FRP Pultruded Flooring Panel made in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 0 m²

- Supply Capability:

- 0 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description of FRP Pultruded Flooring Panel

FRP flooring panel is a big size profile which is made by pultrusion technology and in holistic shape, it could form a continuours close plane by unique self-lock structure, which could be uesed as load sructures in various corrosion environments and could replace wood plate, aluminum plate or steel plate etc.

The product could add natural color grit on the surface, which is safe for the anti-slippery, besides it could obtain the natural appearance and no fadding for a long time.

Main Features of FRP Pultruded Flooring Panel

Anti-corrosion non-rusty

Light weight and high strength

Anti-flammable

Anti-fatigue

Safe and anti-slippery

Anti-ageing

Easy to installation and maintenance

Excellent electromagnetism property

Specifications of FRP Pultruded Flooring Panel

Product code :60040, Product width: 600mm, Product height: 40mm

Face plate thickness:5mm, Ventral plate thickness:4mm Product weight: 12kg/m

Applications of FRP Pultruded Flooring Panel

Deck of cooling tower, plate of scaffold, floor of chip manufacturing, deck of bridge, rooftop, slope of architectural overhaul, structural floor, floor of light railcar, baffle of equipment, roof of cover, trench cover, footpath, weather plank.

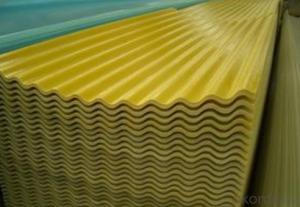

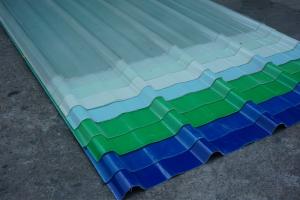

IMages of FRP Pultruded Flooring Panel

FAQ

1. How about the documents after shipment?

After shipment, we ll send all original documents to you by DHL, including Packing List.Commercial Invoice, B/L, and other certificates as required by clients.

2. How long is the delivery time?

Usually it takes 10-25days after receipt of the deposits or L/C, and it also depends on the quantity of your order.

3. How's the payment?

Telegraphic Transfer(T/T) or Letter of Credit(L/C)

4. Do You Arrange Shipment?

Yes, dear esteemed customers, for FOB or CIF price, we will arrange shipment for you. For EXW price, clients need to arrange shipment by themselves or their agents.

5. How is the package?

Usually, we arrange the standard out-package for exporting.

- Q:Can FRP pultrusion profiles be used in the construction of industrial flooring?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in the construction of industrial flooring. FRP pultrusion profiles are made from a composite material that consists of a combination of strong fibers, typically glass or carbon, and a polymer resin. This combination of materials provides exceptional strength, durability, and corrosion resistance, making FRP profiles highly suitable for industrial flooring applications. One of the main advantages of FRP pultrusion profiles is their high strength-to-weight ratio. This makes them lighter and easier to handle compared to traditional materials such as steel or concrete. Additionally, FRP profiles are non-conductive and non-magnetic, which can be beneficial in certain industrial environments. FRP pultrusion profiles are also highly resistant to various chemicals, moisture, and UV radiation, making them ideal for use in harsh and corrosive environments. They do not rust or corrode like steel and are not affected by moisture or rot like wood, ensuring long-lasting performance and minimal maintenance requirements. Furthermore, FRP profiles can be customized and manufactured in different shapes, sizes, and load-bearing capacities to meet specific industrial flooring requirements. They can be designed to withstand heavy loads, impact, vibration, and other dynamic forces commonly encountered in industrial settings. In summary, FRP pultrusion profiles offer numerous advantages that make them suitable for the construction of industrial flooring. Their high strength, durability, corrosion resistance, and customizable nature make them a reliable and cost-effective choice for industrial flooring applications.

- Q:What are the environmental benefits of using FRP pultrusion profiles?

- FRP pultrusion profiles offer several environmental benefits. Firstly, they are lightweight, which reduces the energy required for transportation and installation compared to traditional materials like steel or concrete. This leads to reduced carbon emissions during the entire lifecycle of the product. Additionally, FRP is highly durable and resistant to corrosion, which means that it has a longer lifespan and requires less maintenance and replacement. This reduces waste generation and conserves resources. Moreover, FRP pultrusion profiles are non-toxic and do not release harmful chemicals or pollutants into the environment. Overall, their use contributes to sustainable practices and helps in minimizing the environmental impact of various industries.

- Q:Are FRP pultrusion profiles resistant to chemicals used in agricultural applications?

- FRP pultrusion profiles are known for their exceptional resistance to chemicals commonly found in agricultural settings. These profiles are composed of reinforced fibers and a polymer resin matrix, typically polyester or vinyl ester, which provide outstanding protection against a wide range of agricultural chemicals, including fertilizers, pesticides, herbicides, and acids. The inherent corrosion resistance of FRP pultrusion profiles makes them highly sought-after in agricultural applications where exposure to chemicals is prevalent. Unlike traditional materials like wood, steel, or concrete, these profiles do not deteriorate or degrade when exposed to aggressive chemicals. This resistance ensures that the profiles remain structurally sound and perform effectively throughout their long lifespan, even in harsh agricultural conditions. Additionally, FRP pultrusion profiles excel in their resistance to corrosion, moisture, UV radiation, and temperature fluctuations. This durability makes them ideal for a variety of agricultural applications, such as structural supports, fencing, grating, decking, and irrigation systems. However, it is important to note that while FRP pultrusion profiles are highly resistant to chemicals, they may still experience some level of degradation or staining when exposed to extremely concentrated or highly aggressive chemicals. To ensure compatibility with the chosen FRP pultrusion profiles, it is recommended to consult with the manufacturer or supplier regarding the specific chemicals used in the agricultural application.

- Q:Are FRP pultrusion profiles resistant to high-pressure water jets?

- Yes, FRP pultrusion profiles are generally resistant to high-pressure water jets due to their inherent corrosion resistance and ability to withstand harsh environmental conditions.

- Q:Can FRP pultrusion profiles be used in the water treatment industry?

- Yes, FRP pultrusion profiles can be used in the water treatment industry. FRP (Fiber Reinforced Plastic) offers excellent corrosion resistance and durability, making it suitable for various applications in water treatment plants. FRP pultrusion profiles can be used in the construction of water tanks, pipes, pumps, and other equipment, providing a lightweight and high-strength alternative to traditional materials like steel. Additionally, FRP profiles are non-conductive and have low thermal conductivity, making them ideal for applications involving chemicals and extreme temperature variations commonly found in water treatment processes.

- Q:Can FRP pultrusion profiles be used in the construction of modular buildings?

- Yes, FRP pultrusion profiles can be used in the construction of modular buildings. FRP (Fiber Reinforced Plastic) pultrusion profiles offer several advantages such as high strength-to-weight ratio, corrosion resistance, and design flexibility. These profiles can be easily fabricated into various shapes and sizes, making them suitable for modular building applications. Additionally, FRP pultrusion profiles are durable, low-maintenance, and exhibit excellent thermal insulation properties, making them a reliable choice for constructing modular buildings.

- Q:Can FRP pultrusion profiles be used in water treatment plants?

- Indeed, water treatment plants can utilize FRP (Fiber Reinforced Polymer) pultrusion profiles. The utilization of FRP pultrusion profiles in this industry brings forth numerous advantages that render them highly suitable. To begin with, FRP pultrusion profiles possess exceptional resistance to corrosion. Given the aggressive environments found in water treatment plants, where exposure to chemicals and moisture is common, the traditional materials like steel are prone to corrosion and degradation. However, FRP pultrusion profiles are immune to corrosion, making them an ideal choice for water treatment applications. Moreover, FRP pultrusion profiles exhibit remarkable strength-to-weight ratios. This implies that they offer superior structural integrity while being lightweight, rendering them easier to handle and install within water treatment plants. Additionally, their high strength enables them to endure the loads and pressures typically encountered in these environments. Furthermore, FRP pultrusion profiles are non-conductive of electricity. This feature is particularly advantageous within water treatment plants where there may be a necessity to isolate electrical equipment or components to prevent short circuits and safeguard personnel. FRP profiles provide a safe and dependable solution in such cases. Lastly, FRP pultrusion profiles possess a long service life and necessitate minimal maintenance. They do not rot, rust, or corrode, ensuring durability and longevity even in harsh water treatment conditions. This reduces downtime and maintenance costs, making FRP profiles a cost-effective choice for water treatment plant applications. All in all, due to their corrosion resistance, high strength-to-weight ratio, electrical non-conductivity, and long service life, FRP pultrusion profiles are an exceptional option for utilization in water treatment plants. Their usage can contribute to enhanced efficiency, reduced maintenance, and increased durability in water treatment processes.

- Q:Can FRP pultrusion profiles be used in the construction of amusement park rides?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in the construction of amusement park rides. FRP pultrusion profiles offer numerous advantages that make them suitable for such applications. Firstly, FRP pultrusion profiles are known for their high strength-to-weight ratio. This means that they are significantly lighter than traditional materials like steel while still maintaining excellent structural integrity. As a result, using FRP profiles in amusement park rides can help reduce the overall weight of the structure without compromising on safety. Secondly, FRP pultrusion profiles have excellent corrosion resistance properties. Unlike steel, FRP does not rust or deteriorate when exposed to moisture or chemicals commonly found in amusement park environments. This makes FRP profiles ideal for rides that are constantly exposed to water, humidity, and other harsh conditions. Additionally, FRP pultrusion profiles offer design flexibility. They can be manufactured in various shapes and sizes, allowing for customized designs to meet specific requirements of amusement park rides. This versatility in design enables engineers and designers to create complex and intricate structures that are both aesthetically pleasing and functional. Moreover, FRP pultrusion profiles have excellent electrical insulation properties. This is particularly important for amusement park rides that may have electrical components and wiring, as FRP profiles can provide a high level of safety by preventing electrical conductivity. Furthermore, FRP profiles are non-magnetic, which can be advantageous in amusement park rides that use magnetic systems or sensors. Non-magnetic materials eliminate the risk of interference or disruption to the ride's functionality. Lastly, FRP pultrusion profiles are durable and require minimal maintenance. They are resistant to UV radiation, which means they will not degrade or fade due to prolonged exposure to sunlight. This reduces the need for frequent painting or coating, resulting in lower maintenance costs over time. Overall, the combination of lightweight, corrosion resistance, design flexibility, electrical insulation, non-magnetic properties, and durability make FRP pultrusion profiles an excellent choice for the construction of amusement park rides.

- Q:Can FRP pultrusion profiles be used in protective barriers?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in protective barriers. FRP pultrusion profiles offer excellent strength, durability, and corrosion resistance, making them suitable for various applications including protective barriers. They can withstand impact, extreme weather conditions, and chemicals while providing a lightweight and cost-effective solution for barriers in industries such as construction, transportation, and safety.

- Q:Are FRP pultrusion profiles resistant to chemicals used in oil refineries?

- FRP pultrusion profiles have a high resistance to chemicals utilized in oil refineries. These profiles consist of a combination of strong fibers (such as fiberglass, carbon fibers, or aramid fibers) embedded in a polymer resin matrix. This unique construction grants them exceptional resistance to various chemicals commonly found in oil refineries. The polymer resin matrix used in FRP profiles can be carefully chosen to withstand harsh chemical environments. For oil refinery applications, vinyl ester or epoxy resins are often employed due to their superior chemical resistance properties. Additionally, FRP pultrusion profiles are inherently corrosion-resistant, unlike traditional materials like steel or concrete that deteriorate when exposed to aggressive chemicals found in oil refineries. This corrosion resistance ensures the long-term durability and reliability of FRP profiles in such environments. Furthermore, FRP profiles offer several other advantages in oil refinery applications, including a high strength-to-weight ratio, electrical insulation, non-magnetic properties, and ease of installation. These characteristics make FRP pultrusion profiles an ideal choice for various structural, piping, and equipment applications within oil refineries. However, it is crucial to consider the specific chemicals and concentrations involved in a particular oil refinery application. While FRP profiles generally exhibit excellent resistance to a wide range of chemicals, there may be highly concentrated or specialized chemicals that could potentially impact their performance. In such cases, it is advisable to seek guidance from FRP manufacturers or experts who can offer tailored solutions to meet the specific chemical resistance requirements of the oil refinery.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

FRP Pultruded Flooring Panel made in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 0 m²

- Supply Capability:

- 0 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords