FRP Pultrusion Profile Cable Tray with High Quality

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m

- Supply Capability:

- 100000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

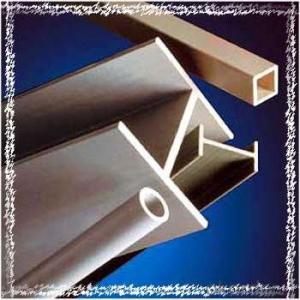

Pultrusion process is a mechanized process for FRP composites involves pulling a collection of fibers in the form of roving mat or fabric through a resin bath and then through a heated die to cure the resin, and then take shapes of profiles. FRP pultruded profiles are more than a kind of structure, which is very designable. Changing the choice of the materials and designs of the lamination process can make special properties for it. It can be widely use in railing, bracket of water circulation tower, sport equipment, tool handle, bracket of tent and others loading structure components

Product features :

• Corrosion resistant and anti-ageing

• Water-proof, fire retardant, Heat Resistance

• Light weight, high strength and impact strength

• Non-magnetism and non-conductive

• Very designable, cut discretionarily

• Easy of installation and dimensional stability

• Long service life and maintenance-free

• Bright color and good appearance

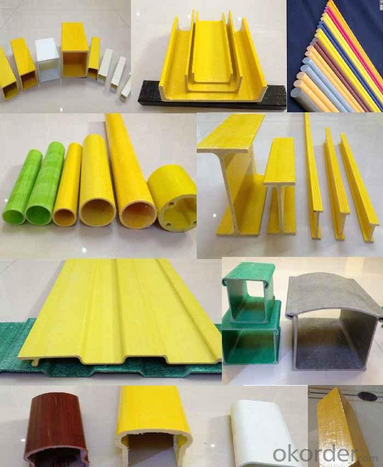

PROFILE TYPE

By changing different shapes of the mould (die), this production line can produce different profiles or rods. The following list is some products photos for reference.

No. | Item | No. | Item |

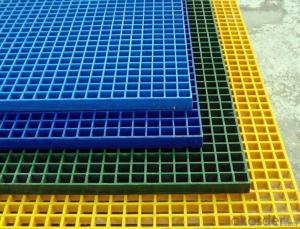

1 | Rectangular tube | 9 | Cable tray |

2 | Square tube | 10 | Handrail |

3 | Round tube | 11 | Profile for door & window |

4 | Channel | 12 | Guardrail |

5 | I-beam | 13 | End fitting of Radome |

6 | Angel | 14 | Shaft of the umbrella& tent |

7 | Epoxy rod | 15 | Profile for bridge |

8 | Platform and ladder | 16 | Ladder |

product Specifications :

Round Rod: D2mm-20mm

Round Tube: OD3mm-38mm

Square Tube: OD12mm-100mm

Channel Rectangular Rod

T-shape and H-shape

C-shape

leg angles

Application

The FRP channel products can resist corrosion from various gas or liquid such as acid,alkali,organic solvent and compound.

They can be used as ladder material,and used in the electricity industries.

FAQ:

1.Who will pay for the express cost ?

A: We can support you free samples ,but express cost will be paid by you .

2.How long is the delivery time?

A:within 10-15 days after receiving deposit.

- Q:how to make a boat of thermocol?

- I'm with Peter.it's core material.cedar is also good. I'm sure you meant it as a core all along, albeit unintentionally. As soon as you coat it with polyester or vinylester or epoxy it becomes sunstrate rather than surface.as a core in particular you would drape some cloth over it as well. So.to the how to.make a male mold or blank ver it in 6mil vapour barrier so you don't accidentally bond to it and mount your thermocol.lay your glass cloth on it and coat. When you have enough built up on the outside and it has cured, pop the hull off the blank and flip it over and glass the inside over simplified, but that's the idea. At any rate.good luck with your project. ps.I'm interested in where that stuff can be bought too if you care to email me. thx. DM

- Q:I tried to remove small stains from a white polyester graduation gown using a cloth. Well the stains came out but now I have water stains. The tag says do not wash or dry clean. Any suggestions?

- Wow, Thank you! I was asking myself the same question the other day

- Q:I have a black trench coat and I want to dye it purple, like the jokers, do you know how I can do that? plz help!!!

- If your coat is made of synthetic fibers (acrylic, polyester), there is no way to change the color. If your coat is made of natural fibers (cotton, linen, rayon, wool), it is possible that you can bleach the black dye partly, then use RIT dye from the drugstore to dye it purple. Bleaching it will weaken the fabric, and ruin any waterproofing that it may currently have. To bleach a natural-fiber cloth, use a large bucket or a stopped-up sink in an area that is well-ventilated. With gloves on, use about one part non-colorsafe bleach to ten parts water. Mix up the liquid before you add the (DRY) cloth. Wait about half an hour, then put the cloth into the washing machine by itself and run it through a cycle with detergent. Dry the cloth, then follow the directions on the RIT box to dye.

- Q:Spilt a couple of drops of red wine on our blue carpet and can‘t get it out.

- Pour a little white wine on the red wine stain right away. If no white wine handy, shake salt onto the stain and dab with club soda. Can also blot the stain with one tsp of mild detergent mixed with one cup warm water followed by 1/3 cup white vinegar and 2/3 cup water. Finish gy sponging spot with clean water.

- Q:I have a section of cloth I would to fade, which I believe is a cotton/polyester blend. Sun fading has proven useless. Is there any other way to safely fade the cloth without making it form irregularities or patches?

- Soak the whole thing in bleach water.

- Q:According to Genesis, women must experience painful childbirth to pay for the crimes of Eve. Does modern medicine go against God‘s plan?

- I use one that I bought from Cabela's that has a 500lb capacity, 16 inch puncture proof wheels and has carried out 2 deer at one time that weighed over 300 lbs. I have pulled it behind my 4 wheeler, skidded it over logs and it has performed perfectly. It cost under $150 You can't buy the materials and build one that cheaply.Check it out- It's the super magnum cart.

- Q:How expensive is it and how reliable is the repair?

- Chad: The word blister is the last thing you want to hear. We had some on our Pearson 28'. They can be ground out and gel coat reapplied. Depending on how severe the blistering is. It certainly doesn't mean the vessel is ruined. Water has found a way to seep between the gelcoat and paint. Just make sure you find a competent mechanic for the repair.

- Q:We found out the hard way that polymer based resins melt right through EPS, so we are going to use epoxy based resin. I have never fiberglassed anything before. I kind of got the picture from Googling that it is kind of like using paper mache, coat the foam in epoxy put the fiberglass cloth over it and paint epoxy into the cloth. Is this the way to do it?

- problematic task. do a search into google. this can assist!

- Q:How do you remove fingernail polish from carpet/clothing?

- If you ever figure it out, please let me know! My sister spilled nail varnish on her carpet once - I moved into the room aged about 8 and the stain was still there when I moved out about 12 years later. My Mum must know all the tricks (her father worked in carpets his whole life), but that one had her stumped. Good luck xx

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

FRP Pultrusion Profile Cable Tray with High Quality

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m

- Supply Capability:

- 100000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords