FRP Pultrusion Profiles - Pultruded Grating Walkway Floor & Pultruded Platform

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m

- Supply Capability:

- 80000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

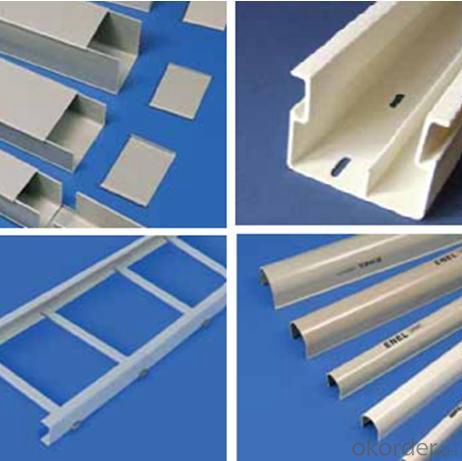

PRODUCT DESCRIPTION

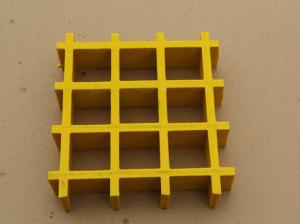

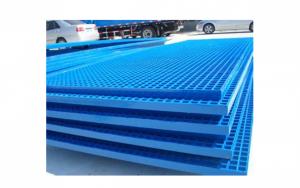

Pultruded grating is made by a particular assembly process, which using “I” shape as its main load-bearing and special rod to go through the bearing bar. Pultruded grating include the standard grating and the custom grating, the custom grating can be designed to meet customer’s requirement or special using condition by changing the shape, size and space of the bearing bars, the surface can be covered with lozenge panel, grit panel, or added the anti-slippery sand directly.

FRP pultruded grating has the most characteristics of molded grating, but it has its distinct advantages, it has very high fiberglass content in the loading direction, so it has very high load capability, it has more superiority when used at wide span, so that the basic support will be decreased and the project cost will be reduced accordingly.

FEATURES

1.Electrically and thermally non-conductive

2.Ultra-violet resistant

3.Provided in a number of gratings thickness and panel sizes with many types of mesh size

4.Offers bi-directional strength characteristic

5.Impact resistance

6.insulationt

SPECIFICATIONS

Name | Ring Lock scaffolding |

Size | Ø48.3*3.25*1000/2000/3000 or as your request |

Main Material | Q195,Q235,Q345 |

Surface Treatment | HDG, dip painting, galvanize, Powder Coating |

Application | Slab support, working platform, construction, warehouse storage shelf, stage |

Color | Silver, Dark red or as request |

Certificate | SGS, EN12810.ISO |

Service | OEM Service available |

PICTURES

- Q: How do FRP pultrusion profiles perform in high-vibration applications?

- FRP (Fiber Reinforced Polymer) pultrusion profiles perform exceptionally well in high-vibration applications. The inherent properties of FRP materials make them ideal for such situations. Firstly, FRP pultrusion profiles are known for their high strength-to-weight ratio. This means that they are significantly lighter than traditional materials such as steel or aluminum, yet possess great strength and rigidity. This lightweight nature helps to reduce the overall mass of the structure, resulting in a lower vibration amplitude. Secondly, FRP materials have excellent damping characteristics. Damping refers to the ability of a material to dissipate energy and reduce vibration amplitudes. FRP pultrusion profiles have a higher damping coefficient compared to other materials, which means they can absorb and dissipate vibrations more effectively. This helps in minimizing the transmission of vibrations throughout the structure, reducing the potential for resonance and fatigue failure. Additionally, FRP pultrusion profiles exhibit a high resistance to fatigue and corrosion. Vibrations can induce cyclic loading, which can lead to fatigue failure over time. However, the inherent properties of FRP materials, such as their excellent tensile strength and resistance to environmental factors, make them highly resistant to fatigue and corrosion. This ensures the longevity and durability of the profiles even in high-vibration environments. Furthermore, FRP pultrusion profiles offer design flexibility, allowing for customized shapes and sizes that can be tailored to specific applications. This flexibility enables engineers to optimize the profiles' performance in high-vibration scenarios by adjusting the geometry and composition to enhance their dynamic characteristics. In summary, FRP pultrusion profiles are well-suited for high-vibration applications due to their lightweight nature, excellent damping characteristics, resistance to fatigue and corrosion, and design flexibility. These profiles provide a reliable and durable solution that can effectively withstand the challenges posed by vibrations, ensuring a safe and efficient operation in such environments.

- Q: Are FRP pultrusion profiles resistant to chemicals used in oil refineries?

- Yes, FRP pultrusion profiles are highly resistant to chemicals used in oil refineries. The combination of their fiberglass reinforcement and resin matrix makes them impervious to many corrosive substances, ensuring long-term durability and performance in such harsh environments.

- Q: What are the maintenance requirements for FRP pultrusion profiles?

- FRP pultrusion profiles have low maintenance requirements due to their durability and resistance to corrosion. They are a low-maintenance choice for various applications. However, there are a few important maintenance practices that can help prolong their lifespan and ensure optimal performance. Firstly, it is important to periodically clean the profiles to remove dirt, dust, and debris. This can be achieved by using a mild detergent solution and a soft brush or cloth. It is advisable to avoid abrasive cleaners or materials that could scratch the surface. Regular visual inspections should also be conducted to identify any signs of damage or wear. Cracks, chips, delamination, or any other visible defects should be promptly addressed to prevent further damage. While FRP pultrusion profiles are generally resistant to UV radiation, prolonged exposure to direct sunlight can cause some degradation. Applying a UV protective coating or using a UV-resistant paint can minimize the effects of UV exposure and extend the profiles' lifespan. For pultrusion profiles with moving parts or connections, such as hinges or joints, it is important to apply a suitable lubricant to ensure smooth operation and prevent friction-related issues. It is crucial to use lubricants compatible with FRP materials to avoid any adverse chemical reactions. In the event of significant damage or wear, it may be necessary to repair or replace the affected sections of the FRP pultrusion profiles. Trained professionals with experience working with FRP materials should perform this task to ensure proper repair techniques and maintain structural integrity. In conclusion, while FRP pultrusion profiles require minimal maintenance, regular cleaning, inspection, and prompt addressing of issues are crucial for their longevity and optimal performance. By following these maintenance practices, the lifespan of FRP pultrusion profiles can be maximized while maintaining their structural integrity over time.

- Q: Can FRP pultrusion profiles be used in the construction of train or subway platforms?

- Yes, FRP pultrusion profiles can be used in the construction of train or subway platforms. FRP (Fiber Reinforced Polymer) offers excellent strength, durability, and corrosion resistance, making it suitable for high-traffic areas like train or subway platforms. Additionally, FRP pultrusion profiles can be customized to meet specific design requirements, making them a versatile choice for platform construction.

- Q: Are FRP pultrusion profiles resistant to fading or discoloration?

- FRP pultrusion profiles possess exceptional resistance against fading and discoloration. This attribute stems from the inherent properties of the materials employed in their construction. Typically, FRP profiles are fabricated using a blend of fiberglass reinforcements and a polymer resin matrix, both of which inherently resist UV radiation and other environmental factors that lead to fading and discoloration. The polymer resin matrix used in FRP profiles is specifically designed to exhibit outstanding chemical resistance and UV stability. As a result, the profiles retain their original color and appearance for an extended duration. This makes FRP pultrusion profiles an ideal choice for outdoor applications, where exposure to sunlight and harsh weather conditions is prevalent. Additionally, the pultrusion manufacturing process ensures that the color of FRP profiles remains consistent throughout their entire cross-section. Consequently, even in the presence of minor surface damage or wear, the underlying color of the profile remains unchanged, ensuring a uniform appearance. In summary, FRP pultrusion profiles offer unparalleled resistance against fading and discoloration, making them a resilient and long-lasting option for a wide range of applications, including construction, infrastructure, transportation, and more.

- Q: Are FRP pultrusion profiles resistant to caustic solutions?

- FRP pultrusion profiles are known for their resistance to caustic solutions. The combination of reinforcing fibers and the polymer matrix used in FRP pultrusion provides exceptional chemical resistance. Unlike traditional materials like steel or wood, which can be corroded or degraded by strong alkaline substances, FRP pultrusion profiles are highly resistant to chemical attack. This makes them suitable for industries that frequently encounter caustic solutions, such as chemical processing, wastewater treatment, and marine environments. However, it is important to refer to the manufacturer's specifications and guidelines to ensure compatibility between specific caustic solutions and the chosen FRP pultrusion profile.

- Q: Will the FRP section crack for a long time?

- It will be。Glass steel cracking has the following factors:1, in production, the ingredients are too high, curing reaction is fierce.2, in production, the product is too thick, no sub operation, resulting in thermal cracking.3, the product stiffness is not enough, deformation is too large and cracks.4, the strength of the product is not enough, the use of excessive force due to cracks.5, surface gel will produce cracks due to thermal contraction.

- Q: What are the insulation properties of FRP pultrusion profiles?

- Due to the composition of the materials used, FRP pultrusion profiles possess exceptional insulation characteristics. FRP, an acronym for Fiber Reinforced Polymer, combines the reinforcing strength of fibers with the insulating attributes of the polymer matrix. The insulation qualities of FRP pultrusion profiles chiefly depend on the polymer matrix, which typically consists of thermosetting resins such as polyester, vinyl ester, or epoxy. These resins possess low thermal conductivity, meaning they have poor heat-conducting abilities. This property allows FRP pultrusion profiles to effectively minimize heat transfer via conduction. In addition to their low thermal conductivity, FRP pultrusion profiles also exhibit outstanding electrical insulation properties. The polymer matrix functions as an insulator, preventing the flow of electric current and minimizing the risk of electrical accidents or equipment damage. Moreover, FRP pultrusion profiles demonstrate resistance to moisture, chemicals, and UV radiation, further enhancing their insulation capabilities. Moisture and chemicals can compromise the insulation properties of materials, but FRP exhibits a high level of resistance to these factors, ensuring long-lasting insulation performance. In conclusion, FRP pultrusion profiles offer exceptional insulation properties, making them an ideal choice for applications that require thermal or electrical insulation. They provide a dependable and durable solution for various industries, including construction, electrical, and transportation.

- Q: Are FRP pultrusion profiles resistant to chemicals used in food packaging?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles are generally resistant to chemicals used in food packaging. FRP materials are known for their excellent resistance to a wide range of chemicals, including those commonly used in food packaging such as acids, bases, solvents, and oils. This chemical resistance makes FRP pultrusion profiles a suitable choice for applications involving contact with food packaging materials. However, it is important to note that the specific resistance of FRP profiles may vary depending on the formulation and type of resin used. Therefore, it is advisable to consult with the manufacturer or supplier to ensure that the chosen FRP pultrusion profiles are suitable for the specific chemicals used in the food packaging industry.

- Q: Are FRP pultrusion profiles fire resistant?

- FRP pultrusion profiles exhibit excellent fire resistance due to the combination of reinforcing fibers and the polymer matrix employed in their production. These profiles are crafted through the pultrusion process, wherein reinforcing fibers like fiberglass or carbon fiber are impregnated with a thermosetting resin. This resin undergoes a curing process, resulting in a robust and durable composite material. One of the primary advantages of FRP pultrusion profiles lies in their inherent fire resistance. The thermosetting resin utilized in their manufacture possesses properties that render it highly impervious to fire. When subjected to flames or elevated temperatures, the resin does not easily burn or melt, thereby impeding the propagation of fire. Moreover, the reinforcing fibers present in FRP profiles contribute significantly to their fire resistance. For example, fiberglass, being an inorganic substance, does not combust. It serves as a heat transfer barrier, aiding in the containment of flames. Additionally, FRP pultrusion profiles can be engineered to meet specific fire safety standards and regulations. By incorporating supplementary fire retardant additives or employing specialized resin systems, the fire resistance of these profiles can be further enhanced. It is crucial to note that although FRP pultrusion profiles do possess fire resistance, their precise fire rating may vary depending on the particular composition and design. Thus, it is imperative to consult manufacturers or suppliers who can furnish comprehensive information regarding the fire resistance properties of their FRP pultrusion profiles.

Send your message to us

FRP Pultrusion Profiles - Pultruded Grating Walkway Floor & Pultruded Platform

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m

- Supply Capability:

- 80000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords