Pultruded FRP Fiberglass Deck Flooring Panel, Fiberglass Deck Boards

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m

- Supply Capability:

- 100000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

PRODUCT DESCRIPTION

FRP flooring panel is a big size profile which is made by pultrusion technology and in holistic shape, it could form a continuours close plane by unique self-lock structure,which could be used as load structures in various corrosion environments and could replace wood plate, aluminum plate or steel plate etc.

The product could add natural color grit on the surface,which is safe for the anti-slippery,besides it could obtain the natural appearance and no fadding for a long time.

FEATURES

a. anti-corrosion, non-rusty

b. lightweight and high strength

c. anti-flammable

d. anti-fatigue

e. anti-slippery and safety

f. anti-ageing

g. easy to installation and maintenance

h. excellent electromagnetism property

TECHNICAL DATA

Thickness (mm) | Bar width (mm) | Openspace (mm) | Open rate (%) | Approx weight (kg/m 2 ) |

25.4 | 15.2 | 22.8 | 60 | 13.2 |

25.4 | 15.2 | 15.2 | 50 | 15.9 |

25.4 | 15.2 | 10.1 | 40 | 18.5 |

25.4 | 40 | 10.8 | 21 | 14.5 |

38.1 | 15.2 | 22.8 | 60 | 15.8 |

38.1 | 15.2 | 15.2 | 50 | 19.1 |

38.1 | 15.2 | 10.1 | 40 | 22.4 |

50.8 | 25.4 | 25.4 | 50 | 16.6 |

50.8 | 25.4 | 12.7 | 33 | 21.1 |

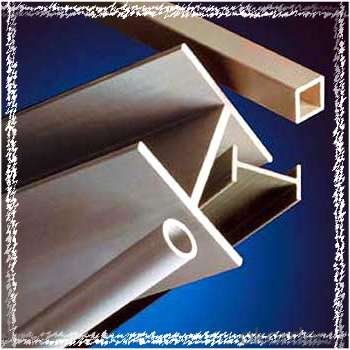

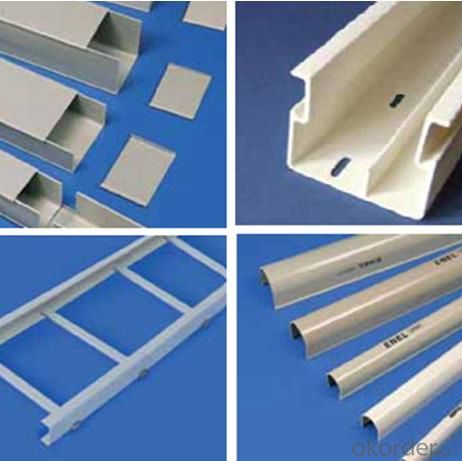

PICTURES

APPLICATION

Deck of cooling tower, plate of scaffold, floor of chip manufacturing, deck of bridge, rooftop, slope of architectural

overhaul, structural floor, floor of light railcar, baffle of equipment, roof of cover, trench cover, footpath, weather

plank.

- Q:How do FRP pultrusion profiles handle cyclic torsion loads?

- FRP pultrusion profiles have been carefully designed to effectively handle cyclic torsion loads. The exceptional properties of FRP materials make them highly resistant to fatigue, which makes them perfectly suitable for applications where cyclic torsion loads are anticipated. A significant advantage of FRP pultrusion profiles lies in their remarkable strength-to-weight ratio. By reinforcing them with fibers like glass or carbon, these profiles exhibit outstanding tensile strength and stiffness, enabling them to withstand repeated torsional forces without any deformation or failure. Furthermore, FRP pultrusion profiles display superior resistance to corrosion and chemical degradation when compared to traditional materials like steel. This resistance guarantees that the profiles maintain their structural integrity even in harsh environments where cyclic torsion loads might be prevalent. The pultrusion manufacturing process also contributes to the capability of FRP profiles to handle cyclic torsion loads. During pultrusion, continuous fibers are impregnated with a polymer resin and then drawn through a heated die, where they are cured and shaped into the desired profile. This process ensures a uniform distribution of fibers throughout the profile, resulting in enhanced strength and stiffness in all directions, including torsion. To further enhance the performance of FRP pultrusion profiles under cyclic torsion loads, engineers utilize design techniques such as optimizing the fiber orientation and selecting suitable resin systems. These measures help evenly distribute the torsional forces across the profile, reducing stress concentrations and enhancing fatigue resistance. In conclusion, FRP pultrusion profiles have been specifically engineered to handle cyclic torsion loads. Their remarkable strength-to-weight ratio, corrosion resistance, and uniform fiber distribution make them an ideal choice for applications where cyclic torsion loads are a concern.

- Q:Are FRP pultrusion profiles resistant to wear or abrasion?

- FRP pultrusion profiles exhibit exceptional durability against wear and abrasion due to the integration of reinforcing fibers, predominantly glass or carbon, and a plastic resin matrix. This combination results in a highly robust material that can endure rigorous utilization. Moreover, the pultrusion process guarantees a uniform composition, with fibers uniformly dispersed throughout the profile, thereby augmenting its resistance to wear and abrasion. Furthermore, FRP pultrusion profiles can be customized with specific additives or surface treatments to further heighten their ability to withstand wear and abrasion, rendering them suitable for diverse applications across industries such as construction, transportation, and marine.

- Q:Are FRP pultrusion profiles resistant to graffiti?

- FRP pultrusion profiles are generally resistant to graffiti due to their unique characteristics and composition. Pultruded fiberglass reinforced plastic (FRP) profiles are manufactured using a combination of high-strength fibers and a polymer resin matrix, resulting in a highly durable and robust material. One of the key advantages of FRP profiles is their excellent resistance to various forms of corrosion, including chemical, moisture, and UV resistance. These properties make FRP profiles less susceptible to the damaging effects of graffiti. Unlike traditional materials such as wood or metal, FRP pultrusion profiles do not provide a porous surface that allows paint or markers to penetrate and adhere easily. Additionally, FRP profiles are often produced with a smooth and non-porous finish, further deterring the attachment of graffiti. Even if graffiti is applied to the surface, it can be easily removed using non-abrasive cleaning methods without causing any damage to the profile's structural integrity or appearance. However, it is important to note that no material is completely immune to graffiti. Determined vandals may still find ways to leave marks on FRP profiles using specialized graffiti materials or techniques. Nonetheless, the resistance of FRP pultrusion profiles to graffiti is significantly higher compared to many other conventional materials, making them an ideal choice for areas prone to vandalism or graffiti attacks.

- Q:What are the different surface finishes available for FRP pultrusion profiles?

- Some of the different surface finishes available for FRP pultrusion profiles include smooth, textured, non-skid, and glossy finishes. These finishes can enhance the aesthetics, improve grip, and provide protection against UV radiation and corrosion.

- Q:Are FRP pultrusion profiles resistant to fungal growth?

- FRP pultrusion profiles are generally resistant to fungal growth. The composite materials, like resins and fibers, used in pultrusion possess inherent resistance to biological degradation, including attacks from fungi. The non-porous nature of FRP pultrusion profiles also poses difficulties for fungi to penetrate and grow on the surface. Furthermore, the manufacturing process involves curing the composite materials at high temperatures, which adds to their resistance against fungal growth. However, it is important to acknowledge that no material is entirely impervious to fungal growth in all conditions. Factors such as high humidity, prolonged exposure to moisture, and inadequate maintenance practices can still contribute to fungal growth on FRP pultrusion profiles, albeit to a lesser extent compared to materials like wood or metal. Regular inspection and appropriate cleaning are crucial to sustain the fungal resistance of FRP pultrusion profiles throughout their lifespan.

- Q:Are FRP pultrusion profiles resistant to high-pressure gas?

- Yes, FRP pultrusion profiles are generally resistant to high-pressure gas due to their excellent corrosion resistance and structural integrity. The inherent properties of FRP, such as high strength-to-weight ratio and non-reactivity to gases, make them suitable for various applications involving high-pressure gas environments. However, it is recommended to consult with the manufacturer or engineer to ensure specific requirements are met for the intended application.

- Q:How do FRP pultrusion profiles perform in corrosive gas environments?

- FRP (Fiber Reinforced Plastic) pultrusion profiles have excellent performance in corrosive gas environments. The unique properties of FRP, such as high corrosion resistance, make them highly suitable for applications where exposure to corrosive gases is a concern. FRP pultrusion profiles are typically made from a combination of glass fibers and a resin matrix, such as polyester or vinyl ester. These materials are inherently resistant to corrosion and do not react with most corrosive gases. As a result, FRP pultrusion profiles can withstand exposure to a wide range of corrosive gases, including sulfur dioxide, hydrogen sulfide, chlorine, and many others. Moreover, FRP pultrusion profiles offer superior durability and long-term performance in corrosive gas environments. They do not rust, corrode, or degrade over time, unlike traditional materials like steel or aluminum. This corrosion resistance ensures that FRP profiles maintain their structural integrity even in harsh environments, reducing maintenance and replacement costs. Additionally, FRP pultrusion profiles can be manufactured with specific chemical-resistant resins and additives to enhance their performance in highly corrosive gas environments. This customization allows for tailoring the FRP profiles to meet the specific requirements of the application, ensuring optimal performance and longevity. Overall, FRP pultrusion profiles are an excellent choice for corrosive gas environments due to their exceptional corrosion resistance, long-term durability, and customization options. They provide a reliable and cost-effective solution for industries such as chemical processing, oil and gas, wastewater treatment, and many others where exposure to corrosive gases is a concern.

- Q:What are the characteristics of FRP products?

- Light high-strengthThe relative density is between 1.5~2.0 and only 1/4~1/5 of carbon steel, but the tensile strength is close to or even higher than that of carbon steel, while the specific strength can be compared with that of advanced alloy steel. As a result, aviation, rockets, aerospace vehicles, high pressure vessels, and other applications that need to reduce weight have excellent results. The tensile, flexural and compressive strengths of some epoxy FRP can reach over 400Mpa.

- Q:What is the compression strength of FRP pultrusion profiles?

- The compression strength of FRP (Fiber Reinforced Polymer) pultrusion profiles varies depending on several factors such as the type of resin, fiber orientation, and design. However, on average, FRP pultrusion profiles have a compression strength ranging from 10,000 to 50,000 pounds per square inch (psi). It is important to note that these values are approximate and may vary depending on the specific application and intended use of the FRP profiles. Additionally, manufacturers typically provide technical data sheets that outline the compression strength and other mechanical properties of their FRP pultrusion products, which can be utilized for more accurate and reliable information.

- Q:Can FRP pultrusion profiles be used in the telecommunications industry?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can indeed be used in the telecommunications industry. FRP pultrusion profiles offer several advantages that make them suitable for telecommunications applications. Firstly, FRP pultrusion profiles are lightweight yet incredibly strong, which makes them ideal for use in telecommunications infrastructure. These profiles can be used for designing and constructing structures such as antenna mounts, support poles, cable trays, and enclosures. The lightweight nature of FRP profiles allows for easier installation and maintenance, reducing the overall cost and effort involved in setting up and maintaining telecommunications systems. Secondly, FRP pultrusion profiles have excellent corrosion resistance properties. This is particularly important in the telecommunications industry, as infrastructure components are often exposed to harsh weather conditions and environmental factors. Unlike traditional materials like steel or aluminum, FRP profiles do not rust or corrode, ensuring their longevity and reliability in telecommunications applications. Additionally, FRP pultrusion profiles offer electrical insulation properties, which is crucial in the telecommunications industry. These profiles do not conduct electricity, making them suitable for applications where electrical grounding or isolation is required. This feature ensures the safety of telecommunications equipment and personnel. Furthermore, FRP pultrusion profiles can be customized to meet specific project requirements. They can be engineered to have specific dimensions, shapes, and load-bearing capacities as needed. This flexibility allows for the design and fabrication of telecommunications infrastructure that meets the specific demands of each project. In summary, FRP pultrusion profiles are well-suited for use in the telecommunications industry due to their lightweight, high strength, corrosion resistance, electrical insulation properties, and customization options. These profiles offer a reliable and cost-effective solution for various applications within the telecommunications sector.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Pultruded FRP Fiberglass Deck Flooring Panel, Fiberglass Deck Boards

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m

- Supply Capability:

- 100000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords