FRP Pultrusion Profiles - Fiberglass FRP Phenolic Molded and Pultruded Gratings in All Kinds of Colors

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction

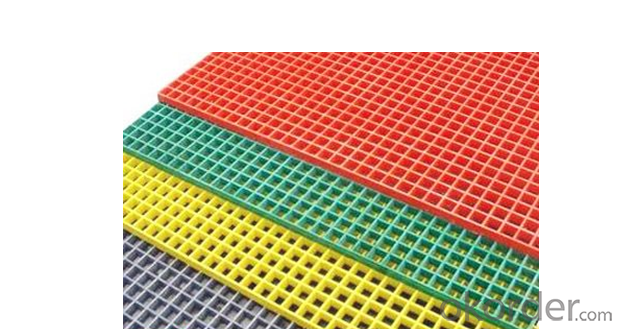

FRP Molded Grating is a structural panel which uses high-strength E-Glass roving as reinforcing material, thermosetting resin as matrix and then casted and formed in a special metal mold. It provides properties of light weight, high strength, corrosion resistance, fire resistance and anti-skid. FRP Molded Grating is widely used in oil industry, power engineering, water & waste water treatment, ocean survey as working floor, stair tread, trench cover, etc. and is an ideal loading frame for corrosion circumstances.

Feature

Corrosion Resistance

- Safety & Anti-slip

Electrical Insulating

Aging Resistance

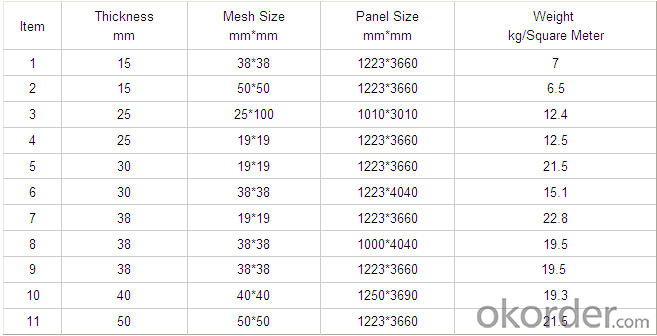

Specification

Advantage

coated with prevent aging layer

- long service life

easy installation

Application

Power plants, substation equipment enclosures, antimagnetic, anti-static,to prevent small animals into the equipment failure, as there is electricity facilities and without power interval intervals.

- Corrosive chemical industry equipment around the fence

All kinds of building maintenance section

FAQ

1. How about the documents after shipment?

After shipment, we ll send all original documents to you by DHL, including Packing List.Commercial Invoice, B/L, and other certificates as required by clients.

2. How long is the delivery time?

Usually it takes 10-25days after receipt of the deposits or L/C, and it also depends on the quantity of your order.

3. How is the package?

Usually, we arrange the standard out-package for exporting.

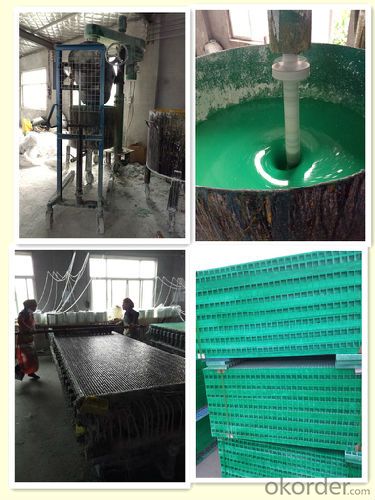

PROCESS

FACTORY

- Q: How do FRP pultrusion profiles perform in high-vibration applications?

- High-vibration applications are where FRP (Fiber Reinforced Polymer) pultrusion profiles truly excel. The exceptional properties of FRP materials make them an ideal choice for these situations. To begin with, FRP pultrusion profiles are renowned for their impressive strength-to-weight ratio. Unlike traditional materials like steel or aluminum, FRP profiles are significantly lighter while still possessing remarkable strength and rigidity. This lightweight quality reduces the overall mass of the structure, resulting in lower vibration amplitudes. Furthermore, FRP materials boast outstanding damping characteristics. Damping refers to a material's ability to dissipate energy and decrease vibration amplitudes. In comparison to other materials, FRP pultrusion profiles have a higher damping coefficient, meaning they can more effectively absorb and dissipate vibrations. This minimizes the transmission of vibrations throughout the structure, reducing the risk of resonance and fatigue failure. In addition, FRP pultrusion profiles demonstrate exceptional resistance to fatigue and corrosion. Vibrations can cause cyclic loading, which can lead to fatigue failure over time. However, the inherent properties of FRP materials, including their excellent tensile strength and resistance to environmental factors, make them highly resilient to fatigue and corrosion. This guarantees the longevity and durability of the profiles, even in high-vibration environments. Moreover, FRP pultrusion profiles offer immense design flexibility, allowing for customized shapes and sizes that can be tailored to specific applications. This flexibility allows engineers to optimize the profiles' performance in high-vibration scenarios by adjusting the geometry and composition to enhance their dynamic characteristics. In summary, FRP pultrusion profiles are exceptionally suited for high-vibration applications due to their lightweight nature, excellent damping characteristics, resistance to fatigue and corrosion, and design flexibility. These profiles provide a reliable and durable solution that can effectively withstand the challenges posed by vibrations, ensuring safe and efficient operation in such environments.

- Q: Can FRP pultrusion profiles be used in the construction of wastewater treatment tanks?

- Indeed, wastewater treatment tanks can effectively utilize FRP pultrusion profiles. These profiles are renowned for their exceptional strength-to-weight ratio, resistance to corrosion, and longevity, making them an optimal option for harsh environments such as wastewater treatment facilities. To manufacture FRP pultrusion profiles, continuous fibers like glass or carbon are drawn through a resin bath and subsequently through a heated die to attain the desired shape. This process yields profiles with consistent cross-sections and outstanding mechanical properties. In the construction of wastewater treatment tanks, FRP pultrusion profiles can serve various purposes. They can function as structural components, like beams, columns, and bracing systems, offering the necessary strength and rigidity to support the tank structure. Additionally, FRP profiles can reinforce concrete structures, bolstering their durability and resistance against chemical attack from the wastewater. Moreover, FRP pultrusion profiles can be engineered to endure the corrosive impact of the chemicals and gases found in wastewater treatment tanks. Unlike conventional materials such as steel or concrete, FRP exhibits a high resistance to corrosion, guaranteeing an extended service life and reduced maintenance expenses. Furthermore, FRP profiles provide advantages in terms of installation and transportation. They are lightweight, enabling easier handling and diminished labor requirements during construction. The modular nature of FRP profiles also facilitates swift assembly and disassembly, simplifying maintenance and modifications. Overall, incorporating FRP pultrusion profiles in the construction of wastewater treatment tanks offers numerous benefits, including superior strength, corrosion resistance, durability, and ease of installation. These advantages render FRP a dependable and cost-effective choice for wastewater treatment facilities.

- Q: Can FRP pultrusion profiles be used in the construction of amusement park rides?

- Yes, FRP pultrusion profiles can be used in the construction of amusement park rides. FRP (Fiber Reinforced Polymer) pultrusion profiles offer high strength-to-weight ratio, corrosion resistance, and durability, making them suitable for various applications in amusement park rides. These profiles can be used for structural components, such as supports, frames, and beams, as well as for aesthetic elements like facades or decorative structures. Additionally, FRP pultrusion profiles can be customized to meet specific design requirements, making them a versatile choice for constructing amusement park rides.

- Q: Can FRP pultrusion profiles be used in the construction of swimming pool enclosures?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in the construction of swimming pool enclosures. FRP pultrusion profiles are known for their high strength-to-weight ratio, corrosion resistance, and durability, making them suitable for outdoor applications like swimming pool enclosures. They are lightweight, easy to install, and have excellent resistance to water, chemicals, and UV radiation, making them an ideal choice for constructing enclosures that can withstand the harsh pool environment. Additionally, FRP pultrusion profiles offer design flexibility, allowing for the creation of various shapes and sizes to meet specific enclosure requirements.

- Q: Are FRP pultrusion profiles resistant to alkalis?

- Yes, FRP pultrusion profiles are generally resistant to alkalis.

- Q: Are FRP pultrusion profiles resistant to chemicals used in food packaging?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles are generally resistant to chemicals used in food packaging. FRP materials are known for their excellent resistance to a wide range of chemicals, including those commonly used in food packaging such as acids, bases, solvents, and oils. This chemical resistance makes FRP pultrusion profiles a suitable choice for applications involving contact with food packaging materials. However, it is important to note that the specific resistance of FRP profiles may vary depending on the formulation and type of resin used. Therefore, it is advisable to consult with the manufacturer or supplier to ensure that the chosen FRP pultrusion profiles are suitable for the specific chemicals used in the food packaging industry.

- Q: Can FRP pultrusion profiles be used in the construction of industrial flooring?

- Yes, FRP pultrusion profiles can be used in the construction of industrial flooring. These profiles are lightweight, durable, and corrosion-resistant, making them an ideal choice for industrial applications. They offer high strength-to-weight ratio, excellent load-bearing capacity, and resistance to chemicals, moisture, and extreme temperatures. Additionally, FRP pultrusions can be customized to meet specific design requirements, making them versatile for various industrial flooring applications.

- Q: Can FRP pultrusion profiles be used in aerospace applications?

- FRP pultrusion profiles are applicable in aerospace applications. They possess numerous advantages that render them suitable for use in this field. Firstly, their exceptional strength-to-weight ratios are crucial in the aerospace industry as they contribute to weight reduction and fuel efficiency improvement. Secondly, FRP materials display high resistance to corrosion, making them suitable for enduring exposure to harsh environments like high altitudes and extreme temperatures. Additionally, FRP pultrusion profiles provide design flexibility, allowing for the production of intricate shapes and geometries. This flexibility enables aerospace engineers to customize the profiles according to specific requirements and optimize their performance. Moreover, FRP materials exhibit low thermal conductivity, which aids in insulation applications and minimizes heat transfer. Lastly, FRP pultrusion profiles have demonstrated commendable fatigue resistance, a crucial factor for aerospace applications subjected to cyclic loading. Overall, these properties establish FRP pultrusion profiles as a viable option for various aerospace components, including structural members, interior parts, and electrical enclosures.

- Q: Plastic or better glass fiber reinforced plastic better?

- Glass fiber reinforced plastics, usually glass fiber reinforced unsaturated polyester, epoxy resin and phenolic resin matrix. Because of the different kinds of resins used, they are called polyester glass fiber reinforced plastics, epoxy glass fiber reinforced plastics and phenolic resin glass fiber reinforced plastics. Its characteristics are: light and hard, non conductive, stable performance, high mechanical strength, less recycling and corrosion resistance. It can be used instead of steel to make machine parts, automobiles, ship shells, etc..

- Q: Are FRP pultrusion profiles resistant to impact?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles are generally resistant to impact. The combination of the high-strength fibers and the polymer matrix used in the manufacturing process makes FRP profiles highly durable and able to withstand significant impacts without cracking or breaking. Additionally, the pultrusion process ensures that the fibers are uniformly distributed throughout the profile, further enhancing its impact resistance. This makes FRP pultrusion profiles ideal for applications where impact resistance is important, such as in construction, transportation, and infrastructure projects.

Send your message to us

FRP Pultrusion Profiles - Fiberglass FRP Phenolic Molded and Pultruded Gratings in All Kinds of Colors

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords