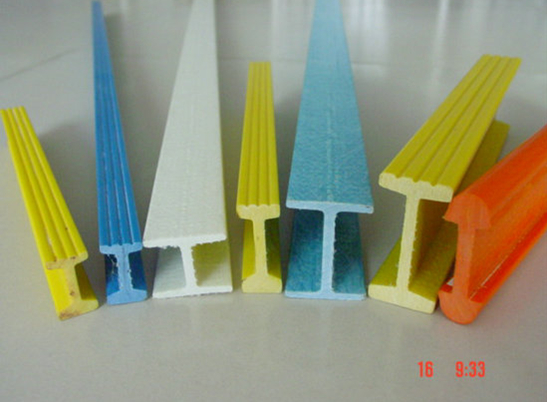

FRP Pultrusion Profiles - C Shape, I Shape

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 m.t.

- Supply Capability:

- 20000m m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product description of FRP Pultrusion Profile

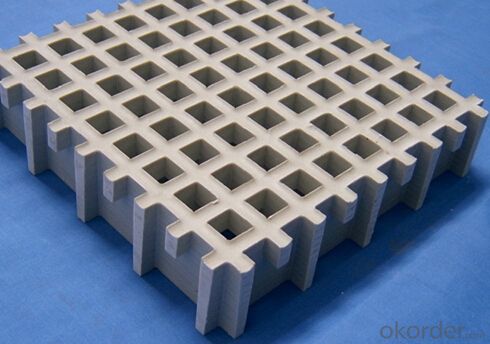

FRP Grating, Molded FRP Grating, Fiberglass Grating, GRP Grating,GRP Molded Grating,FRP Pultrusion Grating, FRP Mini Mesh Grating,Trench Grating, Drain Grating,Grating Walkway, Platform Grating...

Comparing with other floor materials, FRP molded grating provides a series of benefits, unmatched impact resistance,

while the strength-weight-ratio is only one-fourth of that of steel grating. It is easy to cut and install.

Specification of FRP Pultrusion Profile

Item | Thickness mm | Mesh Size mm*mm | Panel Size mm*mm | Weight kg/Square Meter |

01 | 15 | 38*38 | 1223*3660 | 7 |

02 | 15 | 50*50 | 1223*3660 | 6.5 |

03 | 25 | 25*100 | 1010*3010 | 12.4 |

04 | 25 | 19*19 | 1223*3660 | 12.5 |

05 | 30 | 19*19 | 1223*3660 | 21.5 |

06 | 30 | 38*38 | 1223*4040 | 15.1 |

07 | 38 | 19*19 | 1223*3660 | 22.8 |

08 | 38 | 38*38 | 1000*4040 | 19.5 |

09 | 38 | 38*38 | 1223*3660 | 19.5 |

10 | 40 | 40*40 | 1250*3690 | 19.3 |

11 | 50 | 50*50 | 1223*3660 | 21.5 |

Images

Features Of FRP Pultrusion Profile

1.Corrosion and Chemical resistant

2.Slip-resistant

3.High strength-to-weight ratio

4.Ergonomic

5.Low maintenance

6.Fire retardant

7.Easily fabricated and installed

FAQ:

1. Why Choose us?

CNBM is a stated own company, provide the guarantee for the best quality, best service and safety business.

2. How will we guarantee the quality?

a, ISO 9001-2008 quality control system;

b, Strict and regular quality control in production;

c, Inspeciation when loading into container before shippment;

d, Sample stock for one year for quality tracing and record.

- Q: Can FRP pultrusion profiles be used in the renewable energy and solar power industry?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in the renewable energy and solar power industry. These profiles offer several advantages such as high strength, durability, corrosion resistance, and lightweight properties, making them suitable for various applications in the industry. FRP pultrusion profiles can be used for structural components, support structures, mounting systems, and other applications in solar panels, wind turbines, wave energy devices, and other renewable energy systems.

- Q: Can FRP pultrusion profiles be used in the construction of water slides?

- Yes, FRP pultrusion profiles can be used in the construction of water slides. FRP stands for Fiber Reinforced Polymer, which is a composite material that offers several advantages for water slide construction. Firstly, FRP pultrusion profiles are lightweight yet incredibly strong, making them ideal for creating the structural components of water slides. These profiles have high strength-to-weight ratios, meaning they can withstand the dynamic loads and forces experienced in water slide applications without adding excessive weight to the structure. Secondly, FRP pultrusion profiles are highly resistant to corrosion, which is essential for water slide construction. Water slides are constantly exposed to water, chemicals, and harsh weather conditions, which can cause traditional materials like steel to corrode and degrade over time. FRP profiles, on the other hand, are inherently corrosion-resistant, ensuring the longevity and durability of the water slide. Additionally, FRP pultrusion profiles offer design flexibility. They can be customized to various shapes and sizes, allowing for the creation of unique and exciting water slide designs. These profiles can also be easily molded, allowing for the incorporation of various features such as slides, curves, and drops to enhance the overall water slide experience. Lastly, FRP pultrusion profiles have excellent thermal insulation properties. This is beneficial for water slides as it helps maintain the temperature of the water, preventing excessive heat loss or gain. This feature enhances the comfort and enjoyment of users while reducing energy consumption for heating or cooling the water. In conclusion, FRP pultrusion profiles are well-suited for water slide construction due to their lightweight, high strength, corrosion resistance, design flexibility, and thermal insulation properties.

- Q: Can FRP pultrusion profiles be used in agricultural applications?

- Indeed, FRP pultrusion profiles are applicable in the field of agriculture. Renowned for their remarkable strength-to-weight ratio, resistance to corrosion, and durability, FRP pultrusion profiles are an ideal choice for a variety of agricultural uses. One common utilization of FRP pultrusion profiles in agriculture is the construction of livestock enclosures, encompassing fences, gates, and pens. These profiles possess outstanding resistance to weather conditions, chemicals, and degradation caused by UV rays, ensuring their long-lasting performance in outdoor environments. Furthermore, their lightweight composition facilitates ease of handling and installation. Moreover, FRP pultrusion profiles find application in the production of agricultural equipment and machinery. They can be employed for structural components, such as beams and supports, as well as functional parts like handles, brackets, and covers. The impressive strength of FRP profiles enables them to withstand heavy loads and challenging operating conditions, while their resistance to corrosion guarantees their longevity in corrosive surroundings such as fertilizer storage areas or livestock waste management systems. Additionally, FRP pultrusion profiles can be utilized for irrigation systems in agriculture. Their non-conductive nature renders them perfect for situations requiring electrical insulation, such as the creation of irrigation pipes or channels. Furthermore, the corrosion resistance of FRP profiles ensures their ability to endure exposure to water, chemicals, and fertilizers frequently employed in agricultural irrigation. To summarize, FRP pultrusion profiles exhibit exceptional suitability for agricultural applications due to their high strength, resistance to corrosion, and durability. Whether employed in livestock enclosures, agricultural machinery, or irrigation systems, FRP profiles offer numerous advantages that position them as a reliable choice within the agricultural industry.

- Q: How do FRP pultrusion profiles perform in extreme temperatures?

- FRP pultrusion profiles are renowned for their exceptional performance in extreme temperatures. Their distinctive composition of fiberglass and resin matrix grants them a remarkable resistance to thermal expansion and contraction. As a result, even in the most frigid or scorching environments, FRP profiles retain their structural integrity without any warping or deformation. When exposed to high temperatures, FRP pultrusion profiles display an impressive stability in terms of dimensions, as they do not undergo softening or melting like certain other materials. With a high glass transition temperature, they can endure extreme heat without compromising their strength or shape. This quality renders FRP profiles fitting for applications such as furnace components, exhaust systems, and industrial ovens. Conversely, in exceedingly cold temperatures, FRP pultrusion profiles maintain their toughness and durability. They do not turn brittle or susceptible to cracking, unlike conventional materials like metal or concrete. This characteristic makes them suitable for employment in cold storage facilities, refrigerated trucks, and various low-temperature environments. Additionally, FRP pultrusion profiles exhibit excellent resistance to chemical corrosion. They remain unaffected when exposed to a multitude of chemicals or solvents, making them well-suited for harsh chemical processing environments. This resistance to chemical corrosion also extends to extreme temperatures, further enhancing their performance in such conditions. All things considered, FRP pultrusion profiles have established themselves as reliable and versatile materials for extreme temperature environments. Their capacity to uphold structural integrity, dimensional stability, and resistance to chemical corrosion positions them as the preferred choice for diverse industries and applications where temperature extremes are a concern.

- Q: Can FRP pultrusion profiles be used in the oil and gas industry?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in the oil and gas industry. These profiles offer excellent corrosion resistance, high strength-to-weight ratio, and low maintenance requirements, making them suitable for various applications in the industry such as pipe supports, cable trays, handrails, and platforms. Additionally, FRP pultrusion profiles are non-conductive, non-magnetic, and possess good fire-retardant properties, making them a safer alternative to traditional materials in hazardous environments.

- Q: Are FRP pultrusion profiles resistant to ultraviolet radiation?

- Yes, FRP pultrusion profiles are generally resistant to ultraviolet radiation. The combination of the composite material and the resin used in pultrusion manufacturing provides excellent UV resistance, making them suitable for outdoor applications.

- Q: Are FRP pultrusion profiles suitable for the manufacturing of antenna masts?

- Yes, FRP pultrusion profiles are suitable for the manufacturing of antenna masts. FRP pultrusion profiles offer several advantages such as high strength-to-weight ratio, corrosion resistance, and excellent electrical insulation properties. These characteristics make them ideal for antenna mast construction, as they can withstand various environmental conditions and provide reliable support for antennas.

- Q: Are FRP pultrusion profiles non-conductive?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles are non-conductive. This is because they are made up of a combination of reinforced fibers, typically fiberglass, and a polymer resin matrix. The fiberglass fibers provide the strength and stiffness, while the polymer resin acts as a binder to hold the fibers together. One of the key advantages of FRP pultrusion profiles is their excellent electrical insulation properties. Unlike metals, which are conductive, FRP profiles do not conduct electricity. This makes them ideal for applications where electrical insulation is required. In addition to being non-conductive, FRP pultrusion profiles also offer other benefits such as corrosion resistance, high strength-to-weight ratio, and low maintenance requirements. These properties make them suitable for a wide range of applications, including electrical and telecom infrastructure, chemical processing plants, bridges, and building construction. It is important to note that the non-conductive nature of FRP pultrusion profiles does not mean they cannot be made conductive if required. Special additives or coatings can be incorporated during the manufacturing process to impart conductive properties if needed.

- Q: Can FRP pultrusion profiles be used in the construction of water slides?

- Yes, FRP pultrusion profiles can be used in the construction of water slides. FRP, or fiberglass reinforced plastic, offers excellent strength, durability, and corrosion resistance, making it a suitable material for water slide components. The pultrusion process allows for the production of customized profiles with specific shapes and dimensions, ensuring compatibility with water slide design requirements. Additionally, FRP's lightweight nature simplifies installation and maintenance while providing a safe and enjoyable experience for water slide users.

- Q: Are FRP pultrusion profiles suitable for the manufacturing of chemical reactors?

- Yes, FRP pultrusion profiles are suitable for the manufacturing of chemical reactors. FRP (Fiber Reinforced Polymer) pultrusion profiles offer excellent resistance to corrosion, high strength-to-weight ratio, and dimensional stability, making them ideal for use in chemical reactors. Additionally, FRP materials can withstand a wide range of chemical environments and temperatures, making them a reliable choice for this application.

Send your message to us

FRP Pultrusion Profiles - C Shape, I Shape

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 m.t.

- Supply Capability:

- 20000m m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords