All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

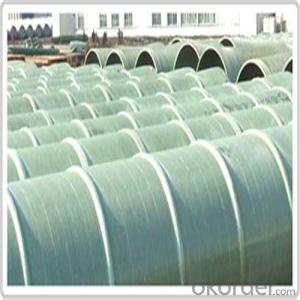

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

How do composite pipes handle thermal expansion and contraction?

Composite pipes handle thermal expansion and contraction by utilizing their unique material properties. Unlike traditional pipes made of metals, composite pipes have a lower coefficient of thermal expansion, meaning they expand and contract less when exposed to temperature changes. This allows them to better withstand the stresses caused by thermal expansion and contraction. Additionally, composite pipes often have layered structures that incorporate materials with different coefficients of thermal expansion, further reducing the overall effect of thermal expansion and contraction on the pipe.

Do composite pipes require insulation?

Yes, composite pipes typically require insulation. Insulation helps to prevent heat loss or gain, protects the pipes from extreme temperatures, and reduces condensation. It also improves energy efficiency and reduces the risk of pipe corrosion or damage.

Can composite pipes be used for thermal power plants?

Yes, composite pipes can be used for thermal power plants. Composite pipes, made from materials such as fiberglass, carbon fiber, or reinforced plastic, offer numerous advantages for thermal power plants. They possess high strength-to-weight ratio, corrosion resistance, and thermal insulation properties. These pipes can handle high temperatures and pressures, making them suitable for transporting hot water, steam, or other fluids in power plants. Additionally, composite pipes have a longer lifespan and require less maintenance compared to traditional metal pipes, making them a cost-effective and reliable choice for thermal power plants.

Wholesale Composite Pipes from supplier in Malawi

Whether you are in the water, oil and gas, or chemical industries, our Composite Pipes are designed to meet the highest standards of durability, performance, and reliability. Our pipes are made from a combination of materials, including fiberglass and resin, which provide excellent resistance to corrosion, chemicals, and high temperatures. This makes them ideal for use in harsh environments and ensures a long lifespan for your infrastructure.

In addition to our high-quality products, we offer a range of services to support your procurement process. Our dedicated sales team is available to assist you with any inquiries or requirements you may have. We provide detailed quotations that outline the specifications, pricing, and delivery information for your chosen products.

Furthermore, our technical support team is well-versed in the installation and maintenance of our Composite Pipes. They can provide guidance and expertise to ensure that your project is executed smoothly and efficiently. We understand the importance of timely and accurate technical support, and we are committed to assisting you at every step of the way.

As a subsidiary of CNBM, a Fortune Global 500 company, we have access to a vast network of resources and expertise. This allows us to offer competitive pricing, reliable delivery, and excellent customer service. We take pride in our ability to provide a seamless procurement experience for our customers in Malawi.

Contact us today to learn more about our Composite Pipes and how we can support your projects in Malawi. We look forward to working with you and helping you achieve success in your infrastructure endeavors.

In addition to our high-quality products, we offer a range of services to support your procurement process. Our dedicated sales team is available to assist you with any inquiries or requirements you may have. We provide detailed quotations that outline the specifications, pricing, and delivery information for your chosen products.

Furthermore, our technical support team is well-versed in the installation and maintenance of our Composite Pipes. They can provide guidance and expertise to ensure that your project is executed smoothly and efficiently. We understand the importance of timely and accurate technical support, and we are committed to assisting you at every step of the way.

As a subsidiary of CNBM, a Fortune Global 500 company, we have access to a vast network of resources and expertise. This allows us to offer competitive pricing, reliable delivery, and excellent customer service. We take pride in our ability to provide a seamless procurement experience for our customers in Malawi.

Contact us today to learn more about our Composite Pipes and how we can support your projects in Malawi. We look forward to working with you and helping you achieve success in your infrastructure endeavors.

Hot Search

- Fiberglass Chopped Strand in South Korea

- Fiberglass Mesh Cloth in India

- Composite Pipes in Mali

- FRP Pultrusion Profiles in Belarus

- Fiberglass Mat Tissue in Iraq

- Fiberglass Fabrics in Spain

- Fiberglass Mesh in Barbados

- Composite Tank in Ireland

- Fiberglass Mesh tape in United Arab Emirates

- Polymer in Jamaica