FRP Pultrusion Profiles Molded Gratings - Fiberglass & Plastic Grating Flooring

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction

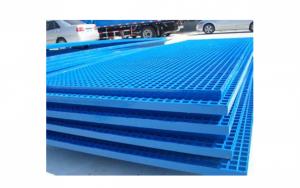

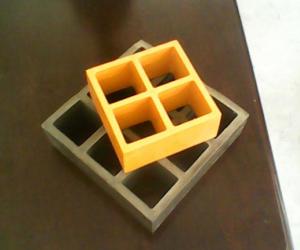

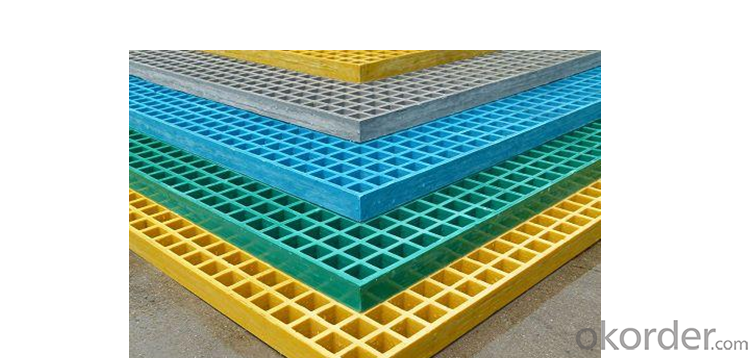

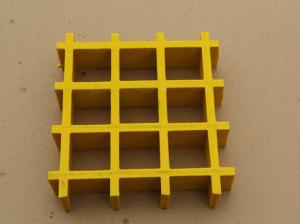

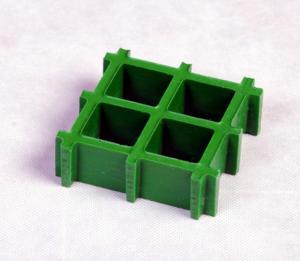

FRP Molded Grating is a structural panel which uses high-strength E-Glass roving as reinforcing material, thermosetting resin as matrix and then casted and formed in a special metal mold. It provides properties of light weight, high strength, corrosion resistance, fire resistance and anti-skid. FRP Molded Grating is widely used in oil industry, power engineering, water & waste water treatment, ocean survey as working floor, stair tread, trench cover, etc. and is an ideal loading frame for corrosion circumstances.

Feature

Corrosion Resistance

- Electrical Insulating

Aging Resistance

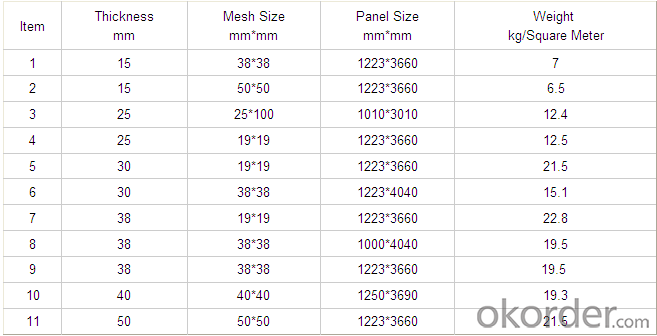

Specification

Advantage

coated with prevent aging layer

excellent insulating performance

- easy installation

Application

- Corrosive chemical industry equipment around the fence

All kinds of building maintenance section

FAQ

1. How's the payment?

Telegraphic Transfer(T/T) or Letter of Credit(L/C)

2. Do You Arrange Shipment?

Yes, dear esteemed customers, for FOB or CIF price, we will arrange shipment for you. For EXW price, clients need to arrange shipment by themselves or their agents.

3. How is the package?

Usually, we arrange the standard out-package for exporting.

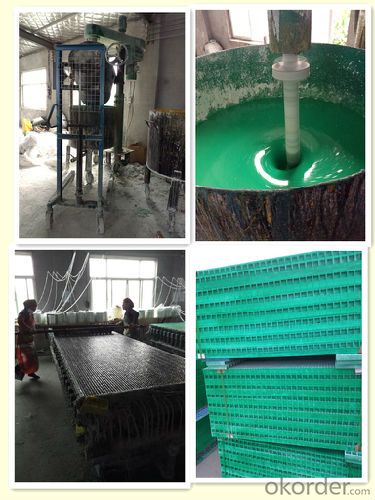

PROCESS

FACTORY

- Q: How are FRP pultrusion profiles manufactured?

- FRP pultrusion profiles are manufactured through a highly controlled and precise process. The manufacturing process involves several steps. Firstly, the raw materials are selected, which usually include reinforcing fibers such as fiberglass, carbon fiber, or aramid, and a thermosetting resin matrix. These materials are chosen based on the desired mechanical properties of the final product. Next, the reinforcing fibers are impregnated with the resin matrix. This is typically done by passing the fibers through a bath of resin or using a resin injection system, ensuring that the fibers are completely saturated and coated. Once the impregnation is complete, the fibers are carefully pulled through a heated steel die. The die is designed to shape the pultrusion profile and provide the desired cross-sectional shape. The die is heated to a temperature that activates the resin's curing process, allowing it to harden and bond the fibers together. As the fibers pass through the die, they are continuously pulled by a set of pulling rollers or a gripper system. This pulling force helps maintain the profile's shape and dimensions and ensures a consistent and uniform product. After exiting the die, the profile enters a cooling zone, where it is cooled down using either air or water. This rapid cooling helps set the resin and stabilize the shape of the profile. Finally, the cured and cooled profile is cut to the desired length, often using automated cutting systems. Additional finishing processes like surface treatment, sanding, or painting may be applied to meet specific requirements or enhance the profile's aesthetics. Overall, the manufacturing process for FRP pultrusion profiles combines the impregnation of reinforcing fibers with resin, the shaping of the profile through a heated die, and the curing and cooling steps. This process allows for the production of high-strength, lightweight, and corrosion-resistant profiles that find applications in various industries, including construction, aerospace, automotive, and electrical.

- Q: How do FRP pultrusion profiles perform in corrosive gas environments?

- FRP (Fiber Reinforced Plastic) pultrusion profiles have excellent performance in corrosive gas environments. The unique properties of FRP, such as high corrosion resistance, make them highly suitable for applications where exposure to corrosive gases is a concern. FRP pultrusion profiles are typically made from a combination of glass fibers and a resin matrix, such as polyester or vinyl ester. These materials are inherently resistant to corrosion and do not react with most corrosive gases. As a result, FRP pultrusion profiles can withstand exposure to a wide range of corrosive gases, including sulfur dioxide, hydrogen sulfide, chlorine, and many others. Moreover, FRP pultrusion profiles offer superior durability and long-term performance in corrosive gas environments. They do not rust, corrode, or degrade over time, unlike traditional materials like steel or aluminum. This corrosion resistance ensures that FRP profiles maintain their structural integrity even in harsh environments, reducing maintenance and replacement costs. Additionally, FRP pultrusion profiles can be manufactured with specific chemical-resistant resins and additives to enhance their performance in highly corrosive gas environments. This customization allows for tailoring the FRP profiles to meet the specific requirements of the application, ensuring optimal performance and longevity. Overall, FRP pultrusion profiles are an excellent choice for corrosive gas environments due to their exceptional corrosion resistance, long-term durability, and customization options. They provide a reliable and cost-effective solution for industries such as chemical processing, oil and gas, wastewater treatment, and many others where exposure to corrosive gases is a concern.

- Q: Can FRP pultrusion profiles be customized according to specific requirements?

- Yes, FRP pultrusion profiles can be customized according to specific requirements. Pultrusion is a manufacturing process that allows for the creation of complex shapes and sizes, making it possible to tailor the FRP profiles to meet specific design and performance criteria. This customization can include modifications in dimensions, reinforcement types, resin systems, color, surface finish, and various other parameters to ensure they meet the desired specifications and needs of the application.

- Q: How do FRP pultrusion profiles perform in electrical grounding systems?

- FRP pultrusion profiles perform well in electrical grounding systems due to their non-conductive properties. Unlike metal profiles, FRP profiles do not carry electrical current, making them a safe and effective choice for electrical grounding applications. Additionally, FRP profiles are corrosion-resistant, durable, and lightweight, making them a reliable and long-lasting option for grounding systems.

- Q: Can FRP pultrusion profiles be used in wastewater treatment facilities?

- Yes, FRP pultrusion profiles can be used in wastewater treatment facilities. FRP (Fiber Reinforced Plastic) pultrusion profiles are known for their high strength, corrosion resistance, and durability, making them suitable for various applications, including in harsh environments like wastewater treatment facilities. These profiles can be used for constructing structures, such as walkways, handrails, grating, and tanks, as well as for reinforcing or replacing traditional materials, such as steel or concrete, in different components of the facility. The corrosion resistance of FRP pultrusion profiles ensures their longevity and reduces maintenance costs, making them a viable option for wastewater treatment facilities.

- Q: Can FRP pultrusion profiles be used in electrical or telecommunications applications?

- FRP pultrusion profiles have a wide range of applications in the electrical and telecommunications industries. These profiles are highly regarded for their exceptional electrical insulating properties, impressive strength-to-weight ratio, and resistance to corrosion. As a result, they are well-suited for various electrical and telecommunications purposes. When it comes to electrical applications, FRP pultrusion profiles can function as electrical insulators, cable trays, busbar supports, and electrical enclosures. They serve to insulate and safeguard against electrical shocks, making them a popular choice for replacing traditional materials like metal or wood. Moreover, their non-conductive properties, along with their lightweight and easy installation, make them highly suitable for electrical applications. In the realm of telecommunications, FRP pultrusion profiles are utilized for cable management systems, antenna supports, and equipment enclosures. Similar to their electrical applications, the non-conductive nature of these profiles ensures the safety and reliability of the telecommunications infrastructure. Additionally, these profiles can be tailored to meet specific design requirements, such as incorporating cable routing channels or equipment mounting brackets. Furthermore, FRP pultrusion profiles exhibit exceptional resistance to harsh environmental conditions, such as moisture, UV radiation, and chemicals. This makes them an excellent choice for outdoor electrical or telecommunications installations, where exposure to these elements is commonplace. All in all, FRP pultrusion profiles have proven themselves to be a dependable and cost-effective option for electrical and telecommunications applications. They provide insulation, strength, durability, and resistance to environmental factors, making them highly sought-after in these industries.

- Q: Are FRP pultrusion profiles resistant to caustic solutions?

- Yes, FRP pultrusion profiles are generally highly resistant to caustic solutions. The inherent chemical resistance of fiberglass-reinforced plastic (FRP) combined with the corrosion-resistant properties of the pultrusion manufacturing process make FRP pultrusion profiles an excellent choice for applications involving caustic solutions.

- Q: Are FRP pultrusion profiles resistant to electrical surges or lightning strikes?

- FRP pultrusion profiles are inherently non-conductive materials, which means they do not conduct electricity. Therefore, they can provide some level of resistance to electrical surges or lightning strikes. However, it is important to note that the level of resistance may vary depending on the specific composition and thickness of the FRP profiles. In high-risk areas prone to lightning strikes, additional measures may be necessary to ensure proper protection against electrical surges.

- Q: What are the features of Glass Fiber Reinforced Plastic Pultruded materials and chairs?

- Glass fiber reinforced plastic extruded sections for chair bars, corrosion resistance, aging resistance, good decorative (wood grain glass fiber reinforced plastic), Candice's color wood grain felt.No recycling value. I'd say that's probably the best feature right now. Installed, no one cares about, will not lose!

- Q: Are FRP pultrusion profiles resistant to hydraulic oils?

- Yes, FRP pultrusion profiles are generally resistant to hydraulic oils. The combination of fiberglass reinforcement and resin matrix used in pultrusion manufacturing makes these profiles highly resistant to various chemicals, including hydraulic oils. However, it is recommended to consult the specific resin manufacturer or supplier for detailed information on the compatibility of their FRP pultrusion profiles with different types of hydraulic oils.

Send your message to us

FRP Pultrusion Profiles Molded Gratings - Fiberglass & Plastic Grating Flooring

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords