FRP FRP PULTRUTION PROFILE-Rectangular tube

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Brief Introduction

Pultrusion process is a mechanized process for FRP composites involves pulling a collection of fibers in the form of roving mat or fabric through a resin bath and then through a heated die to cure the resin, and then take shapes of profiles. FRP pultruded profiles are more than a kind of structure, which is very designable. Changing the choice of the materials and designs of the lamination process can make special properties for it. It can be widely use in railing, bracket of water circulation tower, sport equipment, tool handle, bracket of tent and others loading structure components

2.Characteristics

• Corrosion resistant and anti-ageing

• Water-proof, fire retardant, Heat Resistance

• Light weight, high strength and impact strength

• Non-magnetism and non-conductive

• Very designable, cut discretionarily

• Easy of installation and dimensional stability

• Long service life and maintenance-free

• Bright color and good appearance

3.Product Specifications

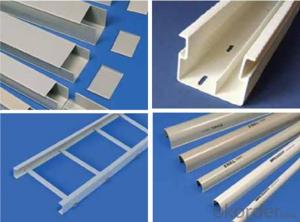

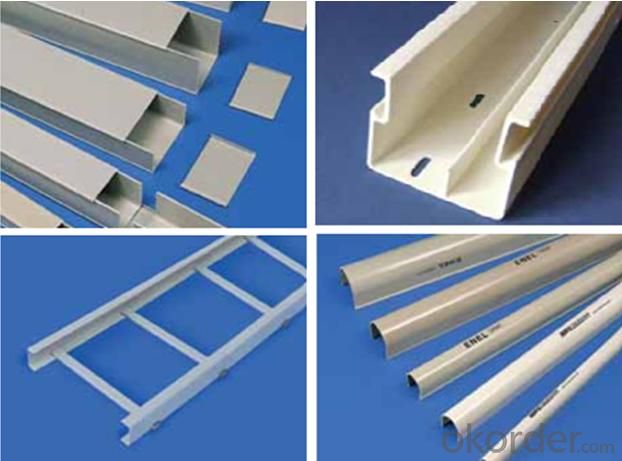

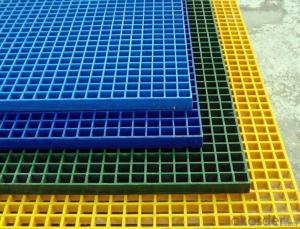

By changing different shapes of the mould (die), this production line can produce different profiles or rods. The following list is some products photos for reference.

No. | Item | No. | Item |

1 | Rectangular tube | 9 | Cable tray |

2 | Square tube | 10 | Handrail |

3 | Round tube | 11 | Profile for door & window |

4 | Channel | 12 | Guardrail |

5 | I-beam | 13 | End fitting of Radome |

6 | Angel | 14 | Shaft of the umbrella& tent |

7 | Epoxy rod | 15 | Profile for bridge |

8 | Platform and ladder | 16 | Ladder |

4.FAQ

Packing and Storage:

Packaging | by carton |

Delivery | 60 days after receiving your deposit |

- Q: If I were to run around in a white fur coat indoors and out I would be filthy in a matter of hours not to mention the weeks between baths my dog gets. I‘ve had a couple of dogs with white fur and day to day activities don‘t ever seem to make it look dirty (there are of course the romps in mud that require an immediate bath -but that isn‘t what I‘m talking about). If anything I would expect their fur to get dirty quicker than our hair. But I couldn‘t go three days without a shampoo with out looking noticeably dirty, the dog can look clean for weeks!

- First of all, I haven't a clue how they really do it--nonetheless, the possibility caught my eye and mind so I thought I take a guess. 1. The first thing that crossed my mind was a fine coating of oil--something like ducks have to water proof their feathers so they don't soak up water. But that didn't make any sense. Any type of liquid or lotion would CAUSE dirt to stick. 2. The second thing to cross my mind was a little closer to my field of interest. Somesort of 'natural' low voltage static. You remember that type of cloth, (I don't remember if it was polyester) that would cause both water and dust to repell from it's surface? This is the direction I'm going with this answer. That cloth had somesort of natural static charge causing this. It is therefore my bottom line OPINION--somekind of natural low voltage static charge is causing this. (Wouldn't it be nice if humans had skin like that!) The way to test this is by petting the pooch lightly--did you feel or hear the static sparks? Sorry I couldn't be of futher help. BYE!

- Q: Mini laptop. Running Windows 7. Hp. Already tried a damp cloth followed by immediate drying.

- I think u are in the wrong section? this is for fish

- Q: Can I Deep/Steam clean my Polyester Fiber couches?

- I certainly have polyester fiber and that i asked Stanley Steamer to bathe it and that they does no longer touch it. They reported it must be wiped clean with a dry Chemical. i think of there's a business enterprise that's stated as Dry Chem.

- Q: How to choose waterproof material for bursting roof?

- Recommended fluoroglycofen good sign roof waterproofing system:Applicable to any complex roof structure, such as joints, parapet, vertical and horizontal lap, out of roof gutters, pipes, steel and various equipment base.

- Q: I just need a little bit to save up for shopping and stuff, I can‘t mow yards and stuff like that for extra income, I am in a wheelchair

- New brakes don't squeak. You might want to find someone else to look at it. Anybody that says brake squeaks, especially on new brakes, is normal is a moron and shouldn't give advice or work on cars

- Q: I noticed that every practitioner has patches of their academy as well as possible sponsors, or companies/affiliations they want to affiliate themselves with. My first competition is in December and I‘d like to show my my school (Go Rams! 8-0). However I don‘t want my patch to be embroidered. The patch itself cannot have borders and needs to be flat. I guess it needs to be printed on a rough canvas material to stitch onto my gi?I‘ve browsed websites but most require bulk orders and aren‘t exactly what I‘m looking for. Is there anyway I can get a personalized patch for myself in the NYC area?

- Make sure that wearing the patch is approved by the school you train in so check with your teacher and the affiliation you are planning to represent. The patches you see on people's gi are not just some random patches you get to pick. Wearing the patches is a 2 way street you showing your affiliation and representing the school where you compete and them wanting to be represented by you. For example if your school does not like UFC it would be improper to go compete in the UFC wearing that patch and representing your school. Try an iron on transfer. You can actually make them on your computer. Get Iron on transfers at a sewing or craft store, print it out MIRROR IMAGE from your computer, iron on a piece of cloth to sew onto your gi or directly onto your gi. I would not use canvas. Simple piece of cotton blend cloth (cotton/polyester) will do nicely.

- Q: Glass fiber has several specifications

- C- glassAlso known as alkali glass, which is characterized by chemical resistance, especially acid resistance is better than that of non alkali glass, but the electrical performance is poor, the mechanical strength is lower than the non alkali glass fiber from 10% to 20%, three a certain amount of boron oxide containing alkali glass fiber usually abroad two, while alkali glass fiber in China is completely free B. In foreign countries, alkali glass fiber is used for the production of glass fiber products such as corrosion, used in the production of glass fiber mat, also for strengthening the asphalt roofing materials, but occupies more than half of the glass fiber production in the medium alkali glass fiber (60%), widely used in FRP and filter fabric, fabric bandage such as the production, because the price is lower than the non alkali glass fiber and has strong competitiveness.

- Q: theres silk, cotton,????? please tell me i would like to kno some brand names to! :)

- There are very few brands of cloth, most can be found at your local fabric store. There are two qualifications in type of cloth 1: Material (I.E. Silk, Cotton, Wool, Rayon, linen, polyester) 2: Weave (I.E. Velvet, Twill, jersey, broad cloth, brocade, gooseye, plain weave, satin) Material specifies what the cloth has been woven from, for example cotton cloth is made from cotton plant fibers, silk is the cocoons of the silk worm, wool comes from sheep, etc. Material can change the quality of the resulting fabric greatly including texture, weight, stretch, softness, and strength. Most natural fibers (ones that come from plants or animals) do not have inherent stretch, so if one wants a stretchy garment made out of one it would have to be knitted. Weave is the pattern in which the fibers of the cloth are woven together, different weave structures have different properties, including pattern or textural differences, stretch, strength, weight, luster and flexibility Materials may be mixed in a single piece of material, so you could have say. a cotton silk blend satin, or a cotton linen blend twill.

- Q: Is there a proper way to wash a guidon or a brassarad?

- okay for the brass i.e. the tip of the guidon or the pike, use a little bit of brasso and a cloth to get the scratches out. folow the instructions on the canister if you get lost. for the cloth of the guidon i would look at the fabric. is it preshrunk cotton? or is it a blend of cotton and polyester? depending on what the fabric is made of you have to adjust. also the color affects washing too. to be pn the safe side i would go with cold water and i would hang dry it because i dont trust machines with important things. and if the flag is really important to you you should just hand wash it if you know how. just be careful not to get bleach on the fabric because nothing is worse than having a guidon that has a flag with a big black or miscolored spot. good luck and i hope it works. i would check with some more people before taking my advice though because ive never washed the flag.

- Q: I am trying to look into cloth diapers but can‘t find a ton of clear how-to information. I have a 15 month old and I am due in November with my second baby. Having two in diapers is going to be outrageously expensive. I‘ve heard that cloth diapers are a lot easier to use today but don‘t know anyone well that has used them.1.)How do wash and care for therm?2.)What are the inserts?3.) What about stains?Etc any info welcomed:-)

- Oh, i grew to become right into a type of mothers that grew to become into purely the organic stuff for my toddler. I wasn't going to apply disposable diapers for something, and that cloth grew to become into the way for me. Yeah, that lasted all of each week. I switched to the objective variety of diapers for my toddler. the professionals: Yeah, that's good sized for the atmosphere, and additionally that's extra useful for the toddler's epidermis, for cloth breaths properly. And that's extra low priced universal to purchase a series of fabric diapers and wash and reuse them. The cons: that's extra convenient to do away with the grimy diaper than rinse and wash it, and it does create a extra useful barrier agains gaps and leaks, inflicting much less injuries simply by a diaper moving in the pants. There additionally are no pins in contact, so no probability of sticking your self or the toddler whilst the toddler comes to a decision that they choose to run, and not be replaced. And that's lots swifter to alter a disposable diaper than a cloth one. The little balls which you're noticing is from the interior the diaper. This usually happens whilst a rip in the lining occures, or you enable the diaper get too finished. particularly circumstances a transformation in manufacturers may be the common restoration, yet now and lower back you may see them. i do no longer think of they are risky in the event that they are in simple terms there, and the youngster does not ingest them. once you spot them, use a washcloth and wash them off. that's what I did once I got here upon them. My daughter is now 17 months previous, and nonetheless going stable in disposable diapers. stable luck!!

Send your message to us

FRP FRP PULTRUTION PROFILE-Rectangular tube

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords