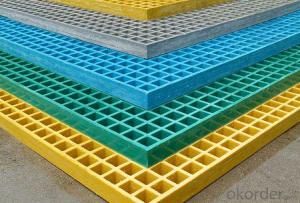

Fiberglass FRP Panel Molded Plastic Floor Flooring

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 70000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

PRODUCT DESCRIPTION

FRP flooring panel is a big size profile which is made by pultrusion technology and in holistic shape, it could form a continuours close plane by unique self-lock structure,which could be used as load structures in various corrosion environments and could replace wood plate, aluminum plate or steel plate etc.

The product could add natural color grit on the surface,which is safe for the anti-slippery,besides it could obtain

the natural appearance and no fadding for a long time.

FEATURES

1) Corrosion and chemical resistant

2) High strength-to-weight ratio

3) Fire retardant

4) Ergonomic

5) Slip-resistant

6) Anti-aging

7) Easy maintenance

SPECIFICATIONS

Item | Size(mm) | Weight(kg/m) |

01 | 25×25x3.2x3.2 | 0.52 |

02 | 32x32x3.2x3.2 | 0.68 |

03 | 38x38x4x4 | 0.98 |

04 | 50x50x4x4 | 1.36 |

05 | 50x50x5x5 | 1.67 |

06 | 50x50x6.3x6.3 | 2.06 |

07 | 60x60x7x7 | 3.2 |

08 | 100x100x6x6 | 4.56 |

09 | 38x38x7x7 | 2.02 |

PICTURES

FAQ

Q1:How Can I Get A Sample?

A1:You can get samples by communicate with our export sales.

Q2:How Long Is Delivery?

A2:Delivery time will be 30days according to order quantity.

Q3:What Is The MOQ?

A3:MOQ depends on different items.

Q4:What Is Our Normal Payments Terms?

A4:Our normal payment terms now is: T/T, L/C or western union,paypal

- Q: Can FRP pultrusion profiles be used in wastewater or sewage treatment plants?

- FRP pultrusion profiles are applicable for use in wastewater or sewage treatment plants. These materials possess exceptional resistance against corrosion, making them an ideal option for environments that frequently encounter chemicals, moisture, and harsh conditions, such as wastewater treatment plants. Compared to conventional materials like steel or concrete, FRP pultrusion profiles offer numerous advantages. They are lightweight, yet incredibly sturdy and long-lasting, facilitating easy installation while maintaining resistance against damage or degradation over time. Additionally, FRP profiles possess non-conductive properties and display good thermal insulation, which can prove advantageous in specific applications within wastewater treatment plants. Moreover, FRP materials exhibit immunity to corrosion and rust, even when exposed to aggressive chemicals and gases commonly present in wastewater or sewage treatment plants. This corrosion resistance significantly prolongs the lifespan of FRP pultrusion profiles, thereby reducing the necessity for frequent maintenance and replacement. To summarize, owing to their corrosion resistance, durability, and other favorable properties, FRP pultrusion profiles are an appropriate choice for a variety of applications in wastewater or sewage treatment plants, including walkways, platforms, handrails, grating, and structural supports.

- Q: Can FRP pultrusion profiles be used in the construction of pedestrian bridges?

- Pedestrian bridges can utilize FRP pultrusion profiles, which offer numerous advantages for bridge construction. Firstly, these profiles are lightweight yet incredibly strong and durable, making them ideal for weight-sensitive pedestrian bridges. The lightweight nature of FRP profiles also simplifies transportation and installation, resulting in cost savings. Secondly, FRP pultrusion profiles are corrosion-resistant, a critical factor in bridge construction. Unlike traditional materials such as steel or concrete, FRP does not rust or corrode, even in harsh environments. This property significantly prolongs the lifespan of pedestrian bridges while reducing maintenance costs. Moreover, FRP pultrusion profiles provide design flexibility. They can easily be tailored to meet specific project requirements, allowing for the creation of unique and innovative bridge designs. The material can be molded into various shapes and sizes, enabling the construction of aesthetically pleasing pedestrian bridges. Furthermore, FRP pultrusion profiles possess excellent mechanical properties, including a high strength-to-weight ratio and fatigue resistance. This ensures that the bridge can withstand the loads and stresses imposed by pedestrian traffic over an extended period. Lastly, FRP pultrusion profiles are non-conductive, making them a safe choice for pedestrian bridges. In areas where there are overhead power lines or electrical equipment, the non-conductive nature of FRP reduces the risk of electrical accidents. In conclusion, FRP pultrusion profiles are a suitable option for constructing pedestrian bridges due to their lightweight, corrosion-resistant, customizable, and mechanically strong properties. Their usage can result in durable, low-maintenance, and visually appealing bridges that provide a safe and efficient means of pedestrian transportation.

- Q: Can FRP pultrusion profiles be used in the construction of pedestrian tunnels?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in the construction of pedestrian tunnels. FRP is a lightweight and high-strength material that offers numerous advantages over traditional construction materials like steel or concrete. One of the main advantages of using FRP pultrusion profiles in the construction of pedestrian tunnels is their corrosion resistance. Unlike steel, FRP does not corrode when exposed to moisture or harsh environmental conditions. This makes FRP profiles ideal for underground structures such as pedestrian tunnels where water seepage or high humidity can be a concern. Additionally, FRP pultrusion profiles have excellent mechanical properties, including high tensile strength and stiffness. This allows them to withstand heavy loads and provide structural integrity to the tunnel. The lightweight nature of FRP also makes it easier to handle and install, reducing the construction time and costs. Furthermore, FRP profiles can be easily molded into various shapes and sizes, making them highly versatile for designing pedestrian tunnels. They can be customized to meet specific project requirements, such as the curvature or dimensions of the tunnel. This flexibility in design allows for creative and efficient solutions in tunnel construction. In terms of safety, FRP pultrusion profiles have a high fire resistance and are non-conductive, which is crucial in ensuring the safety of pedestrians in tunnels. They also have a low thermal conductivity, providing insulation properties that can help maintain a comfortable environment inside the tunnel. Overall, the use of FRP pultrusion profiles in the construction of pedestrian tunnels offers numerous benefits, including corrosion resistance, high strength, versatility in design, and improved safety. These advantages make FRP an excellent choice for constructing durable and efficient pedestrian tunnels.

- Q: How do FRP pultrusion profiles perform in coastal environments?

- FRP pultrusion profiles are highly durable and perform exceptionally well in coastal environments. The combination of fiberglass reinforcement and resin matrix makes them resistant to corrosion, moisture, and UV radiation, which are prevalent in coastal areas. These profiles have excellent resistance to saltwater, chemicals, and other harsh elements commonly found in coastal environments. Due to their corrosion resistance, FRP pultrusion profiles do not rust or degrade over time, unlike traditional materials such as steel or wood. This durability ensures their long-lasting performance and reduces the need for frequent maintenance or replacement. Furthermore, FRP pultrusion profiles have a high strength-to-weight ratio, making them an ideal choice for coastal applications. They are lightweight yet robust, providing structural stability and reliability in harsh coastal conditions. Their non-conductive nature also eliminates the risk of electrical conductivity, which is crucial in coastal areas where saltwater and humidity can cause electrical corrosion. Another advantage of FRP pultrusion profiles in coastal environments is their ability to withstand extreme temperature variations. They can withstand both hot and cold climates without losing their structural integrity or dimensional stability. This makes them suitable for coastal regions with varying weather conditions. In summary, FRP pultrusion profiles excel in coastal environments due to their corrosion resistance, durability, lightweight nature, and ability to withstand extreme weather conditions. Their performance and longevity make them a reliable choice for various applications such as marine structures, coastal infrastructure, and offshore installations.

- Q: Are FRP pultrusion profiles resistant to chemicals used in agricultural applications?

- FRP pultrusion profiles are known for their exceptional resistance to chemicals commonly found in agricultural settings. These profiles are composed of reinforced fibers and a polymer resin matrix, typically polyester or vinyl ester, which provide outstanding protection against a wide range of agricultural chemicals, including fertilizers, pesticides, herbicides, and acids. The inherent corrosion resistance of FRP pultrusion profiles makes them highly sought-after in agricultural applications where exposure to chemicals is prevalent. Unlike traditional materials like wood, steel, or concrete, these profiles do not deteriorate or degrade when exposed to aggressive chemicals. This resistance ensures that the profiles remain structurally sound and perform effectively throughout their long lifespan, even in harsh agricultural conditions. Additionally, FRP pultrusion profiles excel in their resistance to corrosion, moisture, UV radiation, and temperature fluctuations. This durability makes them ideal for a variety of agricultural applications, such as structural supports, fencing, grating, decking, and irrigation systems. However, it is important to note that while FRP pultrusion profiles are highly resistant to chemicals, they may still experience some level of degradation or staining when exposed to extremely concentrated or highly aggressive chemicals. To ensure compatibility with the chosen FRP pultrusion profiles, it is recommended to consult with the manufacturer or supplier regarding the specific chemicals used in the agricultural application.

- Q: What is the cost of FRP pultrusion profiles compared to other materials?

- The cost of FRP pultrusion profiles is generally lower compared to other materials such as steel or aluminum. This is due to the relatively low cost of raw materials used in the manufacturing process, as well as the efficiency and speed of the pultrusion production method. Additionally, the long lifespan and low maintenance requirements of FRP pultrusion profiles make them a cost-effective choice in the long run.

- Q: Are FRP pultrusion profiles resistant to fire?

- FRP pultrusion profiles are known for their fire resistance. They are composed of a resin matrix and reinforcing fibers, such as fiberglass or carbon fiber, which contribute to their excellent fire resistance properties. The resin matrix used in FRP has a high flame resistance rating, while the reinforcing fibers are not easily combustible. Consequently, FRP pultrusion profiles have a high ignition temperature and are naturally self-extinguishing, meaning they stop burning once the flame source is removed. Moreover, FRP pultrusion profiles do not emit toxic fumes or smoke when exposed to fire, making them a safer choice compared to traditional materials like wood or steel. Nevertheless, it is important to acknowledge that the fire resistance of FRP pultrusion profiles may vary depending on the specific resin formulation and reinforcement material utilized.

- Q: Can FRP pultrusion profiles be used in oil and gas applications?

- FRP pultrusion profiles are applicable for oil and gas purposes. These profiles possess exceptional resistance against corrosion, a high strength-to-weight ratio, and durability, making them suitable for a range of industries, including oil and gas. In oil and gas applications, FRP pultrusion profiles can serve multiple functions. They find use in constructing pipelines, offshore platforms, and subsea structures. They can also be utilized for fabricating tanks, vessels, and other equipment that are exposed to corrosive environments. A key advantage of FRP pultrusion profiles in oil and gas applications is their resistance to corrosion. Unlike traditional materials like steel, FRP does not rust or corrode when exposed to moisture, chemicals, or saltwater. This resistance extends the lifespan of the profiles and reduces maintenance costs. Furthermore, FRP pultrusion profiles offer high strength and stiffness. They can withstand high pressures, extreme temperatures, and harsh operating conditions commonly encountered in oil and gas environments. Their lightweight nature also facilitates easier handling and installation, especially when compared to heavier materials such as steel. Another benefit of FRP profiles is their non-conductive property. This characteristic makes them suitable for applications where electrical conductivity should be minimized, such as offshore platforms or areas with potential electrical hazards. In conclusion, FRP pultrusion profiles are a reliable and cost-effective solution for oil and gas applications. Their corrosion resistance, high strength, and lightweight properties make them ideal for various components and structures within the industry.

- Q: Are FRP pultrusion profiles resistant to chemicals used in food processing?

- Yes, FRP (Fiber Reinforced Plastic) pultrusion profiles are highly resistant to chemicals used in food processing. They are specifically engineered to withstand harsh chemical environments, including the cleaning and sterilization agents commonly used in food processing facilities. This resistance makes FRP pultrusion profiles a suitable material choice for various applications in the food industry where chemical resistance is crucial.

- Q: Are FRP pultrusion profiles resistant to chemicals used in power plants?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles are generally resistant to the chemicals commonly used in power plants. FRP composites are known for their excellent chemical resistance properties, making them suitable for a wide range of industrial applications including power plants. The specific chemical resistance of FRP pultrusion profiles can vary depending on the resin matrix used and the specific chemicals they are exposed to. However, in most cases, FRP pultrusion profiles are resistant to chemicals such as acids, alkalis, solvents, and corrosive gases commonly found in power plants. It is important to consult with the manufacturer or supplier of FRP pultrusion profiles to ensure that the specific resin matrix and formulation used meets the requirements for chemical resistance in a power plant environment.

Send your message to us

Fiberglass FRP Panel Molded Plastic Floor Flooring

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 70000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords