FRP Pultrusion Profiles Molded Gratings for Stairs & Racks

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 m.t.

- Supply Capability:

- 30000 m2 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

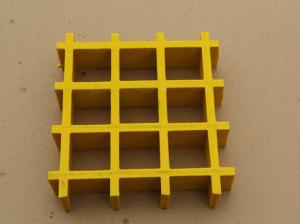

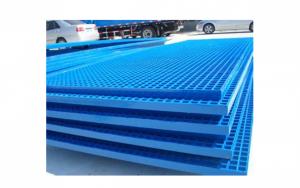

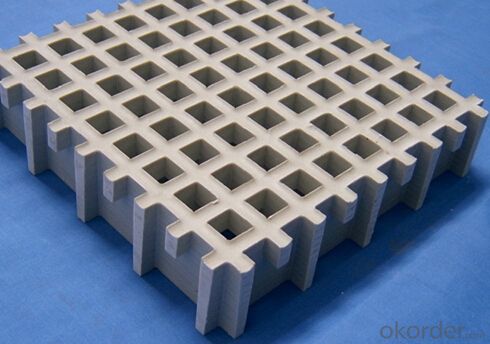

Product description of FRP Grating

FRP Grating, Molded FRP Grating, Fiberglass Grating, GRP Grating,GRP Molded Grating,FRP Pultrusion Grating, FRP Mini Mesh Grating,Trench Grating, Drain Grating,Grating Walkway, Platform Grating...

Comparing with other floor materials, FRP molded grating provides a series of benefits, unmatched impact resistance,

while the strength-weight-ratio is only one-fourth of that of steel grating. It is easy to cut and install.

Specification of FRP Grating

Item | Thickness mm | Mesh Size mm*mm | Panel Size mm*mm | Weight kg/Square Meter |

01 | 15 | 38*38 | 1223*3660 | 7 |

02 | 15 | 50*50 | 1223*3660 | 6.5 |

03 | 25 | 25*100 | 1010*3010 | 12.4 |

04 | 25 | 19*19 | 1223*3660 | 12.5 |

05 | 30 | 19*19 | 1223*3660 | 21.5 |

06 | 30 | 38*38 | 1223*4040 | 15.1 |

07 | 38 | 19*19 | 1223*3660 | 22.8 |

08 | 38 | 38*38 | 1000*4040 | 19.5 |

09 | 38 | 38*38 | 1223*3660 | 19.5 |

10 | 40 | 40*40 | 1250*3690 | 19.3 |

11 | 50 | 50*50 | 1223*3660 | 21.5 |

Images

Features

1.Corrosion and Chemical resistant

2.Slip-resistant

3.High strength-to-weight ratio

4.Ergonomic

5.Low maintenance

6.Fire retardant

7.Easily fabricated and installed

FAQ:

1. Why Choose us?

CNBM is a stated own company, provide the guarantee for the best quality, best service and safety business.

2. How will we guarantee the quality?

a, ISO 9001-2008 quality control system;

b, Strict and regular quality control in production;

c, Inspeciation when loading into container before shippment;

d, Sample stock for one year for quality tracing and records

- Q: What are the different shapes and sizes of FRP pultrusion profiles available?

- FRP (Fiber Reinforced Polymer) pultrusion profiles are available in a wide range of shapes and sizes to cater to various applications and industries. Some of the commonly available shapes include: 1. Square and rectangular profiles: These profiles are available in different sizes and are widely used in construction, infrastructure, and industrial applications. They offer excellent structural strength and can be used as beams, columns, or other load-bearing elements. 2. Round profiles: Round FRP pultrusion profiles are often used as structural supports, handrails, and guardrails. They are available in various diameters to suit different requirements. 3. I-beams: FRP I-beams are popular in the construction industry due to their high strength-to-weight ratio. They are often used as structural members, supporting elements, or floor joists. 4. Channel profiles: Channel-shaped FRP profiles are used for applications that require a combination of strength and versatility. They find applications in cable trays, equipment supports, and framing systems. 5. Angle profiles: FRP angle profiles are commonly used as reinforcements or supports in construction and industrial settings. They provide stability and structural integrity to various components. 6. Custom profiles: Apart from the standard shapes mentioned above, FRP pultrusion profiles can also be customized to meet specific requirements. Manufacturers can create profiles with unique shapes and sizes to suit the needs of different applications. It is important to note that the availability of shapes and sizes may vary among manufacturers. Therefore, it is advisable to consult with suppliers or manufacturers to determine the specific range of FRP pultrusion profiles they offer.

- Q: Can FRP pultrusion profiles be used in the water and wastewater treatment industry?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in the water and wastewater treatment industry. FRP pultrusion profiles are highly durable, corrosion-resistant, and have excellent mechanical properties, making them suitable for various applications in the water and wastewater treatment industry. One of the main advantages of FRP pultrusion profiles is their resistance to corrosion. Water and wastewater treatment facilities often deal with aggressive chemicals, high humidity, and corrosive environments. Traditional materials like steel or wood may deteriorate and require frequent maintenance or replacement. However, FRP pultrusion profiles are specifically designed to withstand harsh conditions without corrosion, ensuring long-term performance and reducing maintenance costs. Additionally, FRP pultrusion profiles offer excellent strength-to-weight ratio, making them ideal for structural applications in water and wastewater treatment facilities. They can be used as walkways, handrails, grating, ladders, and other structural components. The lightweight nature of FRP profiles allows for easy installation and minimizes the load on the supporting structures. Furthermore, FRP pultrusion profiles are non-conductive, providing an added safety benefit in water and wastewater treatment facilities. This property is particularly important when dealing with electrical equipment or applications near water sources, reducing the risk of electrical hazards. Moreover, FRP pultrusion profiles can be customized to meet specific design requirements, including different shapes, sizes, and colors. This flexibility allows for greater design freedom, ensuring that the profiles can be tailored to fit the specific needs of water and wastewater treatment projects. Overall, the use of FRP pultrusion profiles in the water and wastewater treatment industry offers numerous advantages, including corrosion resistance, high strength, lightweight, non-conductivity, and design flexibility. These qualities make FRP profiles a reliable and cost-effective choice for various applications in this industry.

- Q: Can FRP pultrusion profiles be used in the construction of swimming pool enclosures?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in the construction of swimming pool enclosures. FRP pultrusion profiles are known for their excellent strength-to-weight ratio, corrosion resistance, and durability, making them an ideal choice for outdoor applications like swimming pool enclosures. FRP pultrusion profiles are made by pulling fiberglass rovings through a resin bath and then through a heated die, resulting in a continuous profile of uniform shape and strength. This manufacturing process ensures that the profiles are strong, stiff, and lightweight, making them easy to handle and install. In the construction of swimming pool enclosures, FRP pultrusion profiles can be used for various structural elements such as beams, columns, trusses, and panels. These profiles can provide the necessary strength and support while also offering resistance to corrosion, moisture, and UV radiation, which are common challenges in a swimming pool environment. Additionally, FRP pultrusion profiles can be customized to meet specific design requirements, allowing for flexibility in creating unique and aesthetically pleasing swimming pool enclosures. They can be fabricated in a variety of shapes, sizes, and colors, making it possible to achieve the desired architectural look and feel. Overall, FRP pultrusion profiles offer a reliable and long-lasting solution for constructing swimming pool enclosures, providing the necessary strength, durability, and resistance to environmental factors. Their lightweight nature also makes them easier to handle and install, reducing construction time and costs.

- Q: Can FRP pultrusion profiles be used in the construction of theme park rides?

- Yes, FRP pultrusion profiles can be used in the construction of theme park rides. FRP (Fiber Reinforced Polymer) pultrusion profiles are known for their high strength-to-weight ratio, corrosion resistance, and durability, making them suitable for various structural applications. These profiles can be used to build ride components such as supports, beams, frames, and safety structures, providing a lightweight yet robust solution for theme park rides.

- Q: What are the main uses of pultruded glass fiber reinforced plastic extrusions?

- Spend entertainment mall, this is a potential market, the development of use: fishing rod, curtain rod, umbrella frame, flagpole, stuff handle, lamp, railings, handrails and staircases, radio antenna, marinas, garden tools and accessories.

- Q: Can FRP pultrusion profiles be used in the transportation and logistics industry?

- Yes, FRP pultrusion profiles can be used in the transportation and logistics industry. These profiles offer a lightweight and high-strength alternative to traditional materials like steel or aluminum. They are resistant to corrosion, have excellent dimensional stability, and can be customized to meet specific design requirements. FRP pultrusion profiles are commonly used in applications such as truck bodies, trailers, shipping containers, and infrastructure for transportation and logistics purposes.

- Q: Can FRP pultrusion profiles be used in the telecommunications industry?

- Indeed, the telecommunications industry can use FRP (Fiber Reinforced Polymer) pultrusion profiles. These profiles have numerous advantages that make them appropriate for telecommunications applications. Firstly, FRP pultrusion profiles are both lightweight and immensely strong, making them perfect for telecommunications infrastructure. They can be utilized in the design and construction of structures such as antenna mounts, support poles, cable trays, and enclosures. The lightweight nature of FRP profiles simplifies installation and maintenance, reducing the overall cost and effort involved in establishing and upkeeping telecommunications systems. Secondly, FRP pultrusion profiles possess exceptional corrosion resistance properties. This is especially crucial in the telecommunications industry, as infrastructure components are frequently exposed to harsh weather conditions and environmental factors. Unlike traditional materials like steel or aluminum, FRP profiles do not rust or corrode, guaranteeing their durability and dependability in telecommunications applications. Moreover, FRP pultrusion profiles provide electrical insulation properties, which are essential in the telecommunications industry. These profiles do not conduct electricity, making them suitable for applications requiring electrical grounding or isolation. This characteristic ensures the safety of telecommunications equipment and personnel. Furthermore, FRP pultrusion profiles can be tailored to meet specific project requirements. They can be engineered with specific dimensions, shapes, and load-bearing capacities as needed. This flexibility allows for the design and fabrication of telecommunications infrastructure that meets the unique demands of each project. In conclusion, FRP pultrusion profiles are well-suited for telecommunications applications due to their lightweight, high strength, corrosion resistance, electrical insulation properties, and customization options. These profiles offer a reliable and cost-effective solution for various applications within the telecommunications sector.

- Q: Can FRP pultrusion profiles be used in the construction industry?

- Indeed, the construction industry can utilize FRP (Fiber Reinforced Polymer) pultrusion profiles. These profiles offer numerous benefits that make them appropriate for diverse construction applications. To begin with, FRP pultrusion profiles possess exceptional strength while remaining lightweight. Consequently, they are an excellent choice for construction projects as they provide a high strength-to-weight ratio. This reduces the overall weight of the structure while preserving its structural integrity. This advantage is particularly valuable for applications like bridges, walkways, and platforms. Furthermore, FRP pultrusion profiles exhibit a high level of resistance to corrosion. Unlike conventional construction materials such as steel or wood, FRP does not rust, rot, or corrode when exposed to harsh environmental conditions, chemicals, or moisture. Consequently, FRP profiles are ideal for outdoor or marine applications where corrosion can be a concern, such as seawalls, docks, or offshore structures. In addition, FRP pultrusion profiles possess excellent electrical and thermal insulation properties. This makes them suitable for applications where minimizing electrical conductivity is necessary, such as electrical enclosures or cable trays. Moreover, FRP profiles have low thermal conductivity, which enhances energy efficiency in buildings by reducing heat transfer. Furthermore, FRP pultrusion profiles are highly durable and require minimal maintenance. They boast a long service life and do not necessitate regular painting, sealing, or treatment like traditional materials. Consequently, significant cost savings can be achieved throughout the life cycle of a construction project. Lastly, FRP pultrusion profiles can be customized to meet specific strength, stiffness, and dimensional requirements. They can be produced in various shapes, sizes, and colors, allowing for flexibility in design. This versatility renders FRP profiles suitable for a wide range of construction applications, including beams, columns, gratings, handrails, and structural components. To summarize, FRP pultrusion profiles are a viable choice for the construction industry due to their lightweight nature, high strength, corrosion resistance, electrical and thermal insulation properties, durability, low maintenance requirements, and design flexibility.

- Q: Are FRP pultrusion profiles resistant to hydraulic oils?

- Yes, FRP pultrusion profiles are generally resistant to hydraulic oils. The combination of fiberglass reinforcement and resin matrix used in pultrusion manufacturing makes these profiles highly resistant to various chemicals, including hydraulic oils. However, it is recommended to consult the specific resin manufacturer or supplier for detailed information on the compatibility of their FRP pultrusion profiles with different types of hydraulic oils.

- Q: Plastic or better glass fiber reinforced plastic better?

- Plastic steel and glass fiber reinforced plastic have their own advantages, in the mechanical manufacturing and vehicles, ships and other industrial fields, glass fiber reinforced plastic is used; in furniture decoration, the use of plastic steel profiles.

Send your message to us

FRP Pultrusion Profiles Molded Gratings for Stairs & Racks

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 m.t.

- Supply Capability:

- 30000 m2 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords