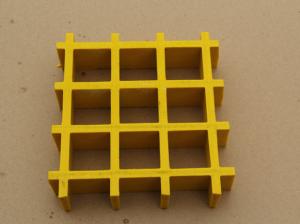

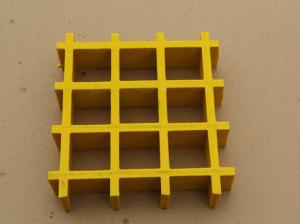

FRP Pultrusion Profiles - Fiberglass Reinforced Plastic FRP Pultruded Floor Grating

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m

- Supply Capability:

- 50000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description

Pultruded grating is made by a particular assembly process, which using “I” shape as its main load-bearing and special rod to go through the bearing bar. Pultruded grating include the standard grating and the custom grating, the custom grating can be designed to meet customer’s requirement or special using condition by changing the shape, size and space of the bearing bars, the surface can be covered with lozenge panel, grit panel, or added the anti-slippery sand directly.

FRP pultruded grating has the most characteristics of molded grating, but it has its distinct advantages, it has very high fiberglass content in the loading direction, so it has very high load capability, it has more superiority when used at wide span, so that the basic support will be decreased and the project cost will be reduced accordingly.

FRP Fitting,a wide range of fittings as elbows, reducers, tees, caps, flanges etc. is available.

Fittings are manufactured by the hand lay-up, contact molding and spray-up process. In hand lay-up and contact

molding processes veil and alternate layers of mat and woven roving saturated with resin are applied on the

mold. In spray-up process continuous strand roving is fed through a chopper gun, combined with catalyzed

resin, and sprayed onto the mould surface.

Features

a. Anti-corrosion and anti-rust

b. Light weight and high strength

c. Anti-flammable

d. Anti- fatigue

e. Safe and anti-slippery

f. Anti-ageing

g. Easy of maintenance

h. Excellent electromagnetism property

i. Good economic benefit

Parameter Table

The standard space between two crossbars is 6 inch or 12 inch.

Thickness (mm) | Bar width (mm) | Openspace (mm) | Open rate (%) | Approx weight (kg/m 2 ) |

25.4 | 15.2 | 22.8 | 60 | 13.2 |

25.4 | 15.2 | 15.2 | 50 | 15.9 |

25.4 | 15.2 | 10.1 | 40 | 18.5 |

25.4 | 40 | 10.8 | 21 | 14.5 |

38.1 | 15.2 | 22.8 | 60 | 15.8 |

38.1 | 15.2 | 15.2 | 50 | 19.1 |

38.1 | 15.2 | 10.1 | 40 | 22.4 |

50.8 | 25.4 | 25.4 | 50 | 16.6 |

50.8 | 25.4 | 12.7 | 33 | 21.1 |

Pictures

- Q: Are FRP pultrusion profiles resistant to oil and grease?

- Yes, FRP pultrusion profiles are highly resistant to oil and grease due to the inherent properties of the fiberglass reinforcement used in their construction. The composite material offers excellent chemical resistance, making it suitable for applications where exposure to oil and grease is expected.

- Q: Can FRP pultrusion profiles be used in the construction of railway sleepers?

- Yes, FRP pultrusion profiles can be used in the construction of railway sleepers. FRP (Fiber Reinforced Polymer) offers high strength, durability, and corrosion resistance, making it a suitable material for railway applications. The pultrusion process ensures consistent quality and allows for the customization of profiles to meet specific requirements. Additionally, FRP pultrusion profiles are lightweight and have excellent electrical insulation properties, making them an ideal choice for railway sleepers.

- Q: Can FRP pultrusion profiles be used in the construction of shipping containers?

- Indeed, the utilization of FRP pultrusion profiles in the construction of shipping containers is possible. These profiles offer numerous advantages that render them suitable for this purpose. To begin with, FRP pultrusion profiles possess exceptional strength and durability. They exhibit a high strength-to-weight ratio, enabling the creation of lightweight shipping containers capable of withstanding heavy loads and harsh environmental conditions. This characteristic proves particularly advantageous in the shipping industry, where containers endure rough handling and extreme weather while in transit. Furthermore, FRP pultrusion profiles display resistance to corrosion, a significant concern in the shipping industry due to exposure to saltwater and other corrosive substances. Unlike traditional materials like steel, FRP does not rust or corrode, thereby ensuring a longer lifespan for the shipping containers. Moreover, FRP pultrusion profiles exhibit excellent thermal insulation properties. This characteristic facilitates the maintenance of a consistent temperature within the shipping containers, which is crucial for transporting temperature-sensitive goods such as food, pharmaceuticals, and chemicals. Additionally, FRP pultrusion profiles can be easily customized and fabricated into various shapes and sizes, allowing for design flexibility in the construction of shipping containers. They can be molded to specific dimensions and incorporate features such as reinforcements, fastening points, and integrated insulation. Notably, FRP pultrusion profiles are also non-conductive and possess low thermal conductivity. These attributes make them an ideal choice for shipping containers that transport sensitive electronic equipment or hazardous materials, as they reduce the risk of electrical and thermal accidents. In conclusion, FRP pultrusion profiles can indeed be employed in the construction of shipping containers. Their strength, durability, corrosion resistance, thermal insulation properties, design flexibility, and non-conductive nature make them a reliable and practical choice for this application.

- Q: Are FRP pultrusion profiles resistant to fuels?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles are highly resistant to fuels. Due to their inherent corrosion resistance and non-reactive nature, FRP pultrusions can withstand exposure to a wide range of fuels, including gasoline, diesel, and aviation fuels, without deteriorating or losing their structural integrity. This makes them suitable for various applications in industries such as automotive, aerospace, and oil and gas, where resistance to fuel exposure is crucial.

- Q: Can FRP pultrusion profiles be used in agricultural structures?

- Agricultural structures can indeed utilize FRP pultrusion profiles. FRP pultrusion profiles, also known as Fiber Reinforced Polymer profiles, possess numerous advantages that render them suitable for agricultural purposes. To begin with, the corrosion resistance of FRP profiles is of utmost importance in the agricultural industry, given the exposure of structures to harsh environments and chemicals like fertilizers and pesticides. Unlike conventional materials such as steel or wood, FRP does not rust or decay, ensuring enduring performance in agricultural structures. Furthermore, FRP profiles are lightweight yet durable, facilitating easy handling and installation in agricultural applications. Their high strength-to-weight ratios enable efficient construction, thereby reducing the necessity for heavy machinery during the installation process. Moreover, FRP profiles exhibit exceptional mechanical properties, including high stiffness and impact resistance, which prove advantageous for agricultural structures subjected to heavy loads, vibrations, or machinery impact. In addition, FRP pultrusion profiles can be designed to resist UV radiation, thereby preventing degradation from prolonged exposure to sunlight. This quality makes them suitable for outdoor agricultural structures consistently exposed to the elements. Lastly, FRP profiles are non-conductive, a critical advantage in agricultural environments where electrical safety is paramount. This characteristic eliminates the risk of electrical hazards associated with conductive materials like steel. In summary, FRP pultrusion profiles offer a reliable and efficient solution for a variety of agricultural structures, such as greenhouse frames, livestock enclosures, irrigation systems, and storage facilities. Their corrosion resistance, lightweight nature, high strength, UV resistance, and non-conductivity make them an ideal choice for agricultural applications.

- Q: Can FRP pultrusion profiles be used in the construction of conveyor systems?

- FRP pultrusion profiles are highly effective in the construction of conveyor systems. They offer numerous advantages that make them suitable for this purpose. To begin with, these profiles are both lightweight and strong, making them ideal for constructing conveyor systems. Their high strength-to-weight ratio allows for easy installation and maintenance, reducing the overall weight of the system while maintaining structural integrity. This is particularly beneficial when designing and building long-span conveyor systems. Additionally, FRP pultrusion profiles are highly resistant to corrosion. Unlike traditional materials such as steel or aluminum, they do not rust or deteriorate when exposed to chemicals or moisture. This resistance makes them particularly suitable for conveyor systems that may be subjected to harsh environments or corrosive substances, such as those found in the mining or chemical industries. Another advantage of FRP pultrusion profiles is their excellent electrical insulation properties. They do not conduct electricity, which is essential in conveyor systems where electrical components are present. This property ensures a higher level of safety and reduces the risk of electrical hazards. Furthermore, these profiles can be easily customized to meet specific design requirements. They can be manufactured in various shapes and sizes, providing flexibility in conveyor system design. Additionally, they can incorporate features such as channels, slots, or reinforcements, which can be advantageous for mounting accessories or facilitating the movement of goods on the conveyor. Lastly, FRP pultrusion profiles are highly durable and have a long service life. They are resistant to UV degradation and do not require frequent maintenance or painting, resulting in reduced lifecycle costs compared to traditional materials. This durability makes them a cost-effective choice for constructing conveyor systems. In conclusion, FRP pultrusion profiles are an excellent option for constructing conveyor systems. Their lightweight nature, corrosion resistance, electrical insulation properties, customization options, and durability make them a reliable and efficient material for this application.

- Q: Will the FRP section crack for a long time?

- As long as the design of the structure is reasonable and the quality of the product conforms to the design requirements, the normal use shall not be cracked.

- Q: Can FRP pultrusion profiles be used in the construction of modular buildings?

- Modular buildings can utilize FRP (Fiber Reinforced Polymer) pultrusion profiles. These profiles possess various advantages that render them suitable for modular construction. To begin with, FRP pultrusion profiles are not only lightweight, but also highly durable and strong. This makes them perfect for modular buildings, where reducing weight is crucial for transportation and assembly. In fact, the strength-to-weight ratio of FRP pultrusion profiles often surpasses that of traditional construction materials like steel or concrete. Furthermore, these profiles are resistant to corrosion, chemicals, and weathering. This becomes particularly significant for modular buildings, as they may face different environmental conditions during transportation and on-site assembly. The corrosion resistance also guarantees the longevity and durability of the modular building. Moreover, FRP pultrusion profiles can be designed to possess excellent thermal insulation properties. This proves advantageous for modular buildings that prioritize energy efficiency, as it helps minimize heating and cooling costs. Additionally, these profiles are easily shaped and customized to meet the specific requirements of the modular building design. This versatility allows for the creation of intricate and complex structural components, thereby facilitating the modular construction process. Furthermore, FRP pultrusion profiles are non-conductive, which enhances safety in modular buildings. Their inability to conduct electricity makes them appropriate for applications necessitating electrical insulation. In conclusion, FRP pultrusion profiles offer a viable choice for constructing modular buildings due to their lightweight, durability, corrosion resistance, thermal insulation properties, versatility, and non-conductive nature. These attributes make FRP pultrusion profiles a reliable and efficient solution for modular construction projects.

- Q: Can FRP pultrusion profiles be used in the construction of modular storage systems?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in the construction of modular storage systems. These profiles offer high strength-to-weight ratio, corrosion resistance, and durability, making them suitable for supporting heavy loads and ensuring long-term performance in storage applications. Additionally, their modular nature allows for easy assembly and customization, making them a viable option for constructing versatile and efficient storage systems.

- Q: Can FRP pultrusion profiles be used in chemical storage tanks?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in chemical storage tanks. FRP pultrusion profiles are known for their excellent corrosion resistance, making them suitable for storing a wide range of chemicals. They are also lightweight, strong, and have a high strength-to-weight ratio, which makes them an ideal choice for constructing durable and long-lasting chemical storage tanks. Additionally, FRP pultrusion profiles can be customized to meet specific design requirements, allowing for flexibility in tank design and construction. Overall, FRP pultrusion profiles are a reliable and cost-effective option for chemical storage tanks due to their corrosion resistance, strength, and customization capabilities.

Send your message to us

FRP Pultrusion Profiles - Fiberglass Reinforced Plastic FRP Pultruded Floor Grating

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m

- Supply Capability:

- 50000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords