FRP Pultrusion Profiles - Fiberglass FRP Panel Molded Plastic Floor Grating

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m

- Supply Capability:

- 80000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

PRODUCT DESCRIPTION

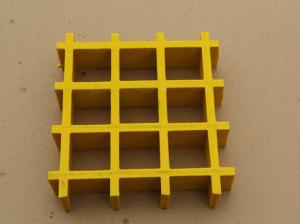

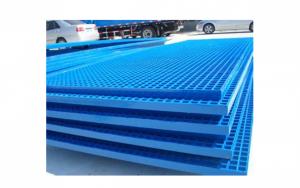

FRP grating is one kind of new composite material, made of different resins reinforced with fiberglass, by molded technology.It is widely used in operation platform, checking and repairing walkway, drilling platform, terrace, stair step, equipment walkway, trench cover, pedestrian overpass, filler support, deck of ship,falsework, ventilation fence, rail, corrosion resistance shelf,etc.

Pultruded grating is made by a particular assembly process, which using “I” shape as its main load-bearing and special rod to go through the bearing bar. Pultruded grating include the standard grating and the custom grating, the custom grating can be designed to meet customer’s requirement or special using condition by changing the shape, size and space of the bearing bars, the surface can be covered with lozenge panel, grit panel, or added the anti-slippery sand directly.

FRP pultruded grating has the most characteristics of molded grating, but it has its distinct advantages, it has very high fiberglass content in the loading direction, so it has very high load capability, it has more superiority when used at wide span, so that the basic support will be decreased and the project cost will be reduced accordingly.

FEATURES

a. anti-corrosion, non-rusty

b. lightweight and high strength

c. anti-flammable

d. anti-fatigue

e. anti-slippery and safety

f. anti-ageing

g. easy to installation and maintenance

h. excellent electromagnetism propert

SPECIFICATION

| Product Details | |

| Brand | CMAX |

| Model NO. | BQ-1071 |

| Color | Any Pantone color or multi-colors can be customized. |

| Size | Length: can be cut any length you want. |

| plz see above photo | |

| thickness: 3mm | |

| surface | glossy |

| MOQ: | 100pcs |

| Payment Term: | TT(Telegraphic Transfer),L/C(letter of credit), Paypal, western union, HSBC Hong Kong. |

| Production Capacity: | 70000pcs Per week |

| Shipping port | Shenzhen |

| Additional term | 1. Any customized shape and size are available. 2. If necessary, we will provide some professional suggestion for your reference. |

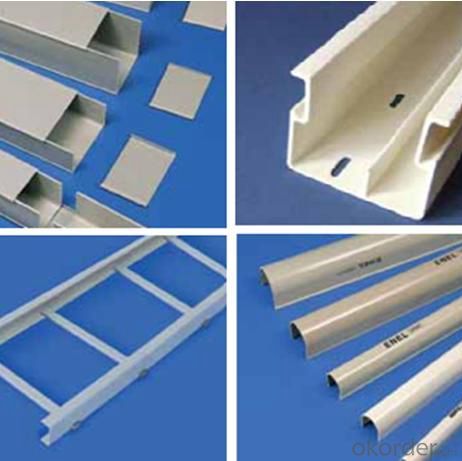

PICTURES

- Q: How do FRP pultrusion profiles perform in electrical grounding systems?

- FRP pultrusion profiles perform well in electrical grounding systems due to their non-conductive properties. Unlike metal profiles, FRP profiles do not carry electrical current, making them a safe and effective choice for electrical grounding applications. Additionally, FRP profiles are corrosion-resistant, durable, and lightweight, making them a reliable and long-lasting option for grounding systems.

- Q: Can FRP pultrusion profiles be used in agricultural applications?

- Yes, FRP pultrusion profiles can be used in agricultural applications. These profiles offer several advantages such as high strength, corrosion resistance, and durability, making them suitable for various agricultural structures and equipment. They can be used for applications like greenhouse structures, livestock housing, irrigation systems, and fencing, among others. Additionally, FRP profiles are lightweight and easy to install, making them a cost-effective choice for agricultural applications.

- Q: How do FRP pultrusion profiles compare to traditional materials, such as steel or aluminum?

- Compared to traditional materials like steel or aluminum, FRP pultrusion profiles present several benefits. Firstly, they are significantly lighter in weight, which facilitates handling and transportation. This advantage is particularly valuable in industries where weight reduction is crucial, such as aerospace or automotive. Furthermore, FRP pultrusion profiles possess high corrosion resistance, unlike steel, which is prone to rust, and aluminum, which can corrode in specific environments. This resistance to corrosion makes FRP profiles ideal for use in harsh or corrosive surroundings, such as chemical plants or coastal areas. Another advantage of FRP pultrusion profiles is their exceptional strength-to-weight ratio. Despite being lightweight, they exhibit remarkable strength and stiffness, often surpassing steel and aluminum. This strength allows for the creation of structurally efficient components, reducing material and installation costs. Additionally, FRP profiles are non-conductive, providing inherent insulation properties. This characteristic makes them suitable for applications where electrical conductivity is undesirable, such as electrical cabinets or offshore platforms. In terms of thermal conductivity, FRP pultrusion profiles have low thermal conductivity compared to metals. This feature improves insulation and minimizes heat transfer, making them suitable for applications that require temperature control or insulation, such as refrigeration or thermal insulation systems. Lastly, FRP pultrusion profiles offer high customizability. They can be easily molded into intricate shapes and sizes, allowing for design flexibility and meeting specific project requirements. This versatility makes FRP profiles suitable for a wide range of applications, including construction, infrastructure, and industrial sectors. Overall, FRP pultrusion profiles provide numerous advantages over traditional materials like steel or aluminum, including lighter weight, corrosion resistance, high strength-to-weight ratio, electrical insulation, low thermal conductivity, and design flexibility. These benefits make FRP profiles the preferred choice in various industries, providing cost-effective and reliable solutions.

- Q: Are FRP pultrusion profiles resistant to termites or other pests?

- FRP pultrusion profiles possess inherent resistance against termites and other pests. Unlike traditional wood or metal materials, FRP profiles fail to serve as a food source for termites or any other pests. FRP comprises reinforced fibers and a polymer matrix, typically constructed from fiberglass and resin. These constituents lack appeal to pests and do not provide any nutritional value, thus rendering FRP profiles highly resistant to termite damage or infestation. The capability of withstanding pests is among the numerous benefits of employing FRP pultrusion profiles across diverse applications, particularly in outdoor or humid settings, where termites frequently thrive.

- Q: Can FRP pultrusion profiles be used in electrical or telecommunications applications?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in electrical or telecommunications applications. FRP pultrusion profiles are known for their excellent electrical insulating properties, high strength-to-weight ratio, and corrosion resistance. These characteristics make them suitable for various electrical and telecommunications applications. In electrical applications, FRP pultrusion profiles can be used as electrical insulators, cable trays, busbar supports, and electrical enclosures. They provide insulation and protection against electrical shocks and are often chosen as an alternative to traditional materials like metal or wood due to their non-conductive properties. Additionally, FRP pultrusion profiles are lightweight and easy to install, which further adds to their suitability in electrical applications. In telecommunications applications, FRP pultrusion profiles are used for cable management systems, antenna supports, and equipment enclosures. Similar to electrical applications, the non-conductive nature of FRP pultrusion profiles ensures the safety and reliability of the telecommunications infrastructure. The profiles can also be customized to meet specific design requirements, such as incorporating cable routing channels or mounting brackets for equipment. Furthermore, FRP pultrusion profiles offer excellent resistance to harsh environmental conditions, such as moisture, UV radiation, and chemicals. This makes them ideal for outdoor electrical or telecommunications installations, where exposure to these elements is common. Overall, FRP pultrusion profiles have proven to be a reliable and cost-effective choice for electrical and telecommunications applications, providing insulation, strength, durability, and resistance to environmental factors.

- Q: Are FRP pultrusion profiles resistant to caustic soda?

- Yes, FRP pultrusion profiles are generally resistant to caustic soda. The corrosion-resistant properties of FRP make it suitable for use in environments that involve caustic soda or other aggressive chemicals. However, it is always recommended to evaluate the specific conditions and concentration of the caustic soda to ensure the compatibility of FRP profiles.

- Q: Can FRP pultrusion profiles be used in wastewater or sewage treatment plants?

- Yes, FRP pultrusion profiles can be used in wastewater or sewage treatment plants. FRP (Fiber Reinforced Plastic) materials offer excellent corrosion resistance, high strength-to-weight ratio, and durability, making them suitable for harsh environments like wastewater treatment facilities. These profiles can be used for various applications such as gratings, handrails, ladders, walkways, and structural supports, providing a long-lasting and low-maintenance solution for these facilities.

- Q: Are FRP pultrusion profiles resistant to chemicals used in food processing?

- Yes, FRP (Fiber Reinforced Plastic) pultrusion profiles are highly resistant to chemicals used in food processing. They are specifically engineered to withstand harsh chemical environments, including the cleaning and sterilization agents commonly used in food processing facilities. This resistance makes FRP pultrusion profiles a suitable material choice for various applications in the food industry where chemical resistance is crucial.

- Q: Are FRP pultrusion profiles resistant to fading or discoloration?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles are highly resistant to fading and discoloration. This is due to the inherent properties of the materials used in their construction. FRP profiles are typically made with a combination of fiberglass reinforcements and a polymer resin matrix, which are both inherently resistant to UV radiation and other environmental factors that cause fading and discoloration. The polymer resin matrix used in FRP profiles is specifically formulated to provide excellent chemical resistance and UV stability, ensuring that the profiles maintain their original color and appearance over an extended period of time. This makes FRP pultrusion profiles an ideal choice for outdoor applications, where exposure to sunlight and other harsh weather conditions is common. Furthermore, the manufacturing process of pultrusion ensures that the color of FRP profiles is consistent throughout their entire cross-section. This means that even if there is minor surface damage or wear, the underlying color of the profile remains the same, ensuring a consistent appearance. Overall, FRP pultrusion profiles offer superior resistance to fading and discoloration, making them a durable and long-lasting option for various applications, such as construction, infrastructure, transportation, and more.

- Q: Can FRP pultrusion profiles be used in the construction of modular storage systems?

- Yes, FRP pultrusion profiles can be used in the construction of modular storage systems. FRP (Fiber Reinforced Polymer) pultrusion profiles offer several advantages that make them suitable for such applications. Firstly, FRP pultrusion profiles are lightweight yet extremely strong and durable. This makes them ideal for modular storage systems where weight is a concern, as they can provide structural support without adding excessive load. Additionally, their high strength-to-weight ratio ensures that the storage systems can withstand heavy loads and provide long-lasting performance. Secondly, FRP pultrusion profiles are corrosion-resistant. This is a crucial characteristic for storage systems, especially those used in outdoor or harsh environments where exposure to moisture, chemicals, or extreme temperatures can lead to corrosion. By using FRP pultrusion profiles, the storage systems can be protected against corrosion, ensuring their longevity and reducing maintenance requirements. Furthermore, FRP pultrusion profiles can be easily customized to meet the specific requirements of modular storage systems. They can be designed in various shapes, sizes, and configurations, allowing for flexibility in the design and construction process. This makes it easier to create storage systems that fit specific spaces and accommodate different types of items. Lastly, FRP pultrusion profiles offer excellent electrical insulation properties. This can be particularly beneficial in storage systems where electrical components or sensitive materials need to be stored. The insulation provided by FRP pultrusion profiles helps protect against electrical hazards and ensures the safety of the stored items. In conclusion, FRP pultrusion profiles are a suitable material choice for the construction of modular storage systems. Their lightweight yet strong nature, corrosion resistance, customization possibilities, and electrical insulation properties make them a reliable and efficient solution for this application.

Send your message to us

FRP Pultrusion Profiles - Fiberglass FRP Panel Molded Plastic Floor Grating

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m

- Supply Capability:

- 80000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords