FRP Pultrusion Profiles - GRP/FRP Plastic Pultruded Grating Fiberglass Floor Panels

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m

- Supply Capability:

- 80000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

PRODUCT DESCRIPTION

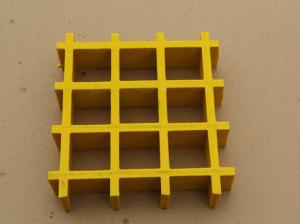

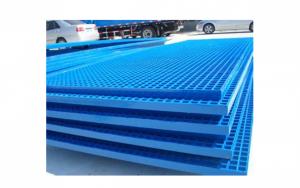

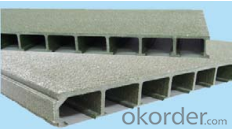

FRP flooring panel is a big size profile which is made by pultrusion technology and in holistic shape, it could form a continuours close plane by unique self-lock structure,which could be used as load structures in various corrosion environments and could replace wood plate, aluminum plate or steel plate etc.

The product could add natural color grit on the surface,which is safe for the anti-slippery,besides it could obtain the natural appearance and no fadding for a long time.

Deck of cooling tower, plate of scaffold, floor of chip manufacturing, deck of bridge, rooftop, slope of architectural overhaul, structural floor, floor of light railcar, baffle of equipment, roof of cover, trench cover, footpath, weather plank.

FEATURES

a. anti-corrosion, non-rusty

b. lightweight and high strength

c. anti-flammable

d. anti-fatigue

e. anti-slippery and safety

f. anti-ageing

g. easy to installation and maintenance

h. excellent electromagnetism property

SPECIFICATION

Item No. | Height(mm) | Mesh Size(mm) | Standard Panel Size | Open Area | Weight(kg/m2) |

1 | 15 | 38 × 38 | 1220 × 3660 | 72% | 6.00 |

2 | 15 | 20 × 20 | 1247×4047,1007×4047 | 42% | 9.00 |

3 | 25 | 38 ×38 | 997 × 3050 , 1220 × 3660 | 69% | 12.32 |

4 | 25 | 40 × 40 | 1007 × 3007, 1007 × 4007, | 67% | 12.20 |

5 | 25 | 25 × 100 | 1009 × 3007 ,1209 ×3657 | 67% | 13.87 |

6 | 30 | 38 × 38 | 1220 × 3660 , 997 × 3050 | 69% | 14.60 |

7 | 30 | 40 × 40 | 1007 × 3007 , 1007 × 4007 | 67% | 14.28 |

8 | 30 | 20 × 20 | 1000 × 4000,1247×4047 | 42% | 18.10 |

9 | 38 | 38 × 38 | 997 × 3050 , 1220 × 3660 | 68% | 19.71 |

10 | 38 | 25 × 152 | 1226 × 3665 (Bearing bars to run length direction) | 56% | 22.40 |

11 | 38 | 20 × 20 | 1007 × 4007,1247×4047 | 42% | 22.50 |

12 | 40 | 40 × 40 | 1007 × 3007 ,1007 × 4007, 1007 × 4047 ,1247 × 4047 | 67% | 19.87 |

13 | 40 | 20 × 20 | 1247 × 4047 | 42% | 23.70 |

14 | 50 | 50.7 × 50.7 | 1225× 3660 | 69% | 22.17 |

15 | 60 | 38 × 38 | 1220 × 3660 | 47% | 50.43 |

16 | P38 | 38 × 38 | 1230 × 3670 | 68% | 17.5 |

17 | P30 | 38 × 38 | 1220 × 3660 | 69% | 14.0 |

PICTURES

- Q: How are FRP pultrusion profiles manufactured?

- FRP pultrusion profiles are manufactured through a highly controlled and precise process. The manufacturing process involves several steps. Firstly, the raw materials are selected, which usually include reinforcing fibers such as fiberglass, carbon fiber, or aramid, and a thermosetting resin matrix. These materials are chosen based on the desired mechanical properties of the final product. Next, the reinforcing fibers are impregnated with the resin matrix. This is typically done by passing the fibers through a bath of resin or using a resin injection system, ensuring that the fibers are completely saturated and coated. Once the impregnation is complete, the fibers are carefully pulled through a heated steel die. The die is designed to shape the pultrusion profile and provide the desired cross-sectional shape. The die is heated to a temperature that activates the resin's curing process, allowing it to harden and bond the fibers together. As the fibers pass through the die, they are continuously pulled by a set of pulling rollers or a gripper system. This pulling force helps maintain the profile's shape and dimensions and ensures a consistent and uniform product. After exiting the die, the profile enters a cooling zone, where it is cooled down using either air or water. This rapid cooling helps set the resin and stabilize the shape of the profile. Finally, the cured and cooled profile is cut to the desired length, often using automated cutting systems. Additional finishing processes like surface treatment, sanding, or painting may be applied to meet specific requirements or enhance the profile's aesthetics. Overall, the manufacturing process for FRP pultrusion profiles combines the impregnation of reinforcing fibers with resin, the shaping of the profile through a heated die, and the curing and cooling steps. This process allows for the production of high-strength, lightweight, and corrosion-resistant profiles that find applications in various industries, including construction, aerospace, automotive, and electrical.

- Q: What are the different shapes and sizes of FRP pultrusion profiles available?

- FRP (Fiber Reinforced Polymer) pultrusion profiles are available in a wide range of shapes and sizes to cater to various applications and industries. Some of the commonly available shapes include: 1. Square and rectangular profiles: These profiles are available in different sizes and are widely used in construction, infrastructure, and industrial applications. They offer excellent structural strength and can be used as beams, columns, or other load-bearing elements. 2. Round profiles: Round FRP pultrusion profiles are often used as structural supports, handrails, and guardrails. They are available in various diameters to suit different requirements. 3. I-beams: FRP I-beams are popular in the construction industry due to their high strength-to-weight ratio. They are often used as structural members, supporting elements, or floor joists. 4. Channel profiles: Channel-shaped FRP profiles are used for applications that require a combination of strength and versatility. They find applications in cable trays, equipment supports, and framing systems. 5. Angle profiles: FRP angle profiles are commonly used as reinforcements or supports in construction and industrial settings. They provide stability and structural integrity to various components. 6. Custom profiles: Apart from the standard shapes mentioned above, FRP pultrusion profiles can also be customized to meet specific requirements. Manufacturers can create profiles with unique shapes and sizes to suit the needs of different applications. It is important to note that the availability of shapes and sizes may vary among manufacturers. Therefore, it is advisable to consult with suppliers or manufacturers to determine the specific range of FRP pultrusion profiles they offer.

- Q: Are FRP pultrusion profiles resistant to high winds or hurricanes?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles are highly resistant to high winds and hurricanes. FRP is a composite material that combines the strength of fiberglass with the durability of polymers. This results in a lightweight yet incredibly strong material that can withstand extreme weather conditions. FRP pultrusion profiles have been extensively tested and have proven to have excellent wind resistance properties. They have a high stiffness-to-weight ratio, allowing them to withstand the forces exerted by high winds without bending or breaking. Additionally, the inherent flexibility of FRP allows it to absorb and distribute the forces exerted by wind, reducing the risk of damage. In the case of hurricanes, FRP pultrusion profiles have demonstrated their ability to withstand the strong winds and flying debris associated with these severe weather events. They have been used in various applications such as building facades, bridges, and utility poles in hurricane-prone areas, with great success. Furthermore, FRP pultrusion profiles are corrosion-resistant, which is another advantage when it comes to withstanding high winds and hurricanes. Unlike traditional materials like steel or wood, FRP profiles do not rust or rot when exposed to moisture, making them even more suitable for these challenging weather conditions. Overall, due to their high strength, durability, flexibility, and corrosion resistance, FRP pultrusion profiles are an excellent choice for applications where resistance to high winds or hurricanes is required.

- Q: How do FRP pultrusion profiles perform in extreme temperatures?

- FRP pultrusion profiles generally perform well in extreme temperatures due to their inherent thermal stability and resistance to temperature variations. The material's composition, typically made of reinforced fibers and polymer resin, allows it to maintain its structural integrity and mechanical properties across a wide range of temperatures. This makes FRP pultrusion profiles suitable for use in both extremely hot and extremely cold environments, as they are less prone to expansion, contraction, or degradation compared to other materials.

- Q: Are FRP pultrusion profiles fire resistant?

- FRP pultrusion profiles exhibit excellent fire resistance due to the combination of reinforcing fibers and the polymer matrix employed in their production. These profiles are crafted through the pultrusion process, wherein reinforcing fibers like fiberglass or carbon fiber are impregnated with a thermosetting resin. This resin undergoes a curing process, resulting in a robust and durable composite material. One of the primary advantages of FRP pultrusion profiles lies in their inherent fire resistance. The thermosetting resin utilized in their manufacture possesses properties that render it highly impervious to fire. When subjected to flames or elevated temperatures, the resin does not easily burn or melt, thereby impeding the propagation of fire. Moreover, the reinforcing fibers present in FRP profiles contribute significantly to their fire resistance. For example, fiberglass, being an inorganic substance, does not combust. It serves as a heat transfer barrier, aiding in the containment of flames. Additionally, FRP pultrusion profiles can be engineered to meet specific fire safety standards and regulations. By incorporating supplementary fire retardant additives or employing specialized resin systems, the fire resistance of these profiles can be further enhanced. It is crucial to note that although FRP pultrusion profiles do possess fire resistance, their precise fire rating may vary depending on the particular composition and design. Thus, it is imperative to consult manufacturers or suppliers who can furnish comprehensive information regarding the fire resistance properties of their FRP pultrusion profiles.

- Q: Are FRP pultrusion profiles resistant to fungal growth?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles are generally resistant to fungal growth. The composite materials used in pultrusion, such as resins and fibers, are inherently resistant to biological degradation, including fungal attack. The non-porous nature of FRP pultrusion profiles also makes it difficult for fungi to penetrate and grow on the surface. Additionally, the manufacturing process of pultrusion involves curing the composite materials at high temperatures, which further enhances their resistance to fungal growth. However, it is important to note that no material is completely immune to fungal growth under all conditions. Factors such as high humidity, prolonged exposure to moisture, and poor maintenance practices may still contribute to fungal growth on FRP pultrusion profiles, although to a lesser extent compared to other materials like wood or metal. Regular inspection and proper cleaning can help maintain the fungal resistance of FRP pultrusion profiles over their lifespan.

- Q: Are FRP pultrusion profiles resistant to fungal growth?

- Yes, FRP pultrusion profiles are highly resistant to fungal growth. The composite materials used in FRP pultrusion, such as fiberglass and resin, do not provide a suitable environment for fungi to grow. Additionally, the smooth surface of FRP profiles makes it difficult for fungi to attach and thrive. Hence, FRP pultrusion profiles are an excellent choice for applications where resistance to fungal growth is required.

- Q: Can FRP pultrusion profiles be used in the telecommunications industry?

- Indeed, the telecommunications industry can use FRP (Fiber Reinforced Polymer) pultrusion profiles. These profiles have numerous advantages that make them appropriate for telecommunications applications. Firstly, FRP pultrusion profiles are both lightweight and immensely strong, making them perfect for telecommunications infrastructure. They can be utilized in the design and construction of structures such as antenna mounts, support poles, cable trays, and enclosures. The lightweight nature of FRP profiles simplifies installation and maintenance, reducing the overall cost and effort involved in establishing and upkeeping telecommunications systems. Secondly, FRP pultrusion profiles possess exceptional corrosion resistance properties. This is especially crucial in the telecommunications industry, as infrastructure components are frequently exposed to harsh weather conditions and environmental factors. Unlike traditional materials like steel or aluminum, FRP profiles do not rust or corrode, guaranteeing their durability and dependability in telecommunications applications. Moreover, FRP pultrusion profiles provide electrical insulation properties, which are essential in the telecommunications industry. These profiles do not conduct electricity, making them suitable for applications requiring electrical grounding or isolation. This characteristic ensures the safety of telecommunications equipment and personnel. Furthermore, FRP pultrusion profiles can be tailored to meet specific project requirements. They can be engineered with specific dimensions, shapes, and load-bearing capacities as needed. This flexibility allows for the design and fabrication of telecommunications infrastructure that meets the unique demands of each project. In conclusion, FRP pultrusion profiles are well-suited for telecommunications applications due to their lightweight, high strength, corrosion resistance, electrical insulation properties, and customization options. These profiles offer a reliable and cost-effective solution for various applications within the telecommunications sector.

- Q: Can FRP pultrusion profiles be used in automotive applications?

- FRP pultrusion profiles can indeed be utilized in automotive applications, presenting a myriad of advantages that render them appropriate for such use. Firstly, these profiles possess the dual attributes of being lightweight and strong, which holds immense significance within the automotive industry. As weight reduction stands as a top priority for enhancing fuel efficiency and performance, the commendable strength-to-weight ratio of FRP profiles enables the creation of lighter vehicles that consume less fuel. Secondly, FRP pultrusion profiles exhibit exceptional corrosion resistance, a vital characteristic for automotive applications routinely encountering exposure to various chemicals, moisture, and harsh environments. This corrosion resistance ensures the long-term dependability and durability of the profiles, ultimately reducing maintenance expenses and prolonging the lifespan of automotive components. Moreover, FRP pultrusion profiles offer remarkable design flexibility, thereby facilitating the formation of intricate shapes and geometries that can be customized to meet specific automotive requirements. This flexibility allows for the seamless integration of FRP profiles into numerous automotive components, including body panels, structural supports, interior trims, and suspension parts. Additionally, FRP pultrusion profiles demonstrate high fatigue resistance, a crucial aspect for automotive applications that involve repetitive loading and vibrations. The fatigue resistance of FRP profiles guarantees their enduring performance and aids in averting failures and breakdowns. Lastly, FRP pultrusion profiles are non-conductive, an advantageous attribute in automotive applications necessitating electrical isolation. This property obviates the necessity for supplementary insulation and mitigates the risk of electrical failures and short circuits. All in all, the amalgamation of lightweightness, robustness, corrosion resistance, design flexibility, fatigue resistance, and electrical non-conductivity renders FRP pultrusion profiles suitable for diverse automotive applications, thereby contributing to enhanced performance, fuel efficiency, durability, and safety within the automotive industry.

- Q: Can FRP pultrusion profiles be used in the aerospace and aviation industry?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in the aerospace and aviation industry. FRP pultrusion profiles offer exceptional strength-to-weight ratio, corrosion resistance, and design flexibility, making them suitable for various applications in this industry. One of the key advantages of FRP pultrusion profiles is their high strength-to-weight ratio. This means that they can provide the required structural integrity while keeping the weight of the components low, which is crucial in aerospace and aviation applications where weight reduction is a priority. The lightweight nature of FRP profiles can contribute to fuel efficiency, improved performance, and increased payload capacity. Additionally, FRP pultrusion profiles exhibit excellent resistance to corrosion, including resistance to chemicals, moisture, and UV radiation. This makes them highly suitable for use in aircraft and aerospace systems, where exposure to harsh environmental conditions is common. Unlike traditional metallic materials, FRP profiles can withstand corrosive agents and maintain their structural integrity for extended periods, reducing maintenance requirements and enhancing the durability of aircraft components. Furthermore, the design flexibility of FRP pultrusion profiles allows for the creation of complex shapes and geometries, enabling engineers to tailor the profiles to meet specific requirements. This versatility in design opens up opportunities for innovative solutions in aerospace and aviation applications, such as structural components, aircraft interiors, radomes, fairings, and more. It is worth mentioning that FRP pultrusion profiles have been successfully used in the aerospace and aviation industry for various applications, including wing spars, stabilizers, galleys, interior panels, and cargo containers. Their proven track record demonstrates their reliability and performance in demanding environments. Overall, FRP pultrusion profiles are well-suited for use in the aerospace and aviation industry due to their high strength-to-weight ratio, corrosion resistance, and design flexibility. Their use can contribute to lighter, more efficient, and durable aircraft components, making them a viable choice for various applications in this sector.

Send your message to us

FRP Pultrusion Profiles - GRP/FRP Plastic Pultruded Grating Fiberglass Floor Panels

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m

- Supply Capability:

- 80000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords