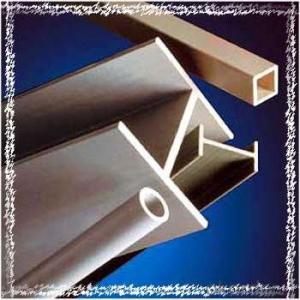

Fiberglass FRP Pultrusion Profile for Door and Window

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m

- Supply Capability:

- 10000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Pultrusion process is a mechanized process for FRP composites involves pulling a collection of fibers in the form of roving mat or fabric through a resin bath and then through a heated die to cure the resin, and then take shapes of profiles. FRP pultruded profiles are more than a kind of structure, which is very designable. Changing the choice of the materials and designs of the lamination process can make special properties for it.

Product Performance:

• Corrosion resistant and anti-ageing

• Water-proof, fire retardant, Heat Resistance

• Very designable, cut discretionarily

• Easy of installation and dimensional stability

• Bright color and good appearance

PROFILE TYPE

By changing different shapes of the mould (die), this production line can produce different profiles or rods.

Application

The FRP channel products can resist corrosion from various gas or liquid such as acid,alkali,organic solvent and compound.They can be used as ladder material,and used in the electricity industries. It can be widely use in railing, bracket of water circulation tower, sport equipment, tool handle, bracket of tent and others loading structure components

FAQ:

1.Who will pay for the express cost ?

A: We can support you free samples ,but express cost will be paid by you .

2.How long is the delivery time?

A:within 10-15 days after receiving deposit.

- Q: There is a suit I saw made of a polyester blend. One button suit with side vents. Isit worth the investment?

- No. Polyester is garbage. Traditional suits are 100% wool. Casual or summer suits can be made from silk, cotton, linen, or other NATURAL fiber. If the cloth was born in a chemical plant, it is garbage.

- Q: How to do dust washing clothes can reach 1000?

- Before washing to scrape, damage and zippers, buttons and other accessories to check for defects to repair, replacement or scrap.

- Q: How do you make scarfs fluffy again after putting it in the washing machine?

- i don't know that is why I am here

- Q: Hi, i got these sweat pants from six flags they are 80% cotton and 20% polyster, and also if i have to do the whole wash in hot water thing, would i still be able to wash my other clothes with it? i really dont wanna waste water. Thank you.

- It's highly unlikely you are going to be able to shrink those sweat pants any significant amount. Most clothing items are made with pre-shrunk cloth, and as there is a 20% polyester component, that would further prevent shrinkage. So just wash them along with your regular clothes in cool or cold water. If you're trying to make the pants smaller, you may have to do a little sewing and take them in. Or take them back and get a smaller size.

- Q: a skirt that is 93% polyester and 7% spandex fabric?

- Have you tried putting the skirt in the freezer just long enough to make the gum easy to remove? That might work!

- Q: Its a formal dress, very silky feeling and shiny. The tag says to spot clean only by a professional cleaner, but it does not say anything about ironing. The bottom is very wrinkly, but that's it. I don't have a steamer and I would rather not go out and buy one. Any suggestions?

- Yes you can still start it but you won't be able to drive it.

- Q: What's the material of the GRC board, please? Have done, please come out to say next?

- GRC is a kind of new building materials, GRC glass fiber products manufacturing there is a glass fiber, the safety coefficient is large, generally used in the European architectural wall decoration, there are many types of friends of GRC lines, GRC relief, GRC window, GRC Rome column etc..

- Q: We currently have a cloth (probably polyester) couch. My husband and I CANNOT stand to sit on it for any length of time, because it is so hot! I don‘t know if its some sort of material that doesn‘t breathe, or what. We are looking into buying a new sofa/sectional, and I have seen a lot of microfiber materials. I know leather can be cooler, but we don‘t want to spend a fortune. So, is microfiber couches/sofas hot to sit on?

- I have microfiber sofa, love seat and chair and I personally do not think they are hot. We spend a lot of time on our sofa and I don't ever remember thinking it was really hot. They are also very easy to clean!

- Q: I love the look and feel of leather but I am a vegetarian and am big on the whole don‘t-eat-or-wear-animals thing so I would never put real leather in my car. So do they actually mean real leather or is it something else? Like a fake leather?

- It is real, natural leather. When it is artificial they call it simili sometimes. Personally I don't like it much in the car, I prefer fabrics.

Send your message to us

Fiberglass FRP Pultrusion Profile for Door and Window

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m

- Supply Capability:

- 10000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords