway systems?

- Yes, FRP pultrusion profiles can be used in walkway systems. FRP pultrusion profiles are lightweight, strong, and resistant to corrosion, making them suitable for use in various applications, including walkways. They offer durability, low maintenance, and can withstand heavy loads, making them a reliable choice for walkway systems.

- Q: Can FRP pultrusion profiles be used for structural applications?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can definitely be used for structural applications. Pultrusion is a manufacturing process that creates continuous, reinforced profiles by pulling fiber reinforcements through a resin bath and then through a heated die to cure the resin. This process results in strong, lightweight, and corrosion-resistant profiles that have excellent mechanical properties. FRP pultrusion profiles are widely used in various structural applications due to their high strength-to-weight ratio. These profiles can be engineered to have specific load-bearing capacities, stiffness, and durability, making them suitable for a range of structural requirements. Some common structural applications for FRP pultrusion profiles include bridges, walkways, platforms, handrails, supports, beams, columns, and reinforcements in concrete structures. They are also used in applications where traditional materials like steel or wood are not suitable due to corrosion, electrical conductivity, or weight concerns. FRP pultrusion profiles offer several advantages over traditional materials. They are lightweight, which makes them easier to handle and transport. Additionally, they are resistant to corrosion, chemicals, and UV radiation, providing long-term durability even in harsh environments. Moreover, they have excellent dimensional stability, meaning they do not warp, twist, or shrink over time. In conclusion, FRP pultrusion profiles are highly suitable for structural applications due to their strength, lightweight nature, corrosion resistance, and durability. They offer a cost-effective alternative to traditional materials while providing superior performance in various structural projects.

Send your message to us

FRP Pultrusion Profiles Molded Gratings - High Quality Fiberglass & Plastic Grating Floors

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords