All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

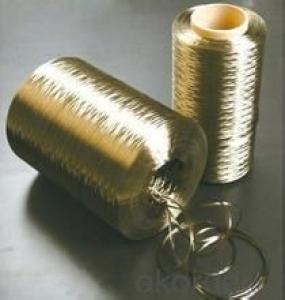

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Fiberglass Chopped StrandView More

Fiberglass Mesh ClothView More

Composite PipesView More

FRP Pultrusion ProfilesView More

Fiberglass Mat TissueView More

Fiberglass FabricsView More

Fiberglass MeshView More

Composite TankView More

Fiberglass Mesh tapeView More

PolymerView More

FRP Roofing PanelView More

Fiberglass RovingView More

Q & A

How do I create a mold for fiberglass?

To create a mold for fiberglass, start by designing or selecting the desired shape of the final fiberglass piece. Next, build a mold box around the shape using materials like wood or foam board. Apply a mold release agent to the inside of the mold box to prevent the fiberglass from sticking. Then, lay down layers of fiberglass cloth or mat inside the mold, saturating them with epoxy resin or polyester resin. Allow the resin to cure and harden before removing the mold box and extracting the fiberglass piece from the mold.

How does fiberglass perform in corrosive environments?

Fiberglass performs exceptionally well in corrosive environments. Its non-reactive nature makes it highly resistant to corrosion from chemicals, moisture, and other corrosive substances. Additionally, the smooth surface of fiberglass prevents the accumulation of contaminants, further enhancing its durability in corrosive conditions.

Can fiberglass supply be used for rapid prototyping?

Yes, fiberglass supply can be used for rapid prototyping. It is a versatile material that can be easily molded and used to create prototypes for various industries such as automotive, aerospace, and consumer products. Its strength, durability, and ability to be molded into complex shapes make it an ideal choice for creating functional prototypes quickly and efficiently.

Can fiberglass be used for making sculptures?

Yes, fiberglass can be used for making sculptures. It is a versatile material that is lightweight, durable, and can be molded into various shapes and sizes, making it ideal for creating intricate and large sculptures. Additionally, fiberglass is resistant to weathering and can withstand outdoor conditions, which further adds to its suitability for sculptural applications.

What are the different colors available for fiberglass?

The different colors available for fiberglass include white, black, gray, blue, green, red, yellow, and many more.

Wholesale Fiberglass Supply from supplier in France

Whether you are looking for fiberglass raw materials, such as fiberglass mats, rovings, or fabrics, or finished fiberglass products, such as fiberglass panels, pipes, or tanks, we have you covered. We work with trusted manufacturers to ensure that our customers receive high-quality products that meet their specific requirements.

In addition to our wide range of products, we also provide sales and technical support services. Our knowledgeable team is available to assist you in finding the right fiberglass supply products for your project and can provide guidance on installation, maintenance, and troubleshooting.

We understand the importance of timely and accurate quotations, and we strive to provide competitive prices for all our products. Our efficient procurement process ensures that you receive your orders on time, allowing you to meet your project deadlines.

As a subsidiary of CNBM, a global leader in the building materials industry, we benefit from their extensive resources and expertise. This enables us to provide comprehensive procurement services, from product selection to delivery, all under one roof.

Whether you are a construction company, a manufacturing firm, or a distributor, we are your trusted partner for all your fiberglass supply needs in France. Contact us today to discuss your requirements and discover how we can assist you in achieving your project goals.

In addition to our wide range of products, we also provide sales and technical support services. Our knowledgeable team is available to assist you in finding the right fiberglass supply products for your project and can provide guidance on installation, maintenance, and troubleshooting.

We understand the importance of timely and accurate quotations, and we strive to provide competitive prices for all our products. Our efficient procurement process ensures that you receive your orders on time, allowing you to meet your project deadlines.

As a subsidiary of CNBM, a global leader in the building materials industry, we benefit from their extensive resources and expertise. This enables us to provide comprehensive procurement services, from product selection to delivery, all under one roof.

Whether you are a construction company, a manufacturing firm, or a distributor, we are your trusted partner for all your fiberglass supply needs in France. Contact us today to discuss your requirements and discover how we can assist you in achieving your project goals.