FRP Pultrusion Profiles - Fiberglass FRP Phenolic Molded & Pultruded Gratings

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction

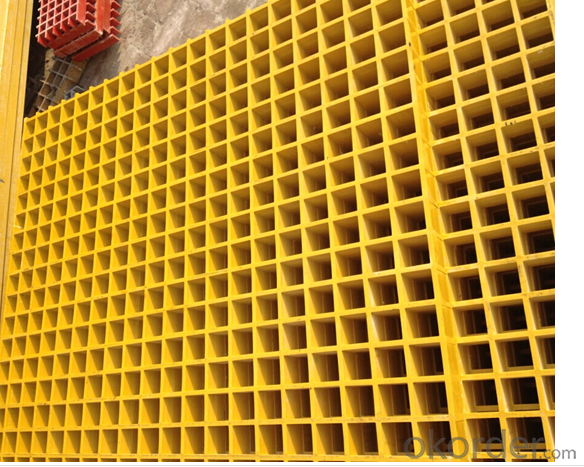

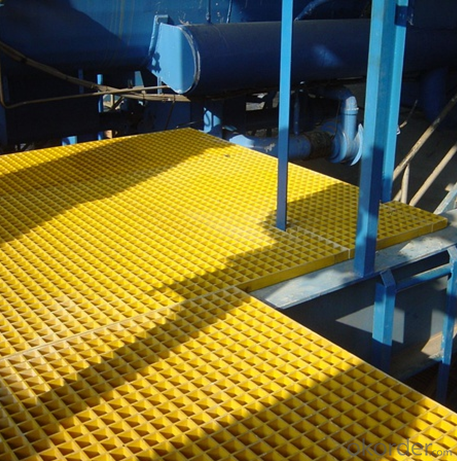

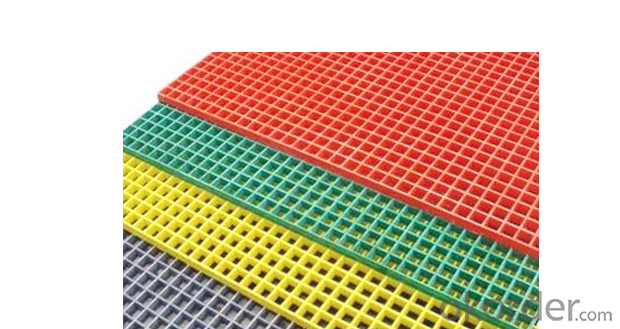

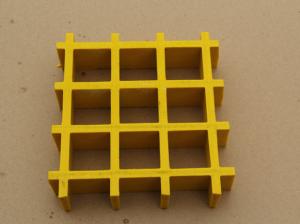

FRP Molded Grating is a structural panel which uses high-strength E-Glass roving as reinforcing material, thermosetting resin as matrix and then casted and formed in a special metal mold. It provides properties of light weight, high strength, corrosion resistance, fire resistance and anti-skid. FRP Molded Grating is widely used in oil industry, power engineering, water & waste water treatment, ocean survey as working floor, stair tread, trench cover, etc. and is an ideal loading frame for corrosion circumstances.

Feature

l Corrosion Resistance

l Safety & Anti-slip

l Electrical Insulating

l Aging Resistance

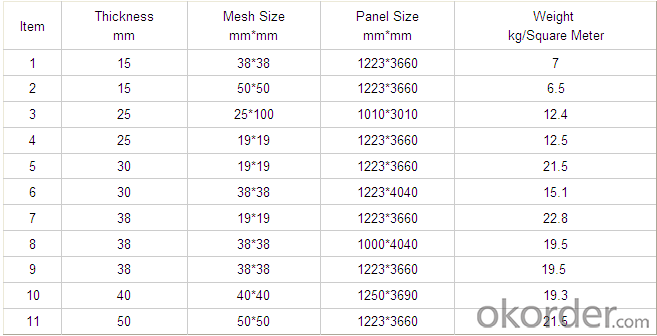

Specification

Advantage

1) coated with prevent aging layer

2) high strength

3) long service life

4) easy installation

Application

l Power plants, substation equipment enclosures, antimagnetic, anti-static,to prevent small animals into the equipment failure, as there is electricity facilities and without power interval intervals.

l Corrosive chemical industry equipment around the fence

l All kinds of building maintenance section

FAQ

1. How's the payment?

Telegraphic Transfer(T/T) or Letter of Credit(L/C)

2. Do You Arrange Shipment?

Yes, dear esteemed customers, for FOB or CIF price, we will arrange shipment for you. For EXW price, clients need to arrange shipment by themselves or their agents.

3. How is the package?

Usually, we arrange the standard out-package for exporting.

PROCESS

FACTORY

- Q: Are FRP pultrusion profiles resistant to hydrocarbons?

- FRP pultrusion profiles are known to be resistant against hydrocarbons. By combining different reinforcing fibers, such as fiberglass or carbon fiber, with a polymer matrix, FRP materials exhibit a high level of resistance to chemical corrosion, including hydrocarbons. This resistance makes FRP pultrusion profiles an excellent choice for applications that involve exposure to hydrocarbons, such as in the oil and gas industry, chemical processing plants, and fuel storage facilities. However, it is important to bear in mind that the level of resistance may vary depending on the specific resin used in the FRP material, as well as the concentration and temperature of the hydrocarbons present. Hence, it is advisable to consult with the manufacturer or supplier of the FRP pultrusion profiles to confirm their compatibility with the particular hydrocarbon environment at hand.

- Q: Are FRP pultrusion profiles resistant to seismic activity?

- Yes, FRP pultrusion profiles are generally resistant to seismic activity. Due to their high strength-to-weight ratio and excellent flexibility, FRP profiles have demonstrated great resilience and durability during seismic events. Additionally, their non-corrosive nature and superior fatigue resistance make them suitable for seismic-prone regions. However, specific design considerations and engineering analysis are necessary to ensure optimal performance in seismic conditions.

- Q: Do you have any high temperature resistant resin made of pultruded glass fiber reinforced plastic?

- Unsaturated polyester resin can not meet the high temperature requirements, epoxy resin also needs to be synthesized

- Q: How do FRP pultrusion profiles perform in extreme temperatures?

- FRP pultrusion profiles generally perform well in extreme temperatures due to their inherent thermal stability and resistance to temperature variations. The material's composition, typically made of reinforced fibers and polymer resin, allows it to maintain its structural integrity and mechanical properties across a wide range of temperatures. This makes FRP pultrusion profiles suitable for use in both extremely hot and extremely cold environments, as they are less prone to expansion, contraction, or degradation compared to other materials.

- Q: How do FRP pultrusion profiles perform in coastal environments?

- FRP pultrusion profiles are highly durable and perform exceptionally well in coastal environments. The combination of fiberglass reinforcement and resin matrix makes them resistant to corrosion, moisture, and UV radiation, which are prevalent in coastal areas. These profiles have excellent resistance to saltwater, chemicals, and other harsh elements commonly found in coastal environments. Due to their corrosion resistance, FRP pultrusion profiles do not rust or degrade over time, unlike traditional materials such as steel or wood. This durability ensures their long-lasting performance and reduces the need for frequent maintenance or replacement. Furthermore, FRP pultrusion profiles have a high strength-to-weight ratio, making them an ideal choice for coastal applications. They are lightweight yet robust, providing structural stability and reliability in harsh coastal conditions. Their non-conductive nature also eliminates the risk of electrical conductivity, which is crucial in coastal areas where saltwater and humidity can cause electrical corrosion. Another advantage of FRP pultrusion profiles in coastal environments is their ability to withstand extreme temperature variations. They can withstand both hot and cold climates without losing their structural integrity or dimensional stability. This makes them suitable for coastal regions with varying weather conditions. In summary, FRP pultrusion profiles excel in coastal environments due to their corrosion resistance, durability, lightweight nature, and ability to withstand extreme weather conditions. Their performance and longevity make them a reliable choice for various applications such as marine structures, coastal infrastructure, and offshore installations.

- Q: What is the impact resistance of FRP pultrusion profiles?

- The impact resistance of FRP (Fiber Reinforced Polymer) pultrusion profiles is generally quite high. FRP pultrusion profiles are made by pulling reinforcing fibers, such as fiberglass, through a resin bath and then into a heated die, where the resin cures and solidifies. This manufacturing process creates a strong and durable composite material with excellent mechanical properties, including impact resistance. The specific impact resistance of FRP pultrusion profiles can vary depending on the specific formulation and design of the profile, as well as the type and orientation of the reinforcing fibers used. However, in general, FRP pultrusion profiles have been found to have superior impact resistance compared to traditional materials like steel or aluminum. The combination of the reinforcing fibers and the resin matrix in FRP pultrusion profiles provides enhanced strength and toughness, which allows the profiles to withstand high impact loads without cracking, breaking, or deforming. This makes FRP pultrusion profiles suitable for a wide range of applications where impact resistance is critical, such as in construction, transportation, and sporting goods. Furthermore, FRP pultrusion profiles can be designed to have varying levels of impact resistance by adjusting the fiber content, fiber orientation, resin type, and other factors during the manufacturing process. This allows for customization of the profiles based on specific application requirements. In conclusion, FRP pultrusion profiles offer excellent impact resistance due to the combination of reinforcing fibers and resin matrix. Their high strength, toughness, and ability to withstand impact loads make them a reliable choice for various industries and applications.

- Q: Are FRP pultrusion profiles resistant to impact from flying debris?

- FRP pultrusion profiles possess notable strength and durability, earning them a reputation in the industry. Their inherent properties make them generally impervious to damage caused by flying debris. This exceptional impact resistance can be attributed to the combination of reinforcing fibers, often fiberglass, and the polymer matrix. The extent of resistance to flying debris impact may vary depending on the design, thickness, and composition of the FRP pultrusion profiles. Nevertheless, these profiles are typically engineered to withstand impact forces and effectively withstand damage from airborne debris. Moreover, FRP pultrusion profiles find extensive use in industries such as construction, transportation, and infrastructure, where impact resistance is of utmost importance. These profiles have undergone rigorous testing and have demonstrated their ability to endure various impact scenarios, making them a trustworthy choice for applications that involve the potential for flying debris. It is vital to recognize that although FRP pultrusion profiles boast commendable impact resistance, the severity of the impact and the speed of the flying debris can still impact the degree of damage incurred. Thus, it is advisable to consult with the manufacturer or an engineer to ensure the chosen FRP profile is suitable for the intended application and potential impact conditions.

- Q: Are FRP pultrusion profiles resistant to oil and grease?

- FRP (Fiber Reinforced Plastic) pultrusion profiles are generally known for their excellent resistance to oil and grease. The combination of fibers, typically glass or carbon, with a polymer resin matrix results in a material that is inherently resistant to many chemicals, including oil and grease. This resistance is attributed to the non-reactive nature of the polymer resin, which prevents the oil or grease from penetrating the material and causing damage. Additionally, the pultrusion manufacturing process used to produce FRP profiles further enhances their resistance to oil and grease. During the pultrusion process, the fibers are impregnated with the resin and then pulled through a heated die, where the resin is cured. This creates a strong, uniform material with a dense surface that is less porous and more resistant to chemical penetration. It is important to note that the specific resistance of FRP pultrusion profiles to oil and grease can vary depending on the type of resin used and the specific application conditions. In some cases, specialized resin formulations can be used to further enhance the oil and grease resistance of FRP profiles, ensuring suitability for even more demanding environments. Overall, FRP pultrusion profiles are generally considered to be highly resistant to oil and grease, making them an excellent choice for applications where exposure to these substances is expected. However, it is always recommended to consult with the manufacturer or supplier to ensure that the specific FRP profile being used is appropriate for the intended application and chemical exposure.

- Q: Can FRP pultrusion profiles be used in the construction and building materials industry?

- FRP pultrusion profiles are indeed applicable in the construction and building materials sector. These profiles are created by pulling continuous fibers through a resin bath and then into a heated die, which aids in curing the resin and shaping the profile. One of the primary advantages of FRP pultrusion profiles lies in their exceptional strength-to-weight ratio. Despite being lightweight, they possess incredible durability and strength, making them an optimal choice for construction purposes where weight reduction is desired. Moreover, FRP pultrusion profiles exhibit outstanding resistance to corrosion, which proves particularly advantageous in environments with moisture, chemicals, or harsh weather conditions. This corrosion resistance extends the lifespan of building materials, thereby reducing maintenance and replacement expenses. FRP pultrusion profiles can serve a wide array of construction applications, including structural components like beams, columns, and trusses. They are also frequently utilized as reinforcements in concrete structures, offering added strength and durability. Additionally, these profiles find utility in cladding, decking, handrails, ladders, and other non-structural elements within buildings. Furthermore, FRP pultrusion profiles provide design flexibility as they can easily be customized and manufactured to specific shapes, sizes, and properties. This adaptability renders them suitable for diverse construction projects, ranging from small-scale residential buildings to large-scale industrial complexes. In conclusion, FRP pultrusion profiles are highly appropriate for the construction and building materials industry due to their superior strength-to-weight ratio, corrosion resistance, design flexibility, and versatility.

- Q: Is the test standard for FRP pultruded profiles and FRP gratings the same?

- Different process, production, different uses, testing standards, of course, there are differences.

Send your message to us

FRP Pultrusion Profiles - Fiberglass FRP Phenolic Molded & Pultruded Gratings

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords