FRP Pultrusion Profiles:FRP Rods and FRP Tubes Made in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 0 mm

- Supply Capability:

- 20000 mm/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description of FRP Rods and Tubes

FRP rods and tubes are manufantured by high-strength fiberglass as reinforcing material. thermosetting resin as the base, and then taken shape on a special pultruded mold, where the high temperature activates the resin to cure.

Main Features of FRP Rods and Tubes

light weight and high strength, anti-ageing, aesthetically pleasing appearance, environmental friendliness

Specifications of FRP Rods and Tubes

| Normal size | Φ32*Φ26,Φ32*Φ27.5,Φ32*Φ28,Φ32*Φ22,Φ31*Φ25,Φ30*Φ26,Φ30*Φ24,Φ28*Φ24,Φ28*Φ22,Φ25,.4*Φ20.5,Φ25.4*Φ18.4,Φ24*Φ20,Φ22*Φ18.4 |

| Surface effect | nexus mat surface, continuous strand mat surface, stitched mat surface, painting surface, wood texture surface |

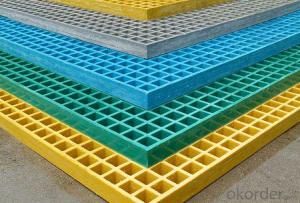

| Regular Color | yellow, red, blue, green, white, gary |

Applications of FRP Rods and Tubes

1.farming tool, shovel, hoe, pickaxe, ax, hammer etc.

2.gardening tool, grass shears, tree pruner, fencing shears, grass harrow etc.

3.cleaning tool, mop, broom, window brush etc.

IMages of FRP Rods and Tubes

FAQ

1. How about the documents after shipment?

After shipment, we ll send all original documents to you by DHL, including Packing List.Commercial Invoice, B/L, and other certificates as required by clients.

2. How long is the delivery time?

Usually it takes 10-25days after receipt of the deposits or L/C, and it also depends on the quantity of your order.

3. How's the payment?

Telegraphic Transfer(T/T) or Letter of Credit(L/C)

4. Do You Arrange Shipment?

Yes, dear esteemed customers, for FOB or CIF price, we will arrange shipment for you. For EXW price, clients need to arrange shipment by themselves or their agents.

5. How is the package?

Usually, we arrange the standard out-package for exporting.

- Q: Are FRP pultrusion profiles resistant to moisture or humidity?

- FRP pultrusion profiles boast exceptional resistance to moisture and humidity. Through the pultrusion process, continuous fibers are thoroughly saturated with a polymer resin, resulting in a steadfast and enduring composite material. This composite possesses inherent moisture resistance, differing from conventional materials like wood or metal, as it does not absorb water. Moreover, FRP pultrusion profiles exhibit a minimal coefficient of thermal expansion, minimizing the likelihood of expansion or contraction in response to varying humidity levels. This moisture and humidity resistance render FRP pultrusion profiles suitable for a diverse array of applications, including outdoor structures, marine environments, and other areas prone to moisture.

- Q: Can FRP pultrusion profiles be used in the construction of railway sleepers?

- Yes, FRP pultrusion profiles can be used in the construction of railway sleepers. FRP (Fiber Reinforced Polymer) offers high strength, durability, and corrosion resistance, making it a suitable material for railway applications. The pultrusion process ensures consistent quality and allows for the customization of profiles to meet specific requirements. Additionally, FRP pultrusion profiles are lightweight and have excellent electrical insulation properties, making them an ideal choice for railway sleepers.

- Q: Will the FRP section crack for a long time?

- Under normal circumstances, glass fiber reinforced plastic profiles will not appear cracking phenomenon, if there is cracking phenomenon, may be the following reasons:1, the placement method is incorrect, such as irregular, non closed section of a large number of stacked2 、 the resin content in the profile is low, filling is more (see if the section color is whiter, and more powder fall off at the same time)

- Q: Can FRP pultrusion profiles be used in high-voltage applications?

- Yes, FRP pultrusion profiles can be used in high-voltage applications. FRP (Fiber Reinforced Polymer) is a highly durable and electrically insulating material, making it suitable for use in high-voltage environments. The pultrusion process used to manufacture FRP profiles ensures that the material has a consistent and uniform composition, resulting in excellent electrical insulation properties. FRP pultrusion profiles have a high dielectric strength, meaning they can withstand high voltages without electrical breakdown. They also exhibit low electrical conductivity, preventing the flow of electric current through the material. This makes FRP profiles an ideal choice for applications where electrical insulation is crucial, such as high-voltage power transmission and distribution systems, electrical substations, and electrical equipment insulation. In addition to their electrical insulation properties, FRP pultrusion profiles offer several other advantages in high-voltage applications. They are lightweight, corrosion resistant, and have a high strength-to-weight ratio, making them easy to handle, install, and maintain. FRP profiles are also non-magnetic and non-conductive, reducing the risk of electromagnetic interference (EMI) in sensitive electrical systems. Overall, FRP pultrusion profiles are a reliable and efficient choice for high-voltage applications, providing excellent electrical insulation, durability, and performance in challenging environments.

- Q: What are the quality control measures for FRP pultrusion profiles?

- The quality control measures for FRP pultrusion profiles typically include visual inspection, dimensional checks, mechanical testing, and material analysis. Visual inspection ensures that the profiles are free from any visual defects such as cracks, voids, or surface imperfections. Dimensional checks verify that the profiles meet the required specifications and tolerances. Mechanical testing involves conducting various tests like flexural, tensile, and impact testing to ensure the profiles meet the required strength and performance criteria. Material analysis examines the composition and properties of the raw materials used in the pultrusion process to ensure they meet the desired standards. Overall, these quality control measures help ensure the consistent and reliable performance of FRP pultrusion profiles.

- Q: Can FRP pultrusion profiles be used in the construction of railway platforms?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in the construction of railway platforms. FRP pultruded profiles offer several advantages that make them suitable for this application. Firstly, FRP pultrusion profiles are lightweight yet highly durable. This makes them ideal for railway platforms as they can withstand heavy loads and frequent foot traffic without experiencing significant deformation or degradation over time. Secondly, FRP pultruded profiles have excellent corrosion resistance. This is particularly important for railway platforms, which are often exposed to harsh environmental conditions, including rain, snow, and salt. Unlike traditional materials such as steel or wood, FRP does not rust or rot, ensuring a longer lifespan for the platform. Additionally, FRP pultrusion profiles offer design flexibility. They can be customized to meet specific dimensional and structural requirements, allowing for the creation of platforms of various shapes and sizes. This versatility is beneficial for railway platforms, as they often need to be tailored to fit the available space and accommodate specific railway configurations. Furthermore, FRP pultrusion profiles have good electrical insulation properties. This is important for railway platforms, as they need to be electrically isolated from the tracks to prevent electrical shocks and ensure passenger safety. Lastly, FRP pultrusion profiles are easy to install and require minimal maintenance. They can be prefabricated off-site and quickly assembled on-site, reducing construction time and costs. Moreover, FRP does not require regular painting or sealing, saving both time and money on maintenance. In conclusion, FRP pultrusion profiles are a viable option for the construction of railway platforms due to their lightweight, durability, corrosion resistance, design flexibility, electrical insulation properties, and ease of installation and maintenance.

- Q: Can FRP pultrusion profiles be used in oil and gas applications?

- FRP pultrusion profiles are applicable for oil and gas purposes. These profiles possess exceptional resistance against corrosion, a high strength-to-weight ratio, and durability, making them suitable for a range of industries, including oil and gas. In oil and gas applications, FRP pultrusion profiles can serve multiple functions. They find use in constructing pipelines, offshore platforms, and subsea structures. They can also be utilized for fabricating tanks, vessels, and other equipment that are exposed to corrosive environments. A key advantage of FRP pultrusion profiles in oil and gas applications is their resistance to corrosion. Unlike traditional materials like steel, FRP does not rust or corrode when exposed to moisture, chemicals, or saltwater. This resistance extends the lifespan of the profiles and reduces maintenance costs. Furthermore, FRP pultrusion profiles offer high strength and stiffness. They can withstand high pressures, extreme temperatures, and harsh operating conditions commonly encountered in oil and gas environments. Their lightweight nature also facilitates easier handling and installation, especially when compared to heavier materials such as steel. Another benefit of FRP profiles is their non-conductive property. This characteristic makes them suitable for applications where electrical conductivity should be minimized, such as offshore platforms or areas with potential electrical hazards. In conclusion, FRP pultrusion profiles are a reliable and cost-effective solution for oil and gas applications. Their corrosion resistance, high strength, and lightweight properties make them ideal for various components and structures within the industry.

- Q: How do FRP pultrusion profiles compare to traditional building materials?

- FRP pultrusion profiles offer numerous advantages over traditional building materials. They are lightweight yet incredibly strong, providing high structural integrity. These profiles are resistant to corrosion, chemicals, and UV radiation, ensuring long-term durability. Additionally, FRP pultrusion profiles have excellent insulation properties, making them ideal for various applications. They are also easy to install, require minimal maintenance, and are cost-effective in the long run. Overall, FRP pultrusion profiles outperform traditional building materials in terms of strength, durability, versatility, and efficiency.

- Q: Can FRP pultrusion profiles be used in the construction industry?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in the construction industry. FRP pultruded profiles offer several advantages that make them suitable for various construction applications. Firstly, FRP pultrusion profiles are lightweight yet exceptionally strong. This makes them an excellent choice for construction projects as they provide high strength-to-weight ratio, reducing the overall weight of the structure while maintaining structural integrity. This can be particularly advantageous in applications such as bridges, walkways, and platforms. Secondly, FRP pultrusion profiles are highly corrosion resistant. Unlike traditional construction materials like steel or wood, FRP does not rust, rot, or corrode when exposed to harsh environmental conditions, chemicals, or moisture. This makes FRP profiles ideal for outdoor or marine applications where corrosion is a concern, such as seawalls, docks, or offshore structures. Additionally, FRP pultrusion profiles have excellent electrical and thermal insulation properties. This makes them suitable for applications where electrical conductivity needs to be minimized, such as electrical enclosures or cable trays. FRP profiles also have low thermal conductivity, which can help improve energy efficiency in buildings by reducing heat transfer. Furthermore, FRP pultrusion profiles are highly durable and require minimal maintenance. They have a long service life and do not require regular painting, sealing, or treatment like traditional materials. This can result in significant cost savings over the life cycle of a construction project. Lastly, FRP pultrusion profiles can be designed to meet specific strength, stiffness, and dimensional requirements. They can be manufactured in various shapes, sizes, and colors, allowing for flexibility in design and customization. This versatility makes FRP profiles suitable for a wide range of construction applications, including beams, columns, gratings, handrails, and structural components. In summary, FRP pultrusion profiles are a viable option for the construction industry due to their lightweight, high strength, corrosion resistance, electrical and thermal insulation properties, durability, low maintenance requirements, and design flexibility.

- Q: Can FRP pultrusion profiles be used in the aerospace and aviation industry?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in the aerospace and aviation industry. FRP pultrusion profiles offer exceptional strength-to-weight ratio, corrosion resistance, and design flexibility, making them suitable for various applications in this industry. One of the key advantages of FRP pultrusion profiles is their high strength-to-weight ratio. This means that they can provide the required structural integrity while keeping the weight of the components low, which is crucial in aerospace and aviation applications where weight reduction is a priority. The lightweight nature of FRP profiles can contribute to fuel efficiency, improved performance, and increased payload capacity. Additionally, FRP pultrusion profiles exhibit excellent resistance to corrosion, including resistance to chemicals, moisture, and UV radiation. This makes them highly suitable for use in aircraft and aerospace systems, where exposure to harsh environmental conditions is common. Unlike traditional metallic materials, FRP profiles can withstand corrosive agents and maintain their structural integrity for extended periods, reducing maintenance requirements and enhancing the durability of aircraft components. Furthermore, the design flexibility of FRP pultrusion profiles allows for the creation of complex shapes and geometries, enabling engineers to tailor the profiles to meet specific requirements. This versatility in design opens up opportunities for innovative solutions in aerospace and aviation applications, such as structural components, aircraft interiors, radomes, fairings, and more. It is worth mentioning that FRP pultrusion profiles have been successfully used in the aerospace and aviation industry for various applications, including wing spars, stabilizers, galleys, interior panels, and cargo containers. Their proven track record demonstrates their reliability and performance in demanding environments. Overall, FRP pultrusion profiles are well-suited for use in the aerospace and aviation industry due to their high strength-to-weight ratio, corrosion resistance, and design flexibility. Their use can contribute to lighter, more efficient, and durable aircraft components, making them a viable choice for various applications in this sector.

Send your message to us

FRP Pultrusion Profiles:FRP Rods and FRP Tubes Made in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 0 mm

- Supply Capability:

- 20000 mm/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords