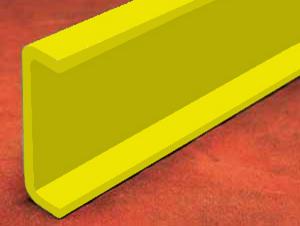

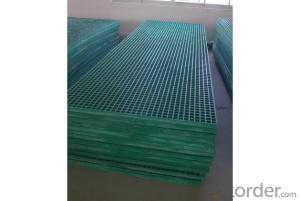

FRP Pultrusion Profile

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100Meters m.t.

- Supply Capability:

- 9999999Meters m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of FRP Pultrusion Profile

FRP fiberglass pultrusion profile

1.ISO 9001

2.High Strength and insulation

3.High Corrosion Resistance

4.Any shape

Description of FRP Pultrusion Profile

1.FRP products are with low weight and high strength.

density:1.5-2, 1/4 of carbon steel, but the same tensile strength with carbon steel. So the FRP products can be widely used in aerospace, rockets,high-pressure container, and so on.

2.Great decay resistance

FRP product has good decay resistance, it has good ability to resist to air, water and general concentration of acid, alkali, salt, and a variety of solvent oil. So, it also can be used in chemical anticorrosion to replace steel, wood and other mentals.

3.Good electrical performance

FRP is a good insulation material, it can keeps good dielectric properties under high frequency.

Good microwave permeability, so it is widely used to make radar antenna mask.

4.good thermal performance

FRP is with low thermal conductivity,in room temperature, it's 1.25~1.67kJ/(m·h·K), is excellent insulation material.

5.Good plasticity

The material can be made into everything according to consumers' request.

Packaging & Delivery of FRP Pultrusion Profile

Packaging Detail: on the pallet

Delivery Detail: within 30 days

- Q: How is FRP pultrusion different from other manufacturing processes?

- FRP pultrusion is different from other manufacturing processes in its unique method of producing fiber-reinforced polymer (FRP) profiles. Unlike traditional processes like extrusion or injection molding, pultrusion involves pulling continuous fibers through a resin bath and then into a heated die, where they are cured and shaped into the desired profile. This continuous and automated process allows for the production of strong, lightweight, and corrosion-resistant FRP profiles with consistent mechanical properties. Additionally, pultrusion enables the incorporation of various fiber orientations and resin systems, making it highly versatile for customized applications.

- Q: Can FRP pultrusion profiles be used in modular construction?

- Yes, FRP pultrusion profiles can be used in modular construction. FRP (Fiber Reinforced Polymer) pultrusion profiles offer several advantages such as high strength-to-weight ratio, corrosion resistance, and design flexibility. These properties make them suitable for various applications in modular construction, including structural elements, cladding, and panel systems. Additionally, FRP pultrusion profiles can be easily molded into different shapes and sizes, making them compatible with the modular construction approach, where standardized components are assembled to create a larger structure.

- Q: Can FRP pultrusion profiles be used in the construction of agricultural structures?

- Yes, FRP pultrusion profiles can be used in the construction of agricultural structures. FRP pultrusion profiles are lightweight, durable, and resistant to corrosion, making them suitable for various agricultural applications such as greenhouse framing, livestock enclosures, and storage sheds. They offer excellent strength-to-weight ratio and can withstand harsh environmental conditions, making them a reliable choice for agricultural construction.

- Q: Are FRP pultrusion profiles resistant to chemical spills or leaks?

- FRP pultrusion profiles are known for their high resistance to chemical spills or leaks, making them an excellent choice for construction projects. One of the main benefits of using FRP as a building material is its exceptional chemical resistance. These profiles are made by impregnating continuous fibers with a thermosetting resin, resulting in a durable composite material. The selection of the resin used in FRP pultrusion profiles depends on the specific chemical environment they will be exposed to. This allows for customization and optimization of the composite's ability to withstand different chemicals. Additionally, the fibers used in FRP are typically chemically inert, further enhancing the profiles' resistance to chemical spills or leaks. FRP pultrusion profiles have proven to be highly resistant to a wide range of chemicals, including acids, alkalis, solvents, and corrosive substances. They are commonly used in industries such as chemical processing, water and wastewater treatment, oil and gas, and marine applications, where exposure to aggressive chemicals is common. Apart from their chemical resistance, FRP pultrusion profiles offer several other advantages. They are lightweight yet strong and stiff, making them ideal for applications that require structural integrity. They are also non-conductive, non-magnetic, and have excellent electrical insulation properties. Overall, FRP pultrusion profiles are a reliable option for environments where chemical spills or leaks are a concern. They provide robust resistance to a wide variety of chemicals, ensuring long-lasting performance and minimal maintenance requirements.

- Q: What are pultrusion materials used for?

- Pultrusion is a kind of glass fiber forming process, the main raw materials are glass fiber and resin

- Q: Can FRP pultrusion profiles be used in high-voltage applications?

- Yes, FRP pultrusion profiles can be used in high-voltage applications. FRP (Fiber Reinforced Polymer) materials are known for their excellent electrical insulation properties, making them suitable for high-voltage environments. Additionally, FRP pultrusion profiles offer advantages such as high strength, corrosion resistance, and lightweight, making them a viable option for high-voltage applications.

- Q: Are FRP pultrusion profiles resistant to impact from flying debris?

- FRP pultrusion profiles possess notable strength and durability, earning them a reputation in the industry. Their inherent properties make them generally impervious to damage caused by flying debris. This exceptional impact resistance can be attributed to the combination of reinforcing fibers, often fiberglass, and the polymer matrix. The extent of resistance to flying debris impact may vary depending on the design, thickness, and composition of the FRP pultrusion profiles. Nevertheless, these profiles are typically engineered to withstand impact forces and effectively withstand damage from airborne debris. Moreover, FRP pultrusion profiles find extensive use in industries such as construction, transportation, and infrastructure, where impact resistance is of utmost importance. These profiles have undergone rigorous testing and have demonstrated their ability to endure various impact scenarios, making them a trustworthy choice for applications that involve the potential for flying debris. It is vital to recognize that although FRP pultrusion profiles boast commendable impact resistance, the severity of the impact and the speed of the flying debris can still impact the degree of damage incurred. Thus, it is advisable to consult with the manufacturer or an engineer to ensure the chosen FRP profile is suitable for the intended application and potential impact conditions.

- Q: Are FRP pultrusion profiles resistant to nitric acid?

- FRP pultrusion profiles are generally resistant to nitric acid. Nitric acid is a strong oxidizing agent and can corrode many materials including metals. However, FRP (Fiber Reinforced Polymer) pultrusion profiles are made of composite materials that are specifically designed to be resistant to various corrosive substances, including nitric acid. The corrosion resistance of FRP pultrusion profiles can be attributed to the combination of their reinforcing fibers, such as fiberglass or carbon fiber, and the resin matrix that binds these fibers together. The resin matrix used in FRP profiles is typically a thermosetting polymer, such as polyester or epoxy, which provides a protective barrier against corrosive substances. Nitric acid is known to attack metals, causing corrosion and degradation. However, FRP pultrusion profiles offer excellent resistance to nitric acid due to the inert nature of the composite materials used. The reinforcing fibers in FRP profiles do not react with nitric acid, and the resin matrix acts as a barrier, preventing the acid from reaching and corroding the fibers. It is important to note that the specific resistance of FRP pultrusion profiles to nitric acid may vary depending on the specific composition of the composite materials used and the concentration and temperature of the nitric acid. Therefore, it is always recommended to consult with the manufacturer or supplier of FRP profiles to ensure their compatibility with nitric acid in specific applications.

- Q: Are FRP pultrusion profiles resistant to moisture?

- Yes, FRP pultrusion profiles are highly resistant to moisture due to the inherent properties of fiberglass and the resin matrix used in their production. This resistance makes them an excellent choice for applications where moisture exposure is a concern, such as outdoor structures, marine environments, and infrastructure exposed to wet conditions.

- Q: Can FRP pultrusion profiles be used in the construction of shipping containers?

- Yes, FRP pultrusion profiles can be used in the construction of shipping containers. FRP (Fiber Reinforced Polymer) pultrusion profiles offer excellent strength-to-weight ratio, corrosion resistance, and durability, making them suitable for various applications including shipping container construction. These profiles can be used for structural components, such as beams, frames, and panels, to enhance the container's strength and longevity. Additionally, FRP pultrusion profiles can be customized to meet specific design requirements and can withstand harsh environmental conditions typically encountered in shipping and transportation.

1. Manufacturer Overview

| Location | Qingdao, China |

| Year Established | 2004 |

| Annual Output Value | Above US$ 80 Million |

| Main Markets | Mid East; South America;Asia |

| Company Certifications | ISO 9001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao |

| Export Percentage | 31% - 40% |

| No.of Employees in Trade Department | 5-10 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 5000 square meters |

| No. of Production Lines | Above 5 |

| Contract Manufacturing | Design Service Offered |

| Product Price Range | Average |

Send your message to us

FRP Pultrusion Profile

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100Meters m.t.

- Supply Capability:

- 9999999Meters m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords