Composite Pipes FRP Grating Pultruded Grating GRP Grating High Quality Fiberglass Grating

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 5000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of FRP Grille Description

FRP Grating is a structural panel which uses high-strength E-Glass roving as reinforcing material, thermosetting resin as matrix and then casted and formed in a special metal mold. It provides properties of light weight, high strength, corrosion resistance, fire resistance and anti-skid. FRP Molded Grating is widely used in oil industry, power engineering, water & waste water treatment, ocean survey as working floor, stair tread, trench cover, etc. and is an ideal loading frame for corrosion circumstances.

2. Main Features of FRP Grille

1) Light Weight & High Strength

The perfect combination of the continuous E-glass roving and thermosetting polyester resin provide grating with light weight and high strength and its specific gravity is only 1/4 of that of steel, 1/3 of aluminum. Its rigidity is up to and even exceeds that of steel. Different thickness and mesh size bring the client more choice.

2) Electrical Insulating

High strength E-glass roving and high-grade resin provide the product super electric performance. Its electric break strength could reach 10KV/mm. There is no electric spark even when impact by tools, meanwhile it is non-magnetism. FRP Molded Grating could be used safely under the antiknock, diamagnetism and electric-resistance environments.

3) Aging Resistance

The high-grade resin and anti-ageing stabilizer provide grating long-life ageing resistant performance and the unique design make grating excellent self-cleanness function and keep its brightness and strength over a long time. The service life of grating could be 25 years

4) Safety & Anti-slip

The high modulus of elasticity and various surfaces provided the super anti-skid performances. Its surface could be smooth surface, meniscus surface, grit surface and chequer plate cover which is suitable for different working places.

5) Corrosion Resistance

Different types of resin provide their own different anti-corrosion properties, which could be used in different corrosion circumstance such as acid, alkali, salt, organic solvent (in gas or liquid form) and the like over a long period.

6) Fire Resistance

Our special formula provide grating with excellent fire resistant performance.

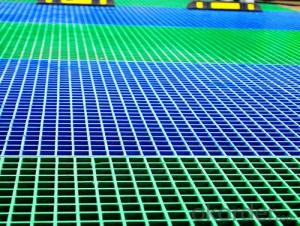

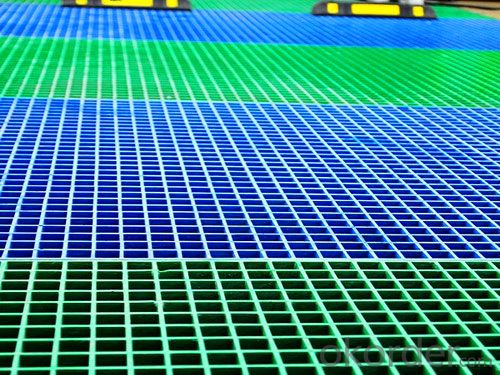

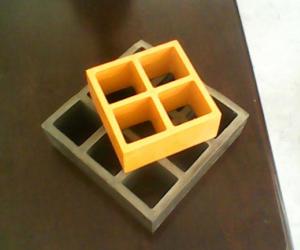

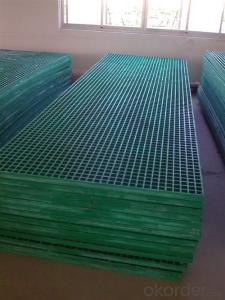

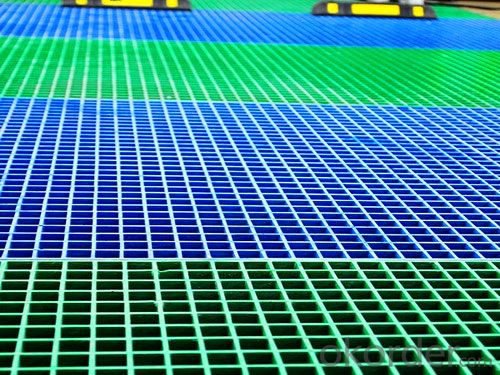

3. FRP Grille Images

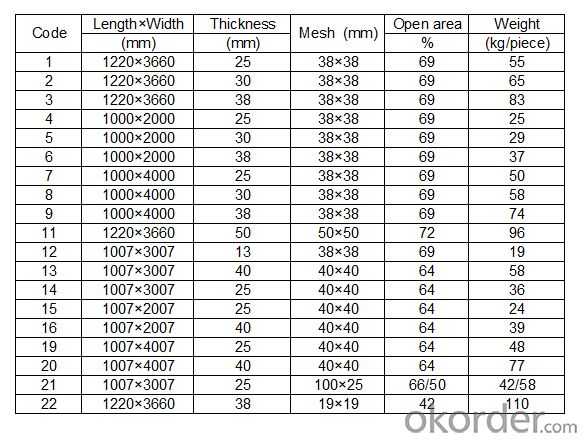

4. FRP Grille Specification

5. FAQ of FRP Grille

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

One of the leading manufacturers and suppliers specializing in FRP products in China. The integrated sales & service ensures customers with various demands an easier access for purchasing management.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible.

- Q: Designed to support FRP pipes, is it m or mm?

- Glass fiber reinforced plastic cable protection tube, a resin based, continuous glass fiber reinforced fabric as reinforced material, through computer control, winding process or pultrusion process of forming a pipeline. The glass steel production process, high strength, good toughness, electrical insulation, flame retardant, good heat resistance, can not deform, at 100 degrees high temperature corrosion resistance, erosion resistance and long service life, acid salt and various organic solvents with corrosive media, with a life span of 50 years. Applicable to a wide range of glass for cable laying underground steel cable protection tube, play a protective role, but also can be used for cable bridge, stone and of high demand

- Q: CGCT what's the meaning of the GRP sand pipe?

- The pipeline in the design according to the use of pressure, stiffness and other conditions to determine the need for sand, if the thickness of the pipe can satisfy the pressure requirements and can meet the requirement of stiffness, is generally not the sand.

- Q: Is it possible to touch the water when the glass fiber reinforced plastic pipe is polished?

- For nearly 20 years of brand silicone mold manufacturers, steel and glass also played nearly 20 years, glass steel pipe interface after grinding with water is Never mind, can be polished with water to the point where you can proceed to the next step of the operation of the glass steel bonding with a clean cotton cloth to wipe clean.

- Q: Who knows, how is the glass reinforced septic tank connected with the municipal pipe?

- Septic tank (Hu, F, NCH) is the treatment of nightsoil and to filter precipitation equipment. The principle is that the cured material decomposes at the bottom of the tank, and the upper hydration object flows into the pipeline to prevent the pipe from clogging and has enough time to hydrolyze the solidified object (such as excrement and urine). Tank (septic) refers to the division of living sewage sludge, and anaerobic digestion of sludge structure of small structures.

- Q: What are the construction methods of glass fiber reinforced plastic paint anticorrosive pipes?

- Oil and gas pipelines used for twenty years, basically no corrosion phenomenon. As part of a group of coal tar epoxy primer and topcoat are based on epoxy resin and coal tar as the main film-forming material, add a variety of anti rust paint, insulating filler, toughening agent, leveling agent, diluent, anti settling agents and other materials, the B component is modified amine curing agent or curing agent the main material, adding fillers. When the product is sold, the A and B parts are supplied together, and the mixture is mixed in proportion during construction.

- Q: How many times can the temperature withstand of FRP winding pipes? What are the factors?!

- FRP coil pipe:(1) corrosion resistance: chemically inert material, excellent corrosion resistance, and can choose different corrosion resistant pipes according to the transmission medium.(2) strong mechanical strength: good water pressure resistance, good resistance to external pressure and impact strength, and piping and fittings can be designed according to the required pressure.(3) temperature adaptability: the use of temperature range: greater than -70 degrees Celsius, less than 250 degrees Celsius, under the freezing medium, the pipe is not split. (4) the resistance of the fluid is small: the pipe wall is smooth, the roughness coefficient is 0.0084, and the pipe diameter can be reduced under the same flow rate.(5) light weight, long life: light quality, convenient transportation, low construction cost, no maintenance, and the service life of more than 50 years.(6) maintain the water quality: non-toxic, conveying drinking water, can maintain long-term water quality sanitation.

- Q: Can FRP pipes be used in heating pipes?

- FRP pipes are generally not used in heating pipes, because the use temperature of FRP pipes is limited, as detailed below:1. universal unsaturated polyester FRP can only be used for less than or equal to 60 degrees (HG/T20696-1999)2. bisphenol A unsaturated polyester FRP can only be used for less than or equal to 100 degrees HG/T20696-1999)3. vinyl unsaturated polyester glass fiber can only be used for less than or equal to 120 degrees HG/T20696-1999)4. epoxy FRP can be used for less than or equal to 90 degrees HG/T20696-1999)5. glass fiber reinforced plastic sand holding pipes can only be used for less than or equal to 50 degrees (GB/T21238-2007)

- Q: Uneven settlement of the foundation, can lead to glass fiber reinforced plastic underground water pipes burst, what is the principle?

- Can cause rupture. FRP material originally resistant to pressure better, tensile, shear resistance is poor, the foundation sinking is shear, I want to sink more than 5 cm, if the soil around the pipeline is compacted, it may break

- Q: What are the main points for the installation of FRP ducts?

- All you can think of public places, shopping malls, residential buildings, enterprises, institutions, etc., and so on, as long as the money, that can be installed

- Q: What are FRP pipes used for making? What raw materials?

- The glass tube with its unique strong corrosion resistance, smooth surface materials, low energy consumption and long service life (50 years), convenient transportation and installation, maintenance and many other advantages of low cost and low cost in electric power, petroleum, chemical industry, papermaking, city water supply and drainage, sewage treatment plant, seawater desalination, gas transportation other industries have been widely applied.

Send your message to us

Composite Pipes FRP Grating Pultruded Grating GRP Grating High Quality Fiberglass Grating

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 5000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords