Composite Fiber Glass Pipe Pultruded FRP Fiberglass Round Pipe (RP)

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 20000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

PRODUCT DESCRIPTION

FRP Pipe, a wide range of fittings as elbows, reducers, tees, caps, flanges etc. is available.

Fittings are manufactured by the hand lay-up, contact molding and spray-up process. In hand lay-up and contact molding processes veil and alternate layers of mat and woven roving saturated with resin are applied on the mold. In spray-up process continuous strand roving is fed through a chopper gun, combined with catalyzed resin, and sprayed onto the mould surface.

FEATURES

High anti-corrosion capability, long designed service time of 20 years;

Less joints and rapid assembly design: According to concrete engineering conditions, there are a several ways of connection designed for clients to choose, which include Adhesive-bonded Plug Joint, Adhesive-bonded End-to-end Joint, Flange Joint, Plug Joint with O-ring Gasket(with key-lock) and Thread Joint etc.

Good electrical insulation

Not rust, rot or corrode, not permeate, and without consequent pollution;

Anti-furring and vermiculate resistance;

Flexible design: the pipe can be designed on the shape and function according to its conditions of usage.

TECHNICAL DATA

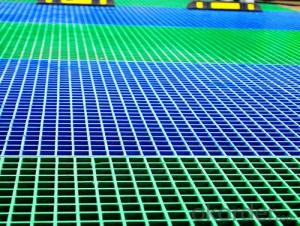

Thickness (mm) | Bar width (mm) | Open space (mm) | Open rate (%) | Approx weight (kg/m 2 ) |

25.4 | 15.2 | 22.8 | 60 | 13.2 |

25.4 | 15.2 | 15.2 | 50 | 15.9 |

25.4 | 15.2 | 10.1 | 40 | 18.5 |

25.4 | 40 | 10.8 | 21 | 14.5 |

38.1 | 15.2 | 22.8 | 60 | 15.8 |

38.1 | 15.2 | 15.2 | 50 | 19.1 |

38.1 | 15.2 | 10.1 | 40 | 22.4 |

50.8 | 25.4 | 25.4 | 50 | 16.6 |

50.8 | 25.4 | 12.7 | 33 | 21.1 |

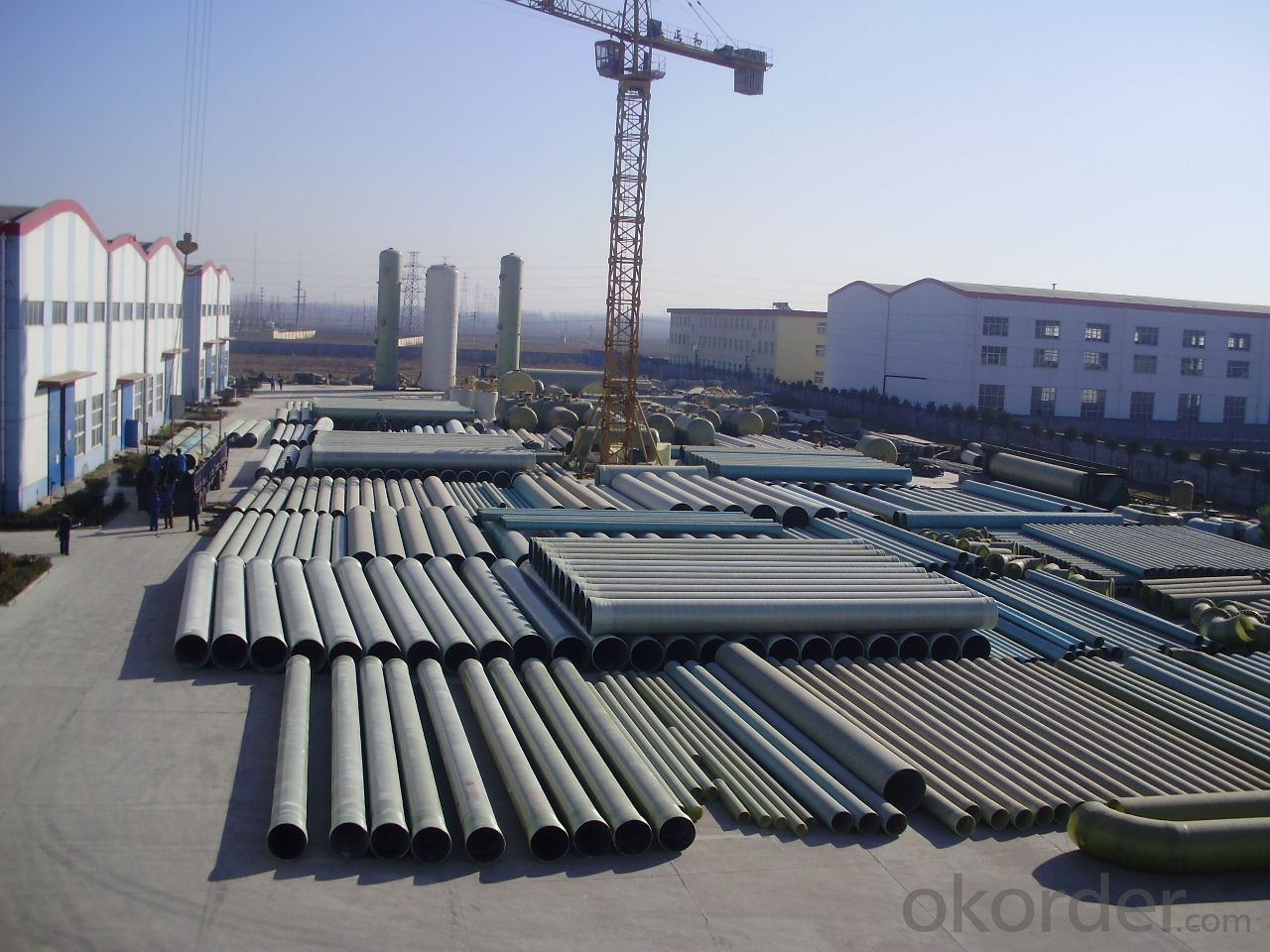

PICTURES

COMPANY INFORMATION

CNBM, China National Building Materials Group is a state-owned enterprise in charge of administrative affairs in china buiding materials industry. Established in 1984, CNBM is a large group corporation of building materials with total assets of 25 billion RMB and a total staff of 30,000.CNBM now owns 200 subordinating firms of solely owned and joint-venture companies.

CNBM International Corporation is one subsidiary of CNBM, we focus on offering good-quality products, professional service and complete solution to our customers. Strong delivery capacity, advanced technology & management, strong financing capability and excellent after-sale service are our advantages in sharing international market.

- Q: What are the differences between inorganic FRP pipes and plexiglass pipes, what are the advantages and disadvantages?

- Inorganic glass fiber reinforced plastic wind pipe: magnesium magnesite soil and glass fiber mesh cloth made of advantages: flame retardant shortcomings: large proportion, low strength

- Q: Raw material and mix ratio of inorganic glass fibre reinforced plastic wind pipe

- The general ratio is 1 to 0.001

- Q: CGCT what's the meaning of the GRP sand pipe?

- The pipeline in the design according to the use of pressure, stiffness and other conditions to determine the need for sand, if the thickness of the pipe can satisfy the pressure requirements and can meet the requirement of stiffness, is generally not the sand.

- Q: What are the specifications of glass fibre reinforced plastic cable pipes? What are they?

- FRP cable pipe is a new type of composite material, it mainly resin as adhesive, glass fiber as reinforcing agent, quartz sand as the supplementary material, formed by microcomputer control winding machine manufacturing, it has the strength of resistance to high pressure, weight, easy installation, safe and reliable, strong performance of insulation, corrosion can be anti corrosive the items, the anti parameter Water Leakage ability, but also has the advantages of long service life, can reach more than 50 years, because the FRP cable protection pipe set has various advantages of the industry, the performance has exceeded the same industry plastic pipe performance, it becomes popular industry engineering personnel.

- Q: What's the price of fiberglass reinforced sand pipes?

- It must be different. It costs a lot of freight, so I suggest buying it locally. Henan is in Henan.

- Q: Which is better, pultruded FRP square pipe with PVC?

- When abrasive materials are transported in the wear-resistant pipes (such as ash, coal dust, ore fines, etc.), there is a problem of rapid wear and tear of the wear-resistant pipes, especially the rapid wear of the bent pipe.

- Q: How to prevent the glass fiber reinforced plastic pipe from being damaged by aging or over pressure, causing the liquid to splash and hurt people

- If you are afraid of the glass tube will be such a question, the weak links or parts of the local reinforcement, the conditions can, can re pipe liner, to compression, anti ageing effect

- Q: Can FRP pipes be used in heating pipes?

- Glass steel pipe road does not belong to common heating pipe material.Heating pipe requirements are solid, high temperature, pressure, easy connection, convenient construction.Usually, heating pipes are made of steel and materials are more common.

- Q: What is the thickness of all types of FRP pipes?

- The standard effective length of the tube is 6m and 12M, and the production methods include fixed length winding process, centrifugal casting process and continuous winding process of three kinds. Classification can be carried out according to the product process method, pressure grade PN and stiffness grade SN.

- Q: What are FRP pipes used for making? What raw materials?

- So people began to think, if you can make a kind of glass has both hardness, high temperature resistance, corrosion resistance of the nature, but also with steel as hard, not broken characteristics, then this material will be of great use. People have made such a composite material after research and experiment. It is a glass pipe and steel, can stand shoulder to shoulder.

Send your message to us

Composite Fiber Glass Pipe Pultruded FRP Fiberglass Round Pipe (RP)

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 20000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords